Bauxite coarse-fine separation grinding method

A process method and bauxite technology are applied in the field of bauxite grinding process, bauxite coarse and fine separation grinding process, and can solve the problems of waste of mill capacity, reduction of red mud settling performance, power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

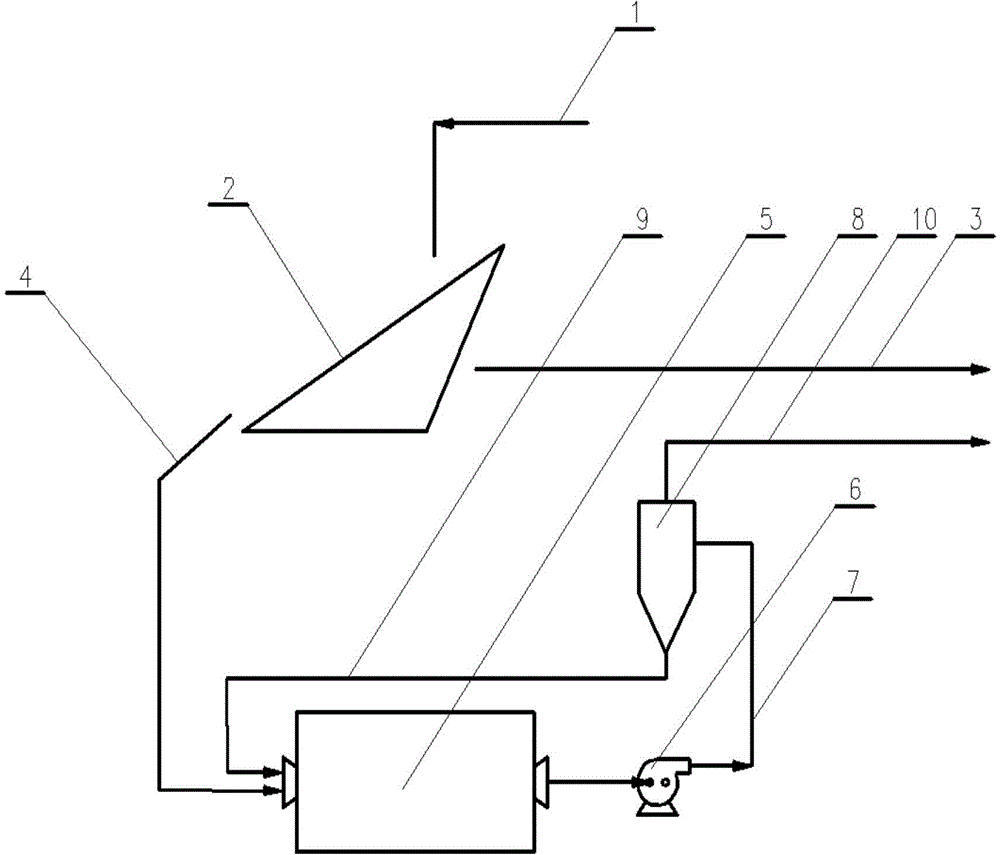

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

[0020] like figure 1 As shown, the mixed slurry 1 obtained after the bauxite and the lye are fully mixed is sent to the fine screen 2 through a chute or a pipeline. Under the high-frequency vibration of the fine screen 2, the bauxite smaller than the mesh size in the mixed pulp 1 passes through the screen, and the lye that passes through the screen is sent to the next process as the under-sieve pulp 3. The ore 4 on the screen is fed into the mill 5 through a chute or flow pipe. Under the grinding action of the mill, the particle size of the bulk bauxite is further reduced. Under the action of the slurry pump 6, the milled pulp 7 is sent to the hydrocyclone 8 for classification. The cyclone sand returning 9 with unqualified particle size is returned to the mill 5 for grinding again, and the cyclone with qualified particle size overflows 10 and is sent to the next pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com