An inner double-inlet multi-stage separation vacuum cleaner

A multi-stage separation and vacuum cleaner technology, applied in vacuum cleaners, suction filters, household appliances, etc., can solve the problem of poor dust separation effect, and achieve the effect of strengthening centrifugal separation effect, good air intake balance, and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

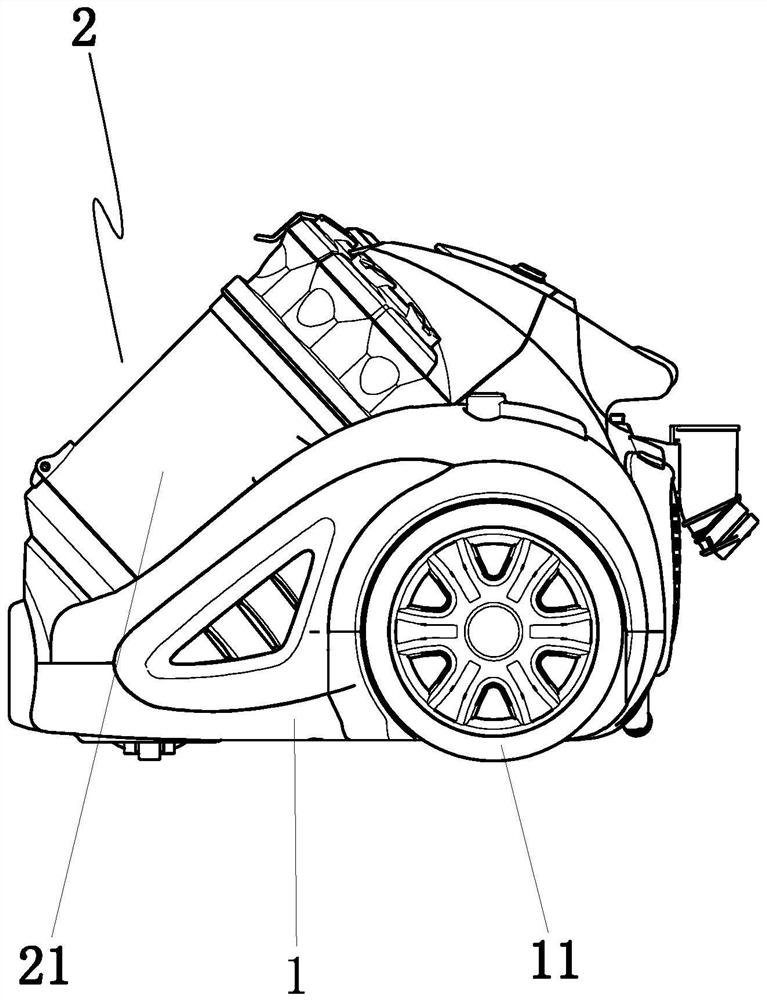

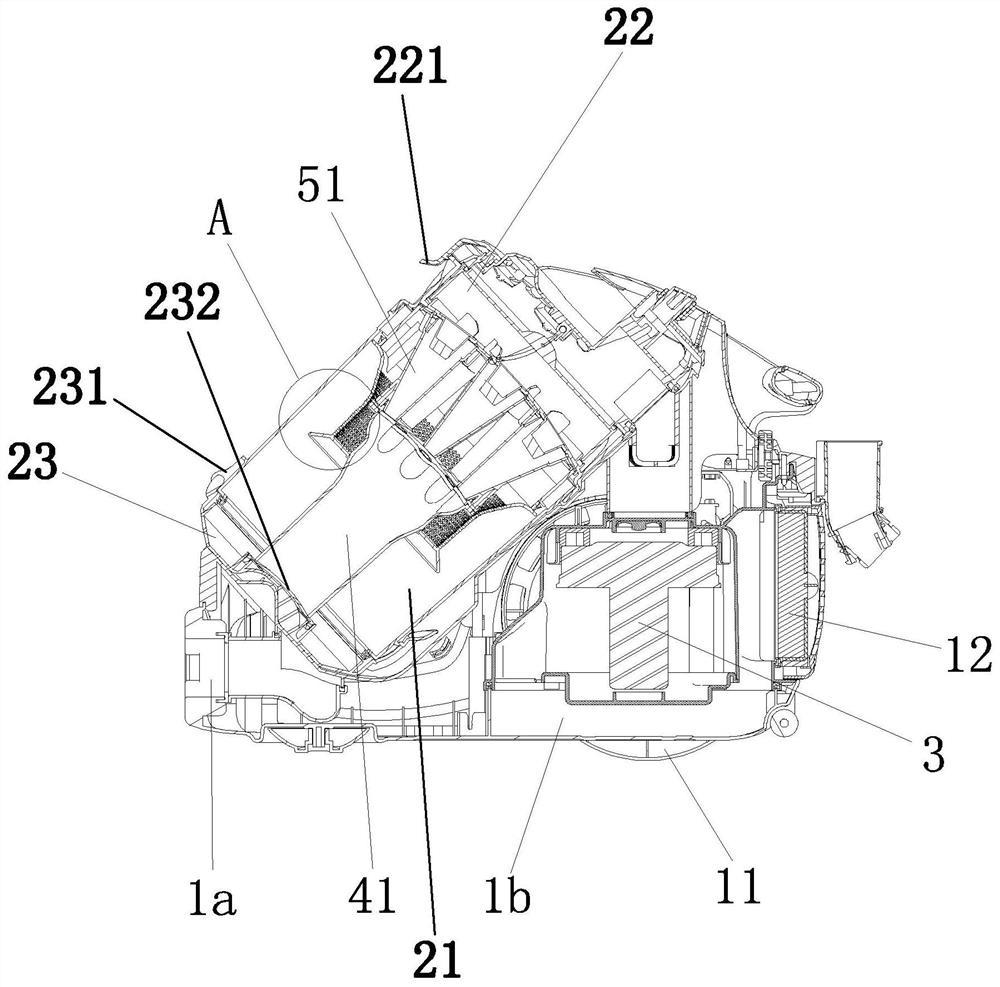

[0031] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as shown in

[0032] An inner double-inlet multi-stage separation vacuum cleaner, including

[0033] The casing 1, the dust cup 2 and the vacuum motor 3; the dust cup includes a cup body 21, a cup cover 22 and a bottom cover 23, the cup cover is snapped to the cup body, and the bottom cover is snapped to the cup body;

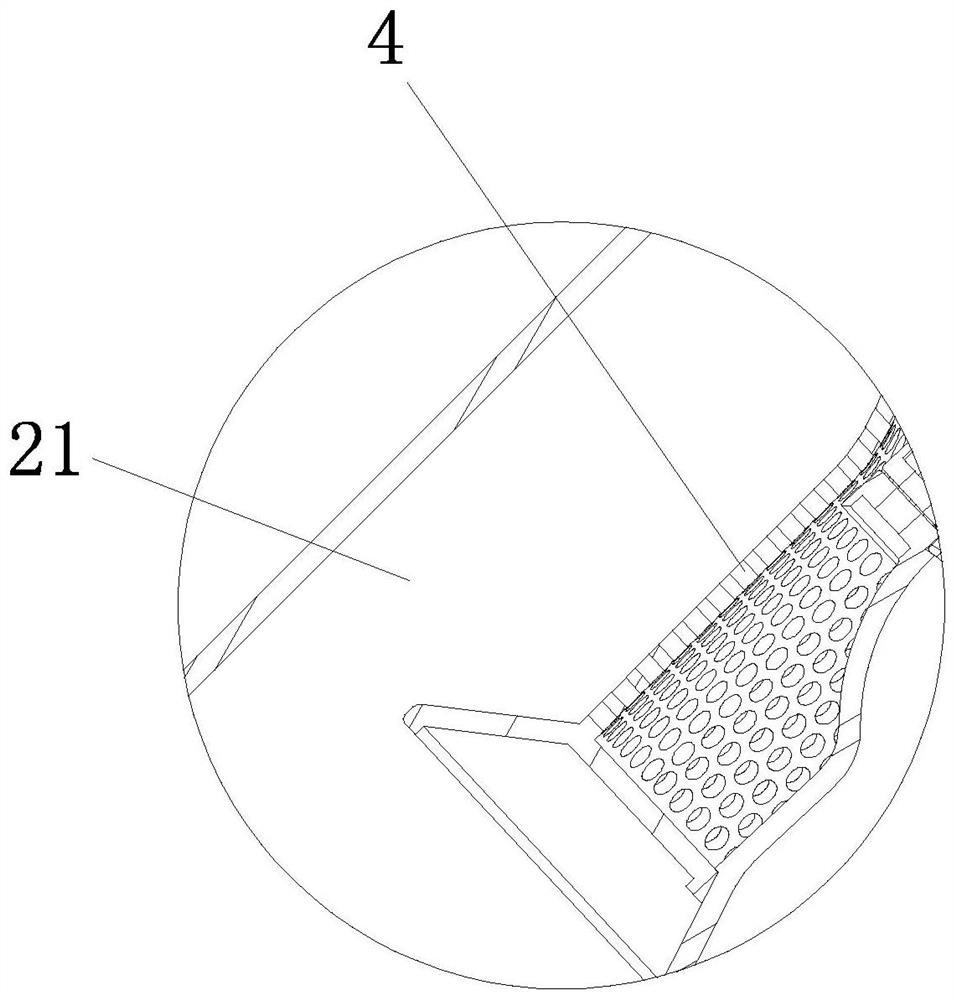

[0034] The dust cup is provided with a first air inlet and a first air outlet, and a filter cartridge 4 and a secondary separator are arranged in the cup body, the secondary separator separates the cup cover from the cup body, and the secondary separator includes multiple A cyclone separation cone 51, the diameter of the lower port of the cyclone separation cone is smaller than the diameter of the upper port, the side wall of the cyclone separation cone is provided with two tangential air inlet pipes inside the cup cover, and the lower end of the cyclone separation cone communi...

Embodiment 2

[0045] Embodiment 2: based on embodiment 1, such as Figure 6 as shown,

[0046] It also includes a mop 6, an elastic bellows and an operating hard tube 7. The mop is provided with a mop chamber 6a, and the mop is provided with a bottom suction port 6b connected with the mop chamber and an upper suction port connected with the mop chamber. Air outlet pipe 61, the lower end of the operating hard pipe is snapped and communicated with the upper air outlet pipe, the upper end of the operating hard pipe is snapped and communicated with one end of the elastic bellows, and the other end of the elastic bellows is snapped and communicated with the main suction port. A ground mop front wheel and two coaxially arranged ground mop rear wheels 62 are provided on the top. When using a vacuum mop, you can hold the operating hard tube to drive the vacuum mop to move on the ground, thereby vacuuming everywhere.

Embodiment 3

[0047] Embodiment 3: based on embodiment 2, such as Figure 7 , Figure 8 , Figure 9 , Figure 10 as shown,

[0048] The lower part of the front end of the dust-absorbing floor mop is provided with a front suction hole 6c, and the front suction hole is provided with a horizontal column 63 that is slidingly and sealingly matched with the front suction hole. The horizontal column includes an inner guide hemispherical head 631, a column body 632 and an outer Guide hemispherical head 633, the mop cavity is provided with a sealing plate 64 for sealing the bottom suction port, the side of the sealing plate adjacent to the front suction hole is hinged with the inner bottom surface of the vacuum mop, and the inner guiding hemispherical head is provided with a sealing plate for pressing down The pressure plate 65, there is a margin gap between the pressure plate and the sealing plate, a connecting rope 66, a rope spring 67, a slider 681 connected with the pressure plate and a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com