Patents

Literature

32results about How to "Improve centrifugal separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

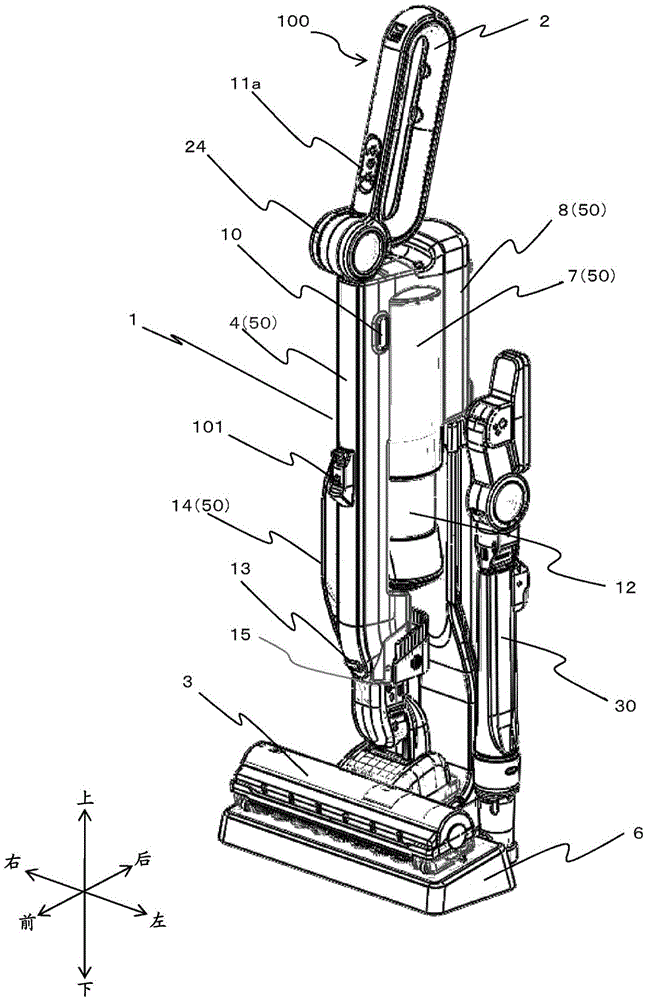

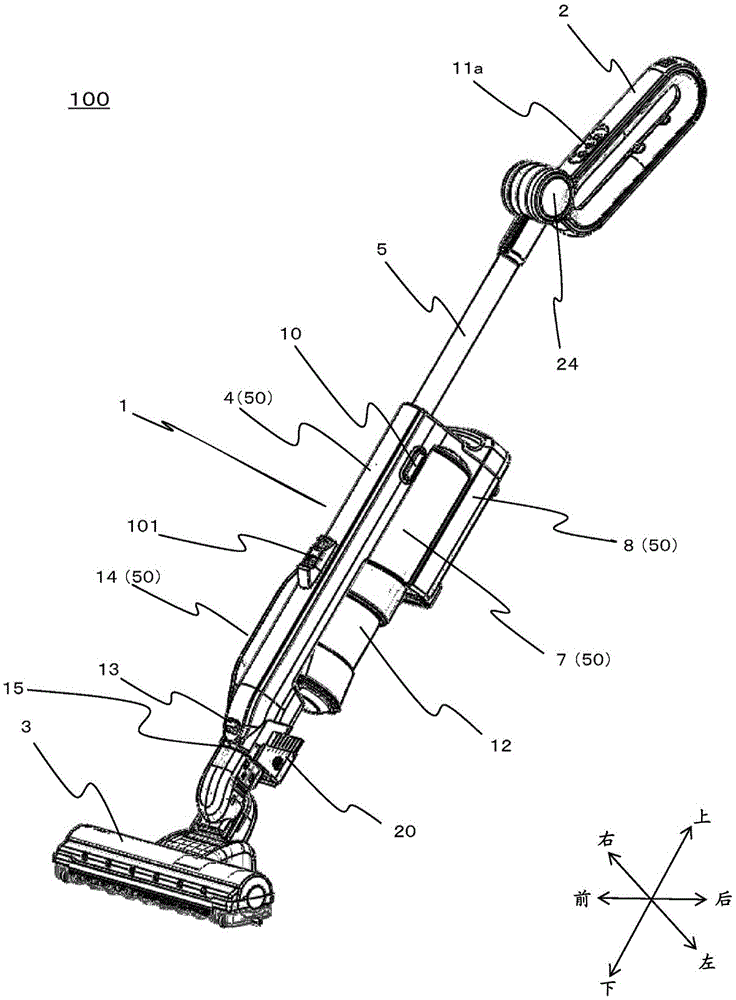

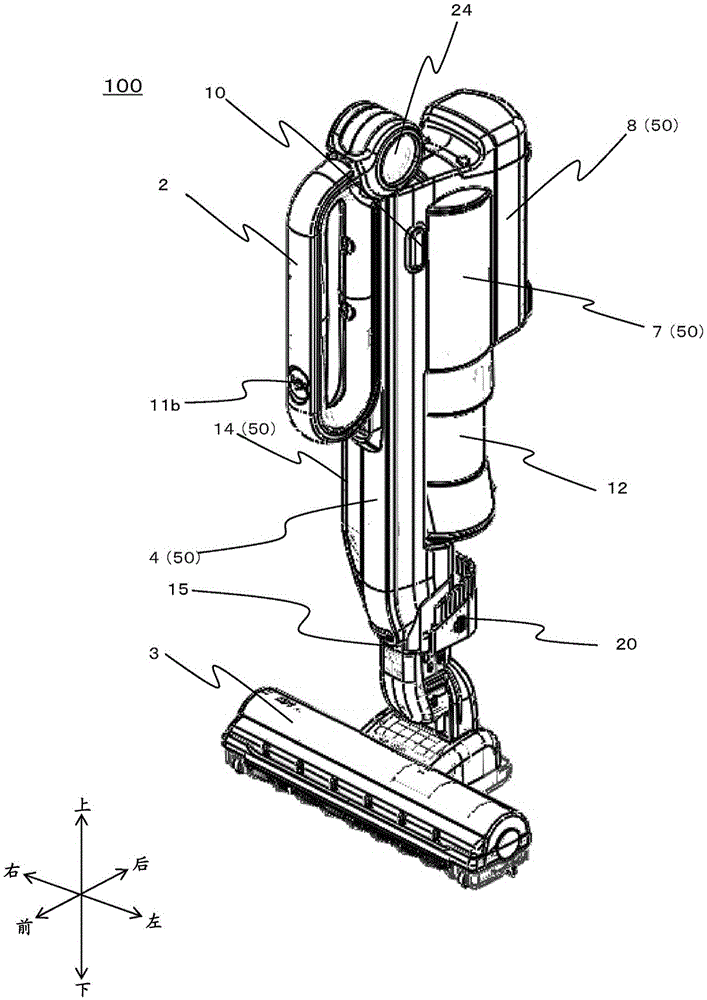

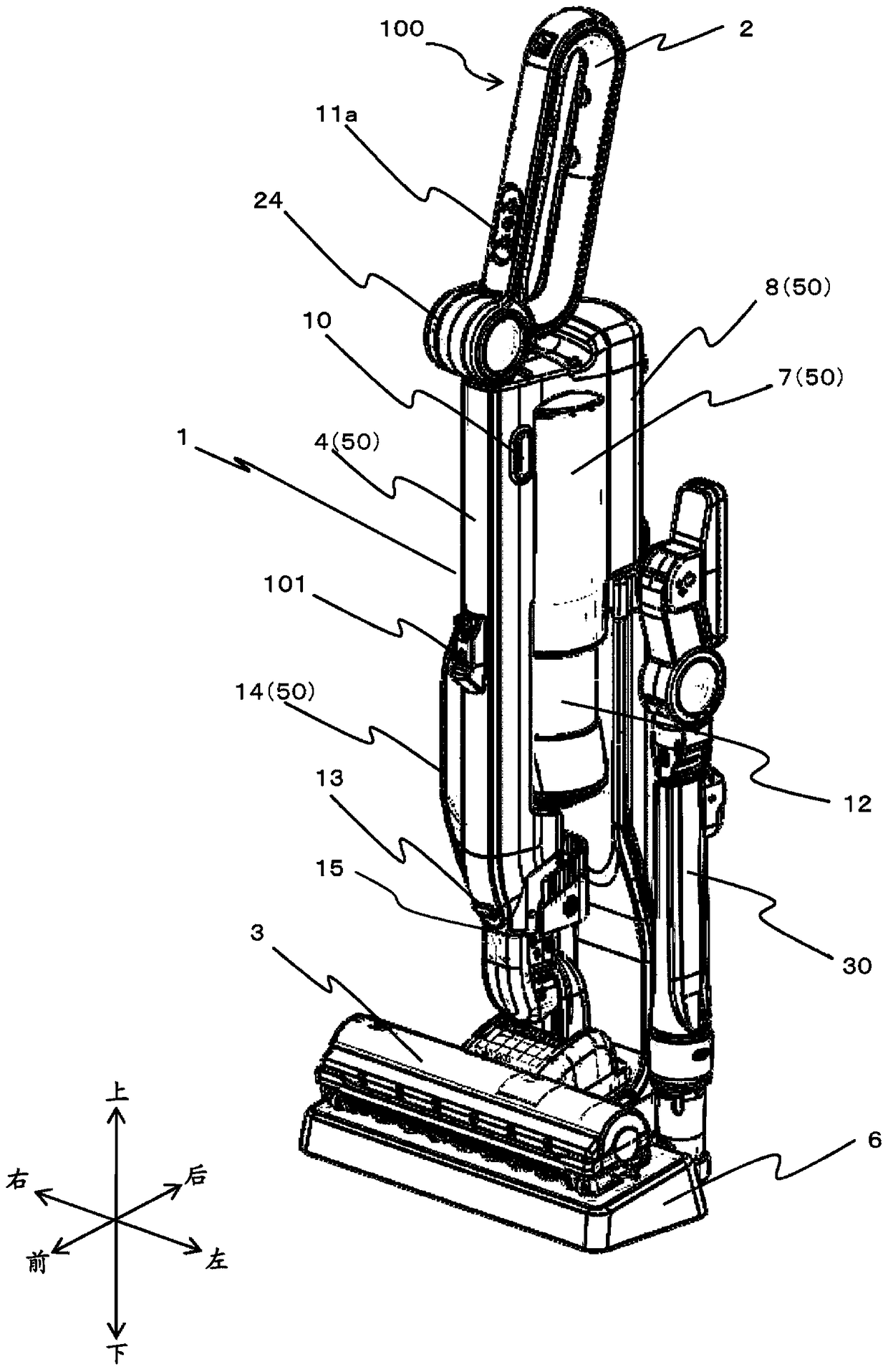

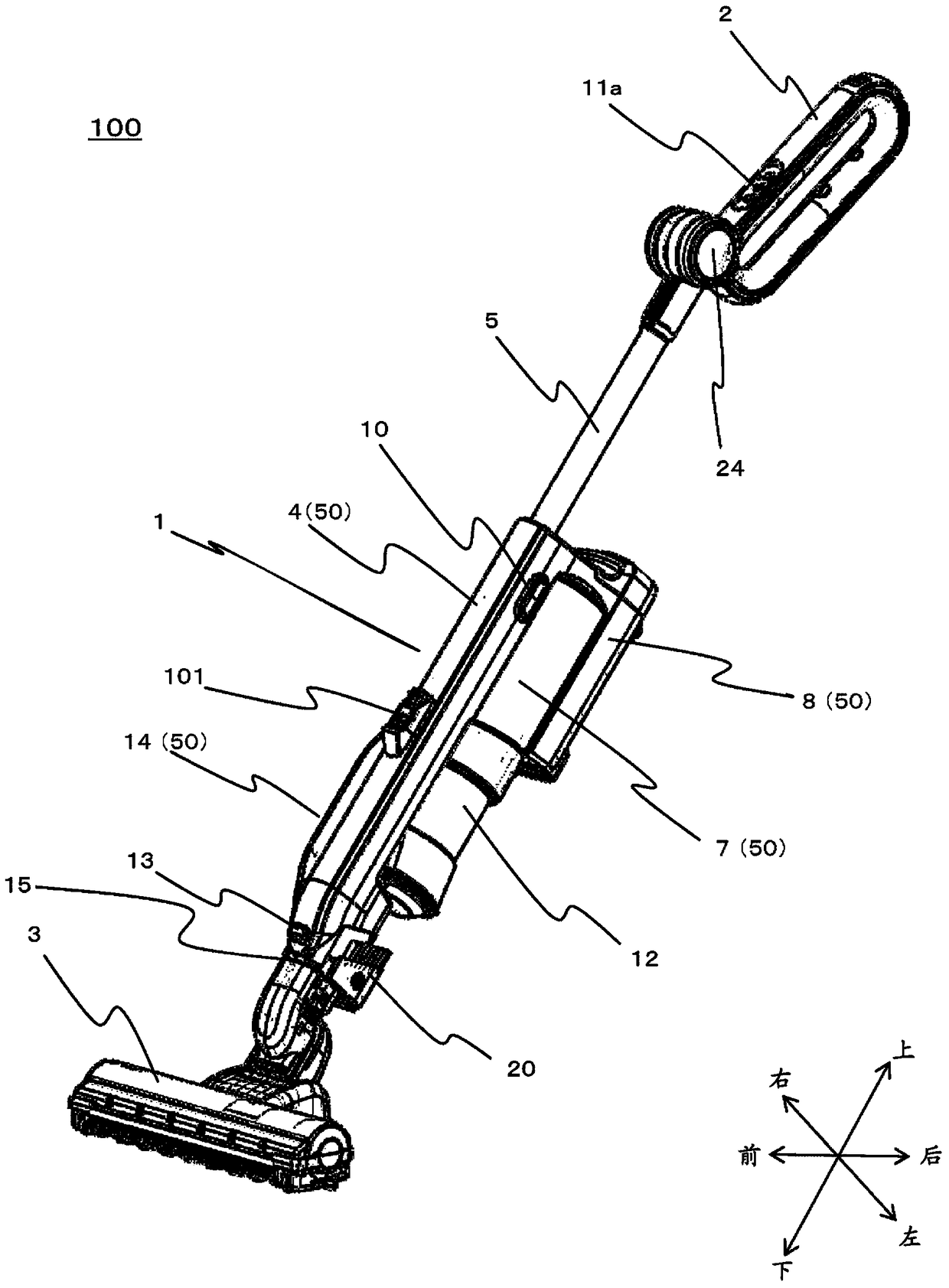

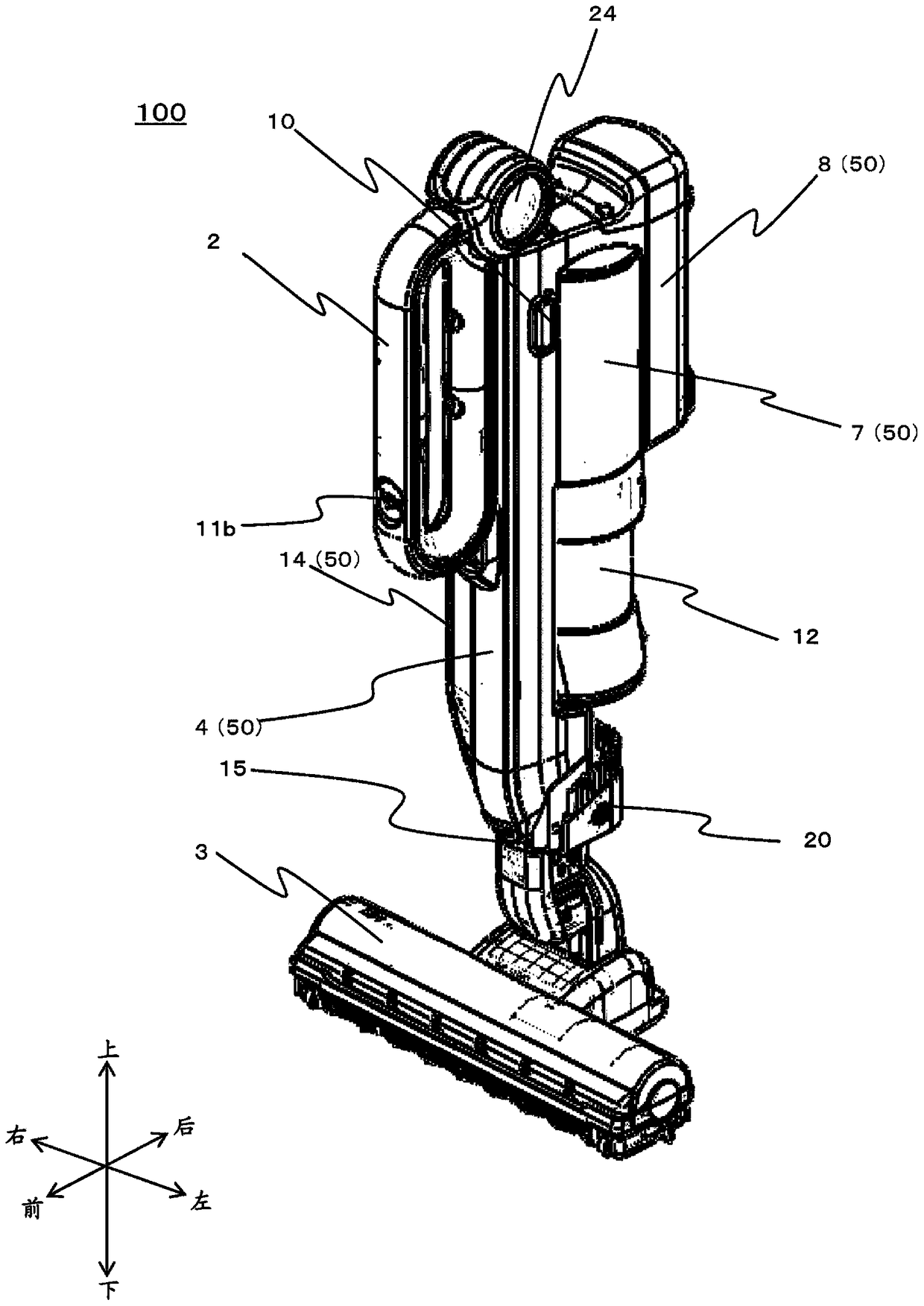

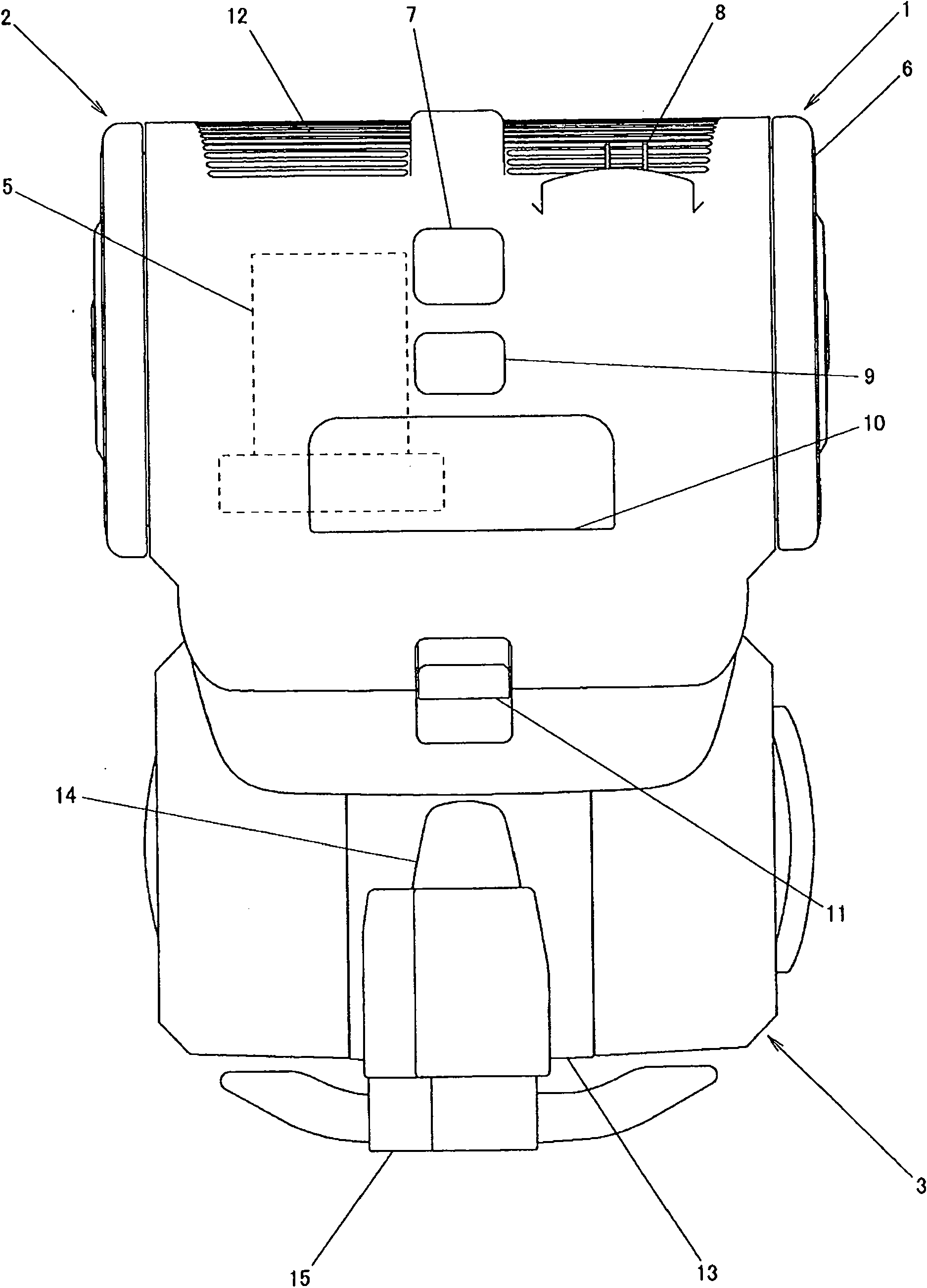

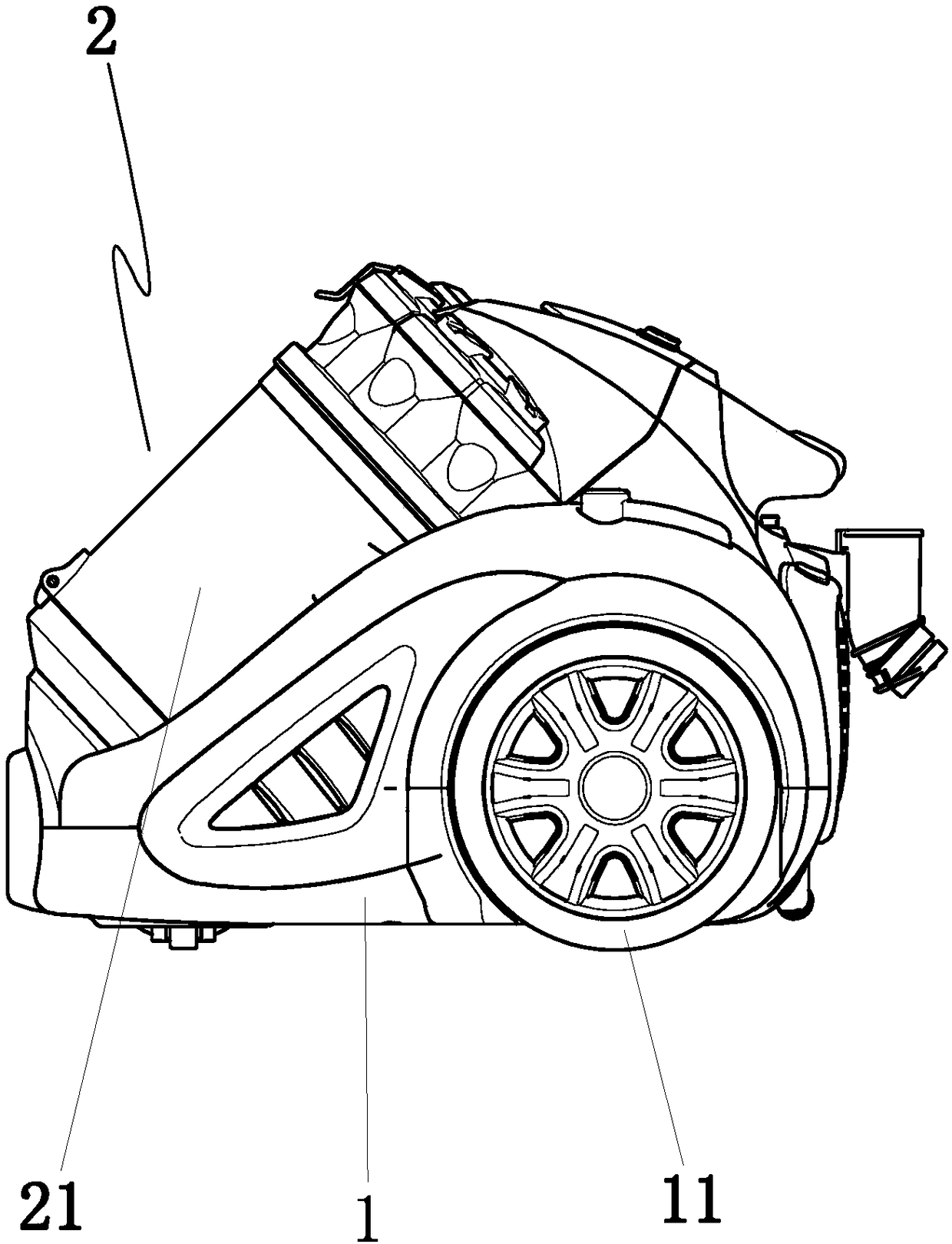

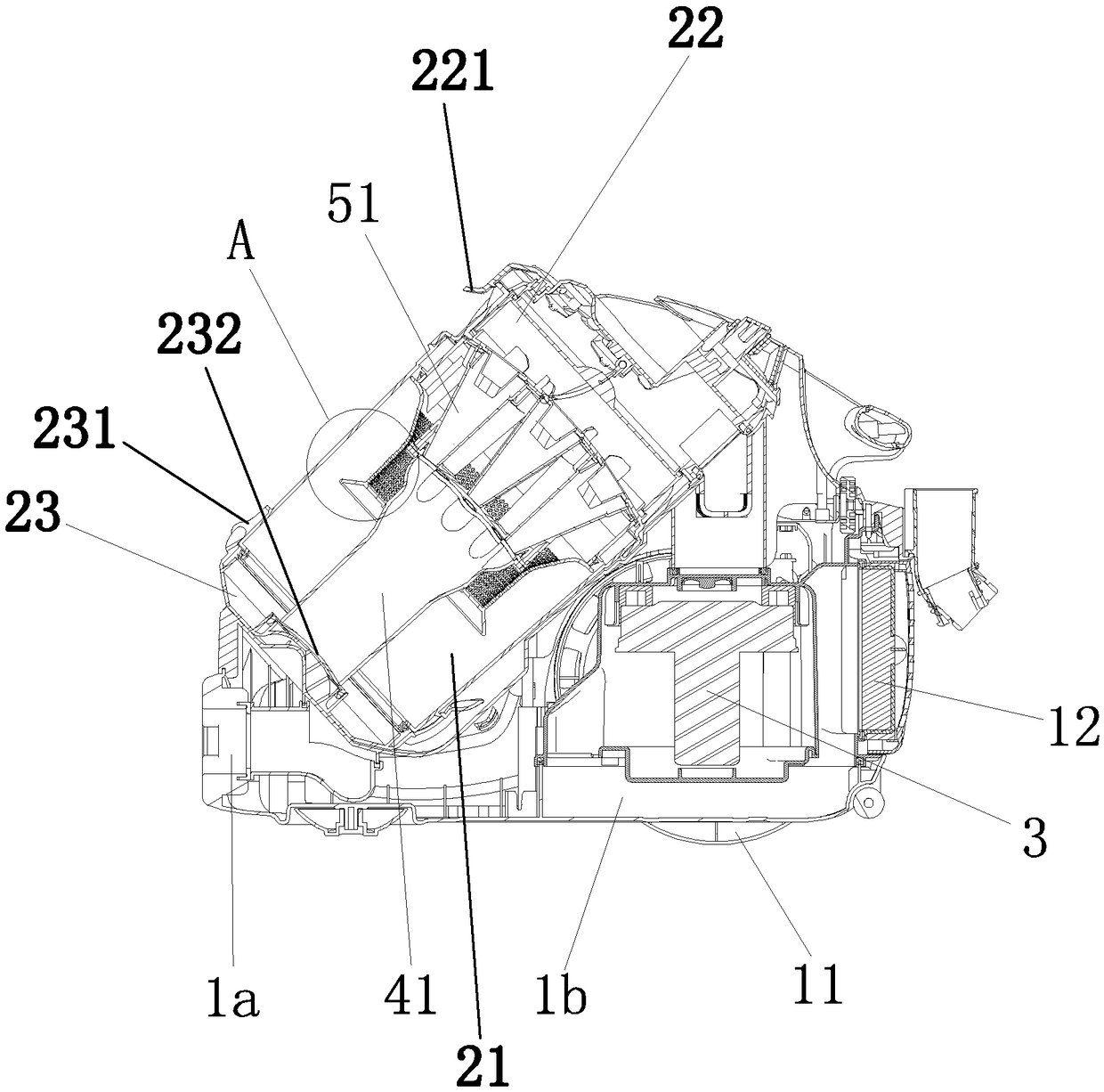

Electric dust collector

ActiveCN105816101AImprove centrifugal separation effectShorten the upper and lower lengthSuction filtersDust collectorWaste management

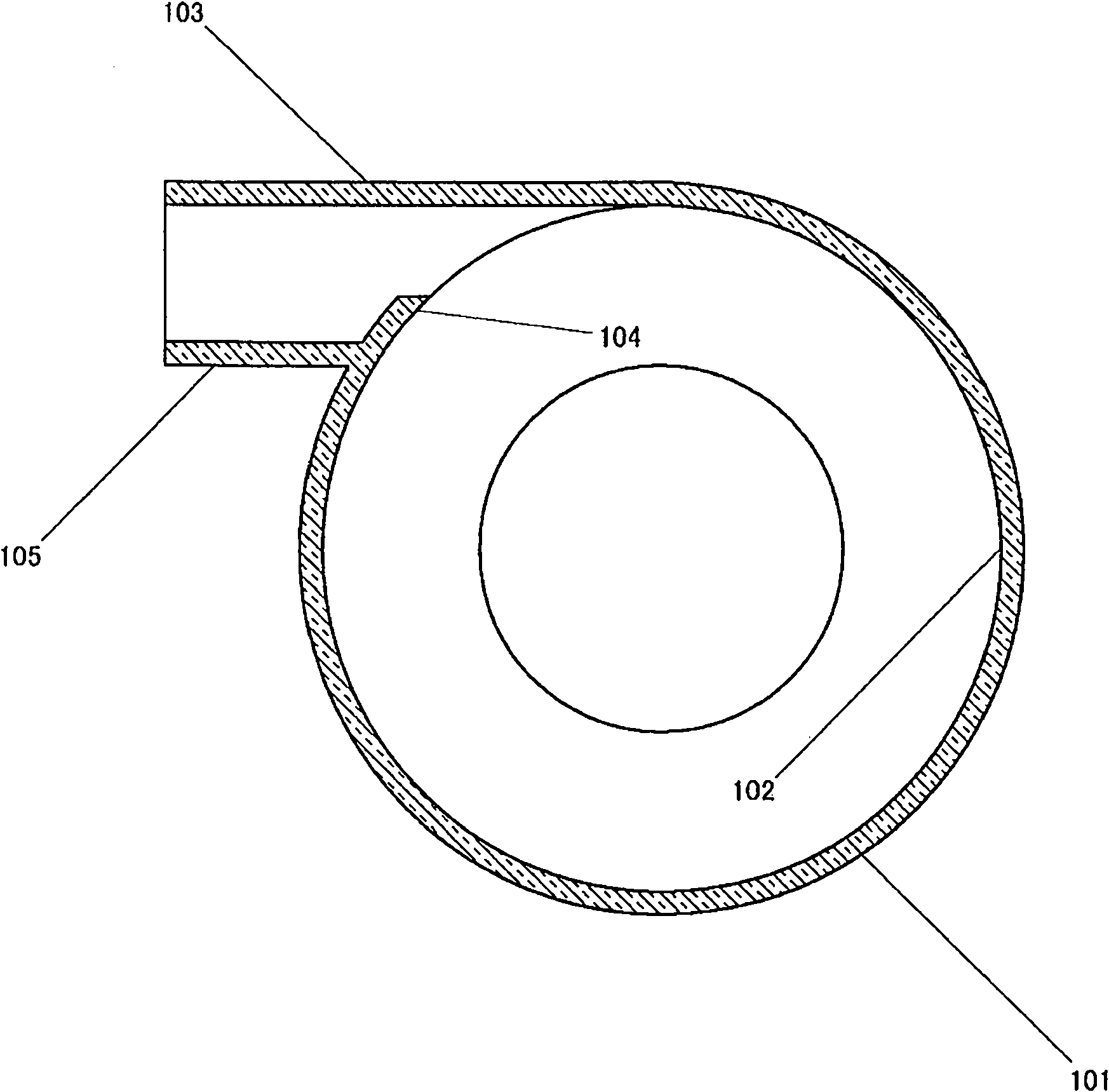

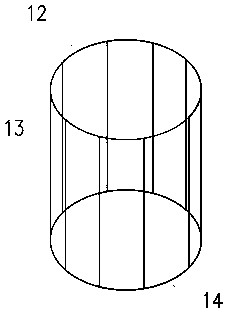

The invention provides an electric dust collector usable in both a rod type and a portable type. The electric dust collector has a whirlwind dust collection device capable of maintaining an absorption force, has a dust centrifugal separation function, is miniature and light, and is convenient to use. The electric dust collector has a dust collector main body. The dust collector main body has an electric fan, an absorption port and the dust collection device. The dust collection device is provided with a basically cylinderical outer cylinder, and an inner cylinder arranged in the basically cylinderical outer cylinder. The inner cylinder and the outer cylinder are roughly configured in a concentric manner. The outer cylinder is provided with an inflow port at the side part. The inflow port is communicated with one end of a guiding tube. The guiding tube is arranged in the dust collector main body and are open on two ends. The absorption port is arranged on the other end of the guiding tube. The guiding tube is arranged on the side part of the dust collection device. The absorption is arranged between the guiding tube and the dust collection device.

Owner:HITACHI APPLIANCES INC

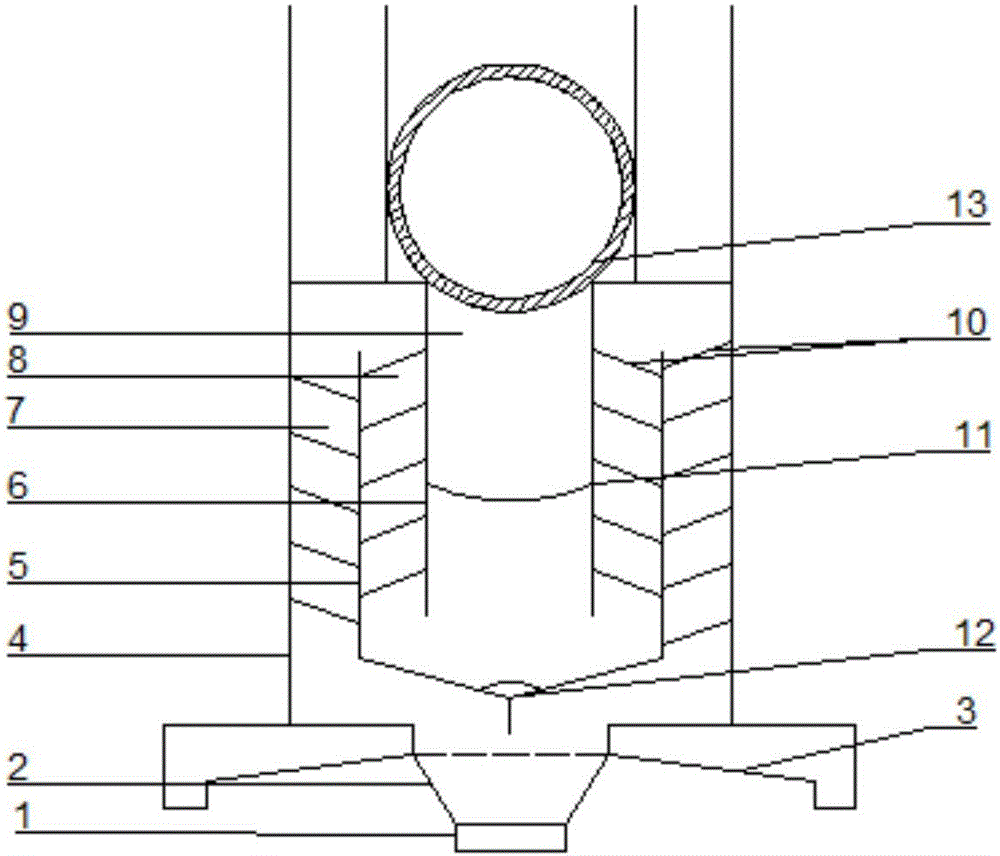

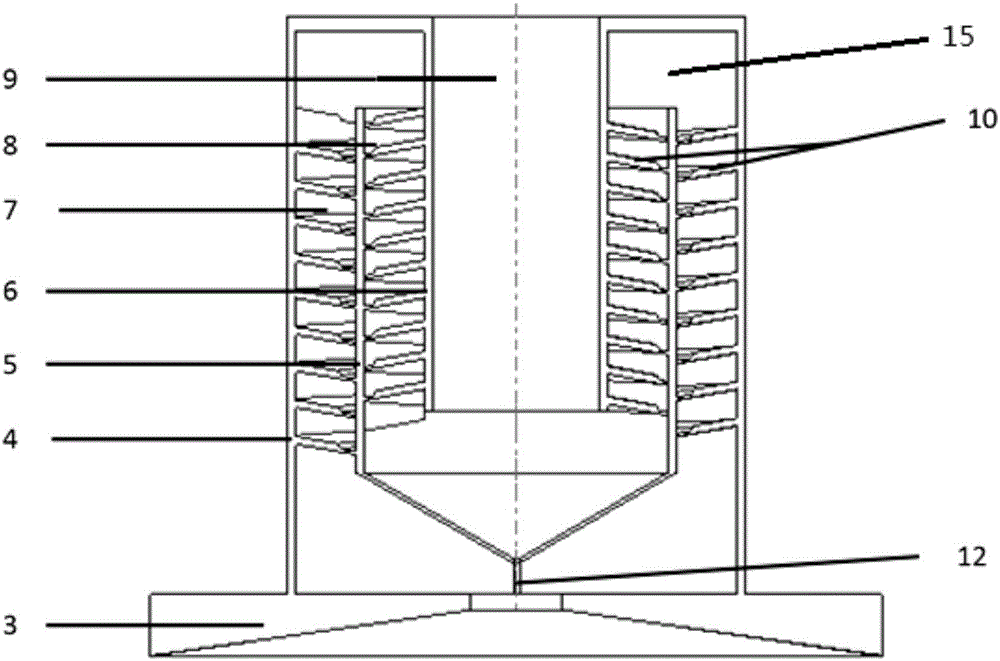

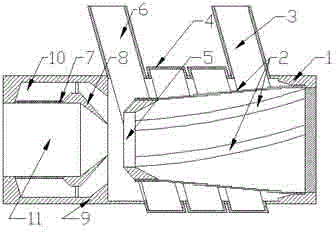

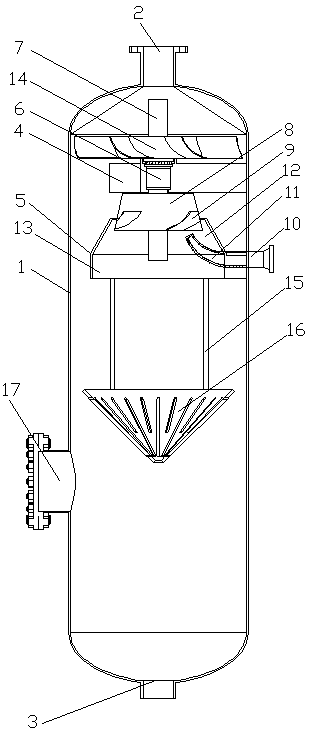

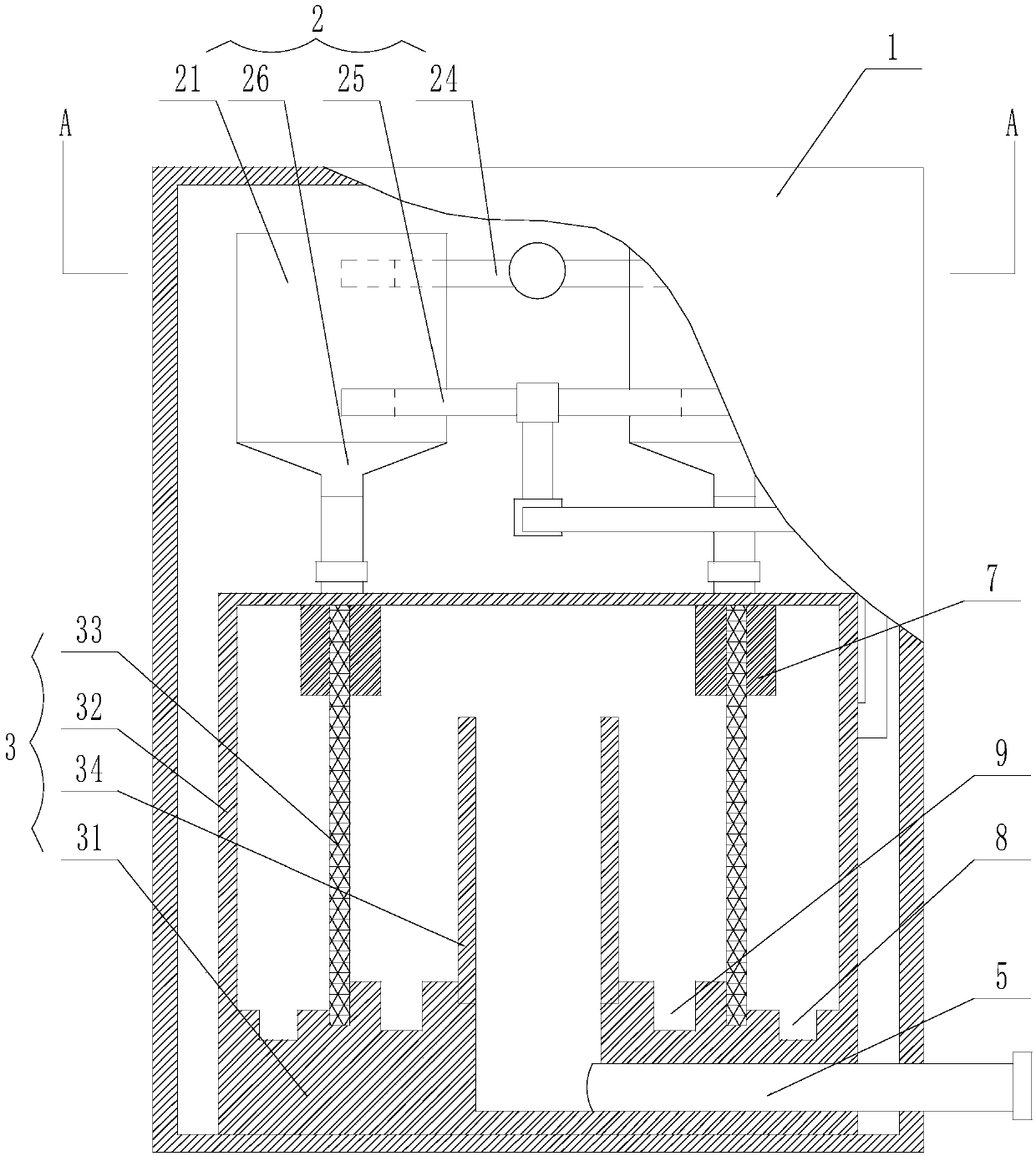

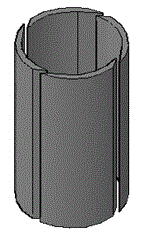

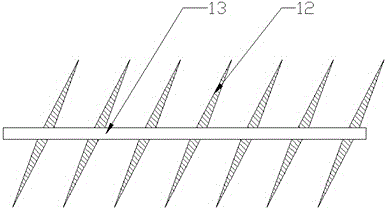

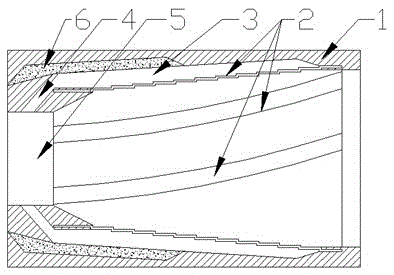

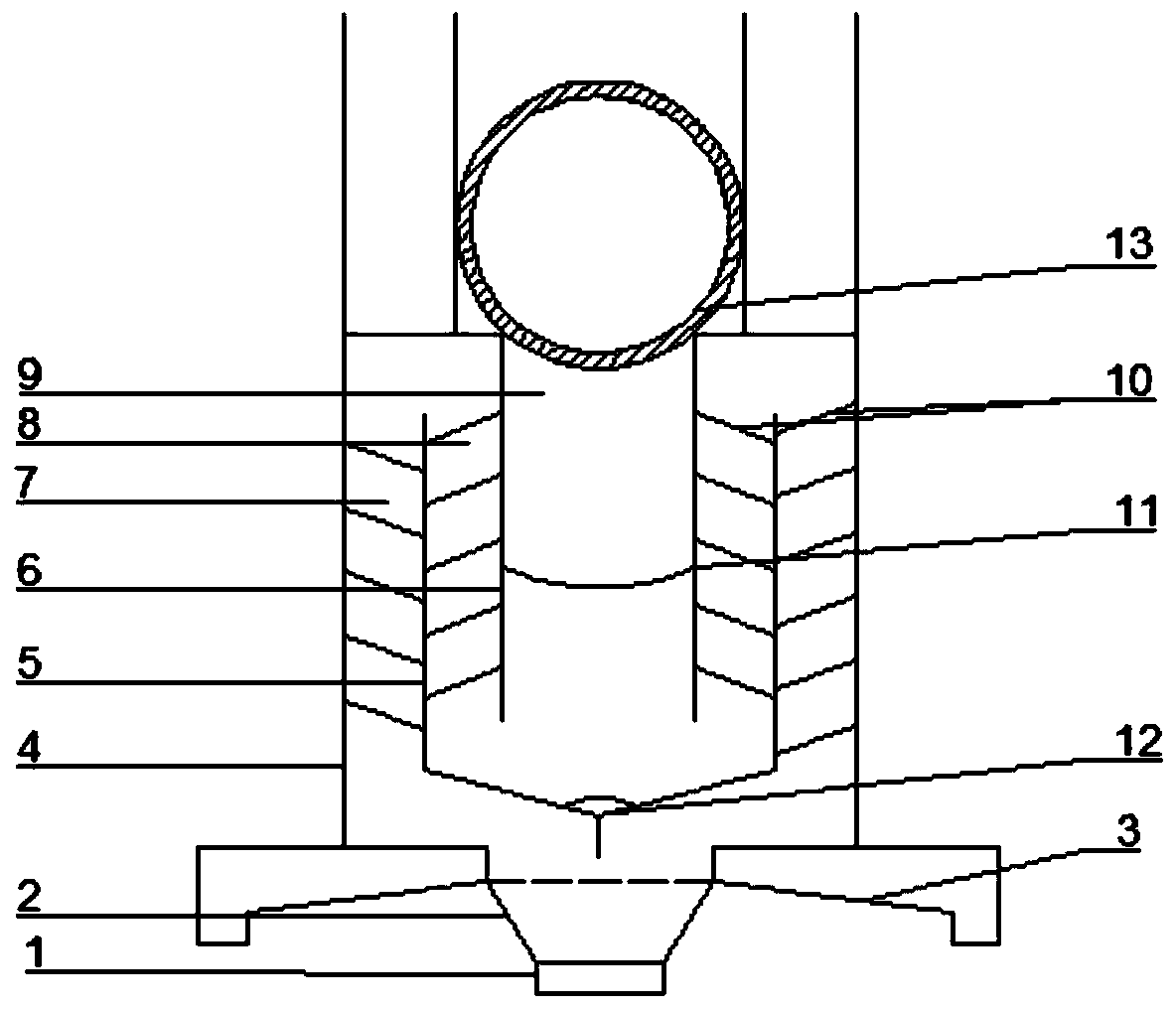

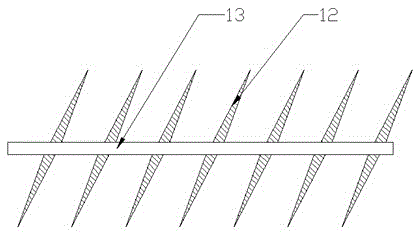

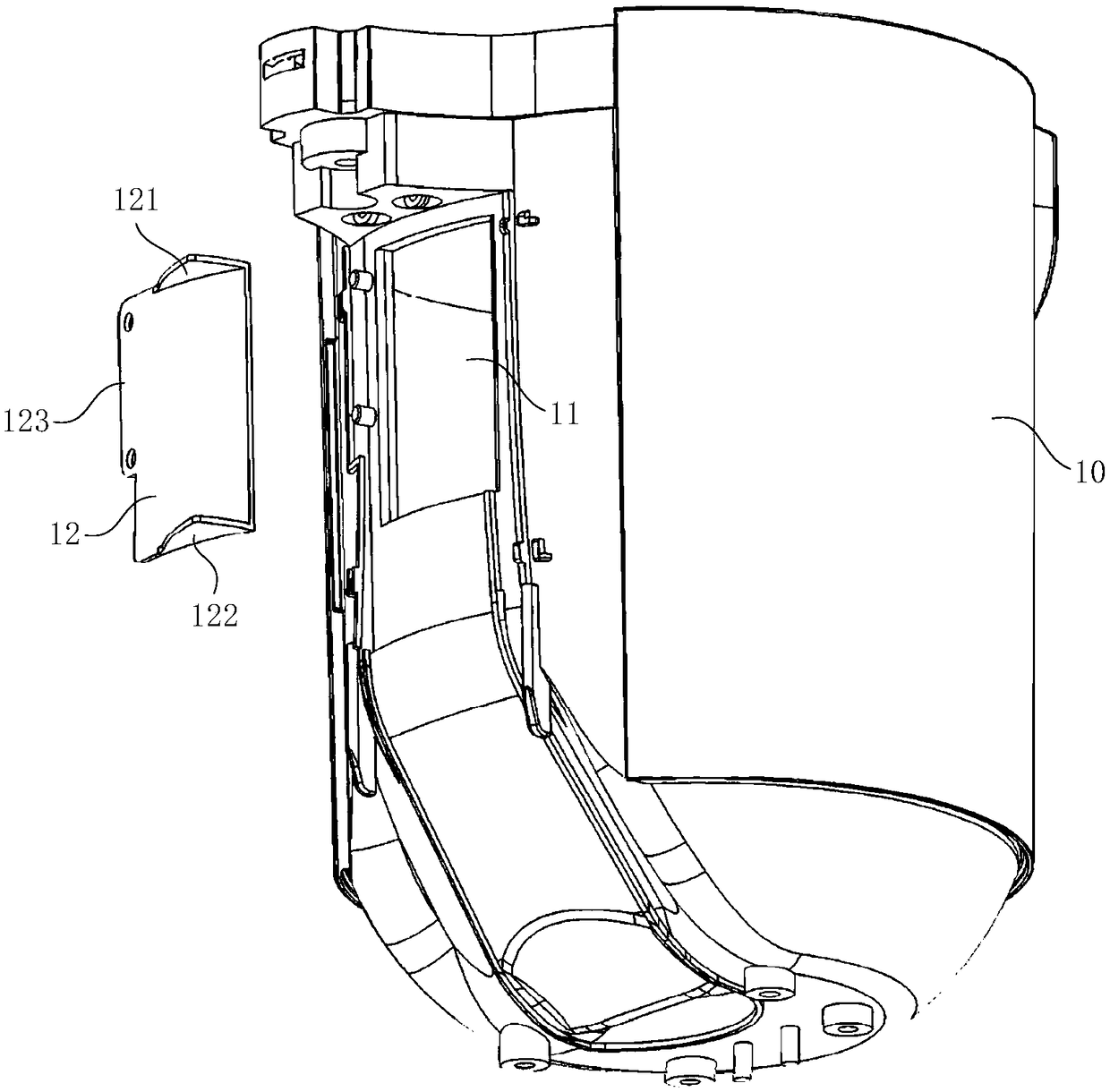

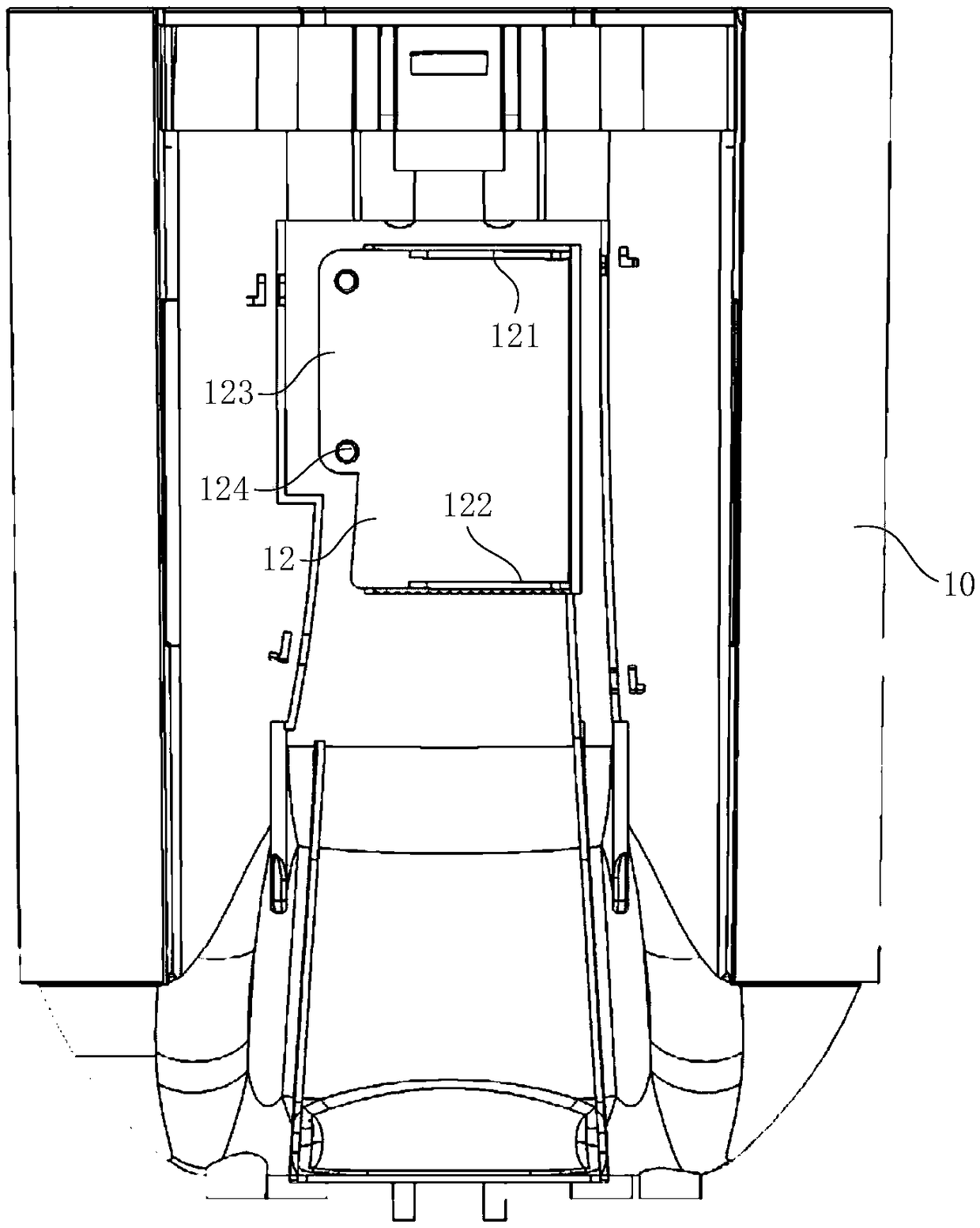

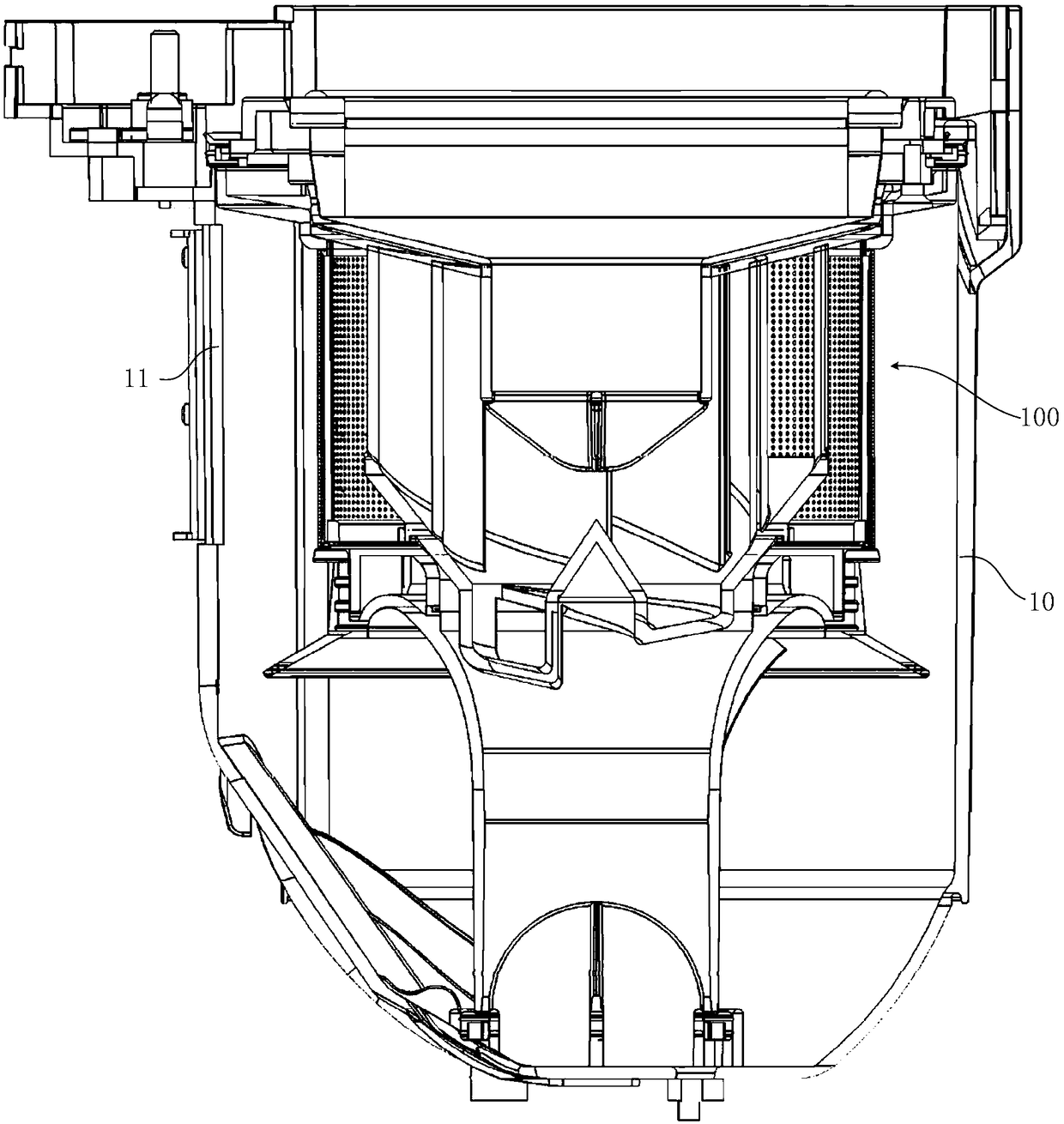

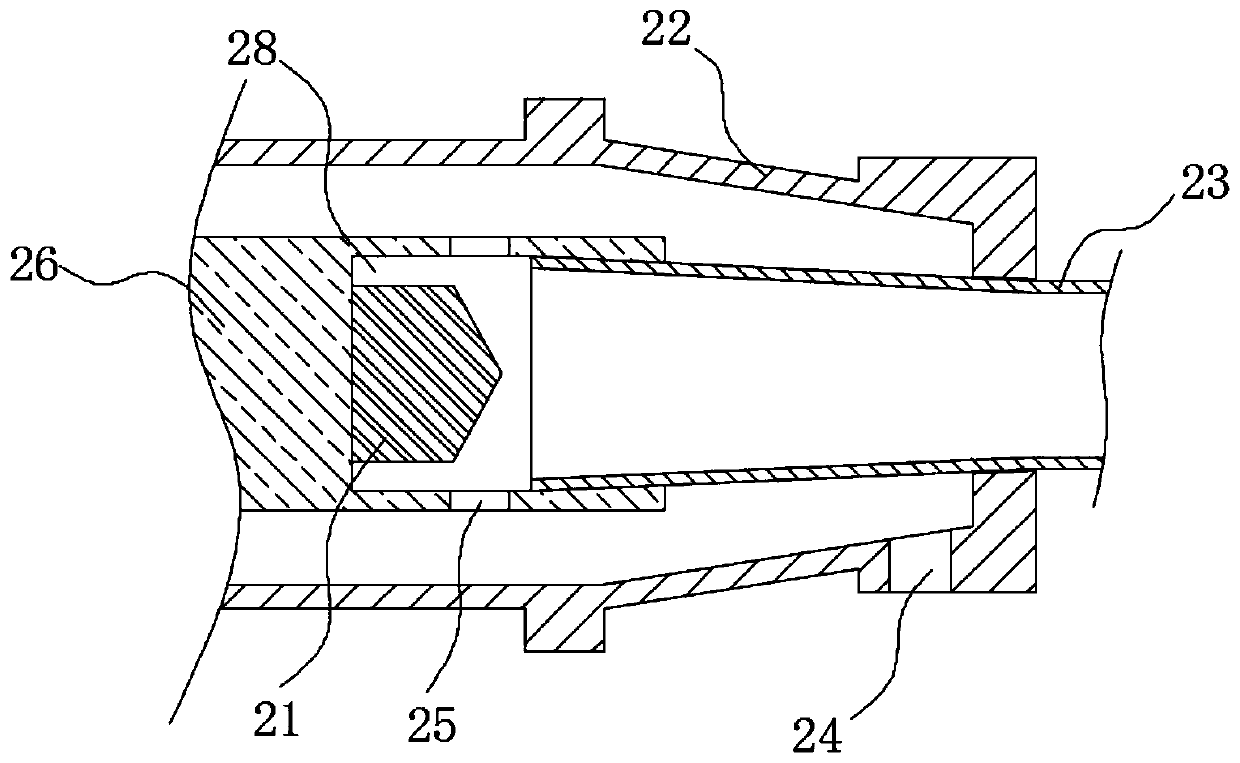

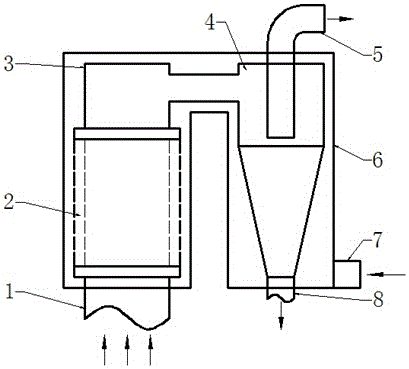

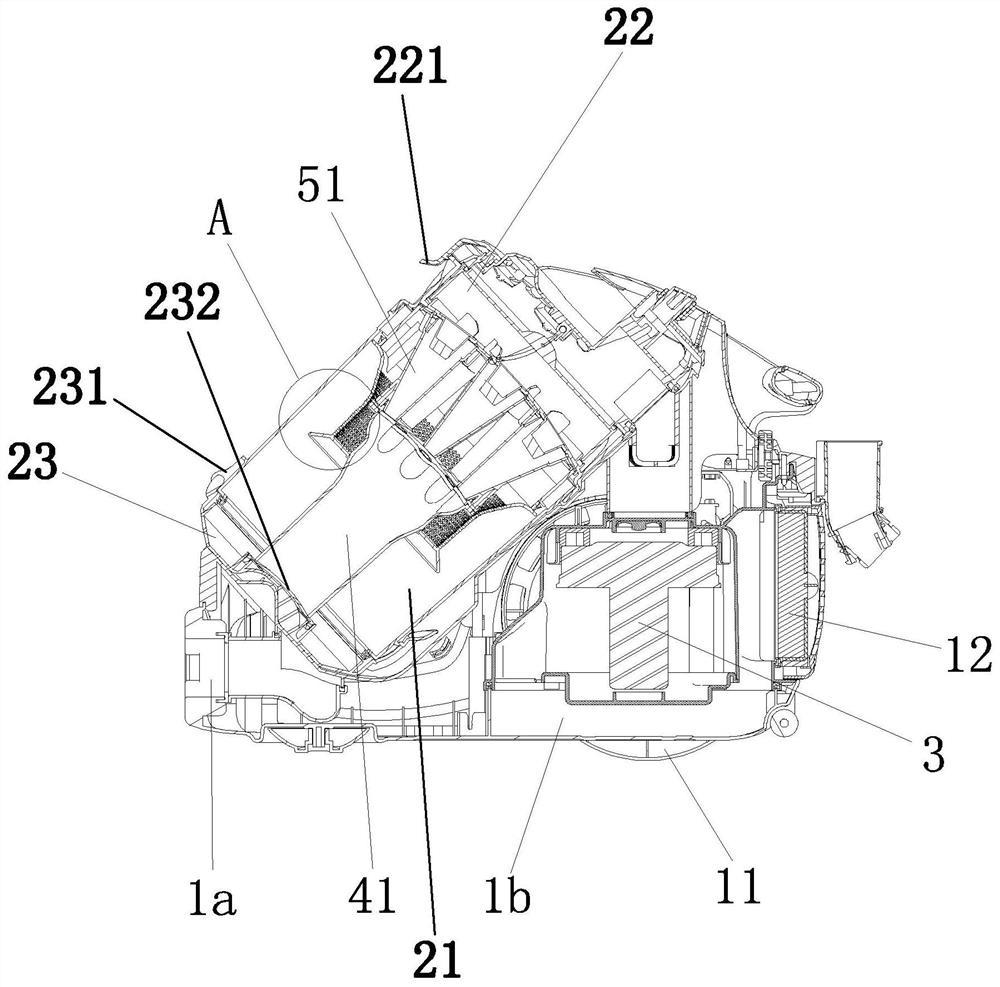

High-grease-separation-degree extractor hood and built-in spiral separation device thereof

ActiveCN106813281AIncrease cooling areaEasy to separateDomestic stoves or rangesLighting and heating apparatusOil and greasePulp and paper industry

The invention provides a high-grease-separation-degree extractor hood and a built-in spiral separation device thereof. The built-in spiral separation device comprises an inner shell, a cylinder and spiral plates; the inner shell is connected with the interior of an outer shell of an overall machine of the extractor hood; the outer edge of the upper end of the inner shell and the interior of the outer shell of the overall machine are in sealed connection, a ventilating duct for smoke discharging is formed in the middle portion of the inner shell, and a flue is formed by the outer side of the inner shell and the outer shell of the overall machine; the top of the cylinder is connected with the inner shell, at least one ventilating opening is formed in the periphery of the top of the cylinder, and the bottom of the cylinder is closed and is provided with an oil collecting pipe; the cylinder is vertically fixed into the flue and divides the flue into an outer side flue close to the outer shell of the overall machine and an inner side flue close to the inner shell; the outer side flue is communicated with a smoke inlet of the extractor hood, and the inner side flue is communicated with the ventilating duct; and the spiral plates are fixedly installed on the inner side and the outer side of the cylinder correspondingly. The smoke inlet of the extractor hood is communicated with a smoke outlet of the extractor hood through the outer side flue, the ventilating openings, the inner side flue and the ventilating duct in sequence.

Owner:XI AN JIAOTONG UNIV

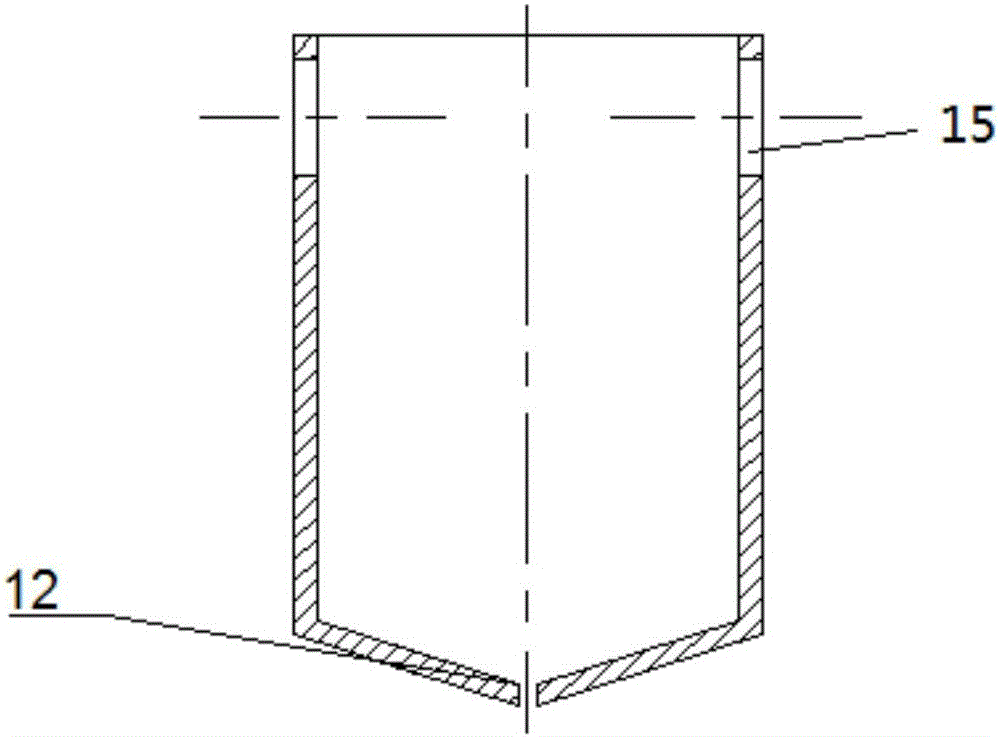

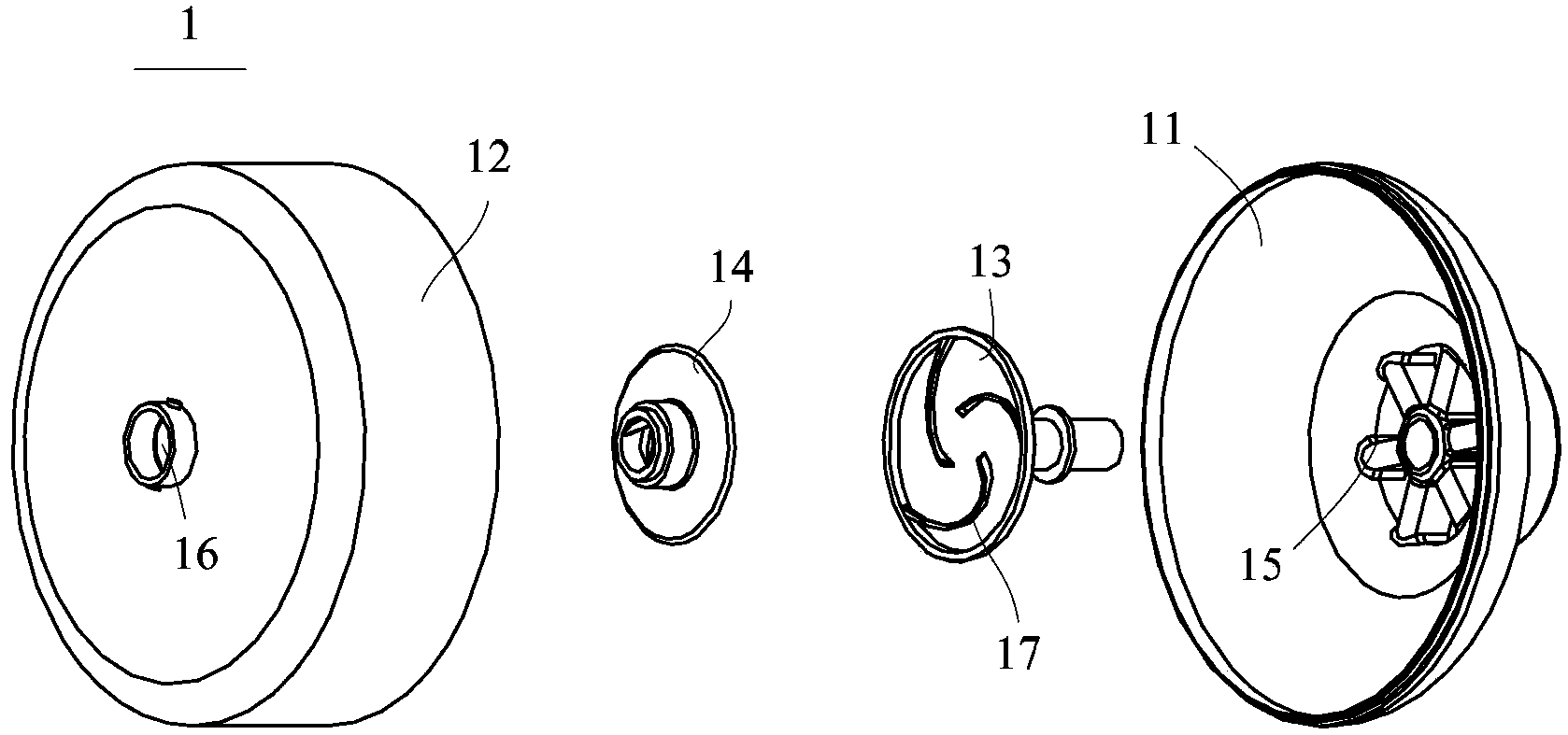

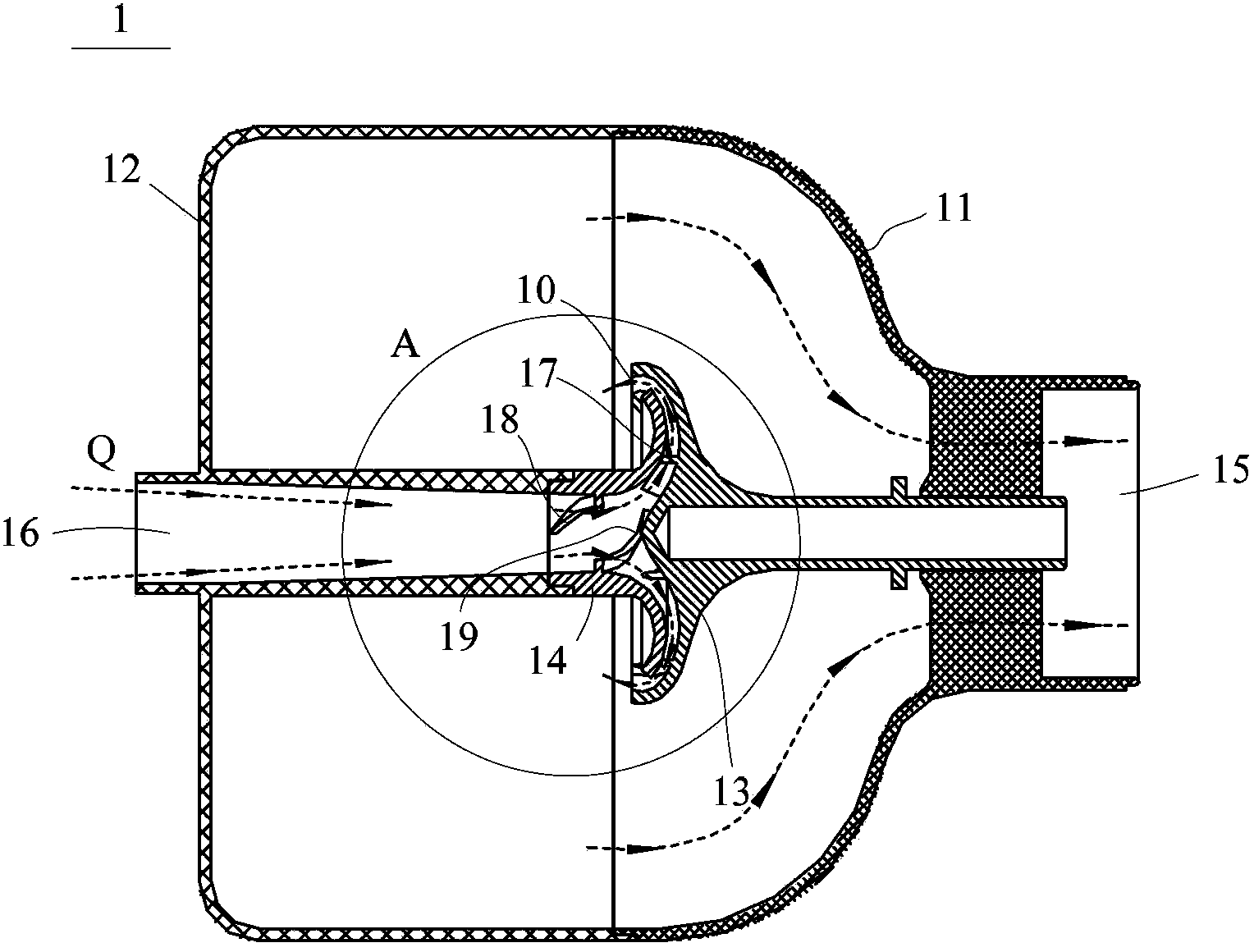

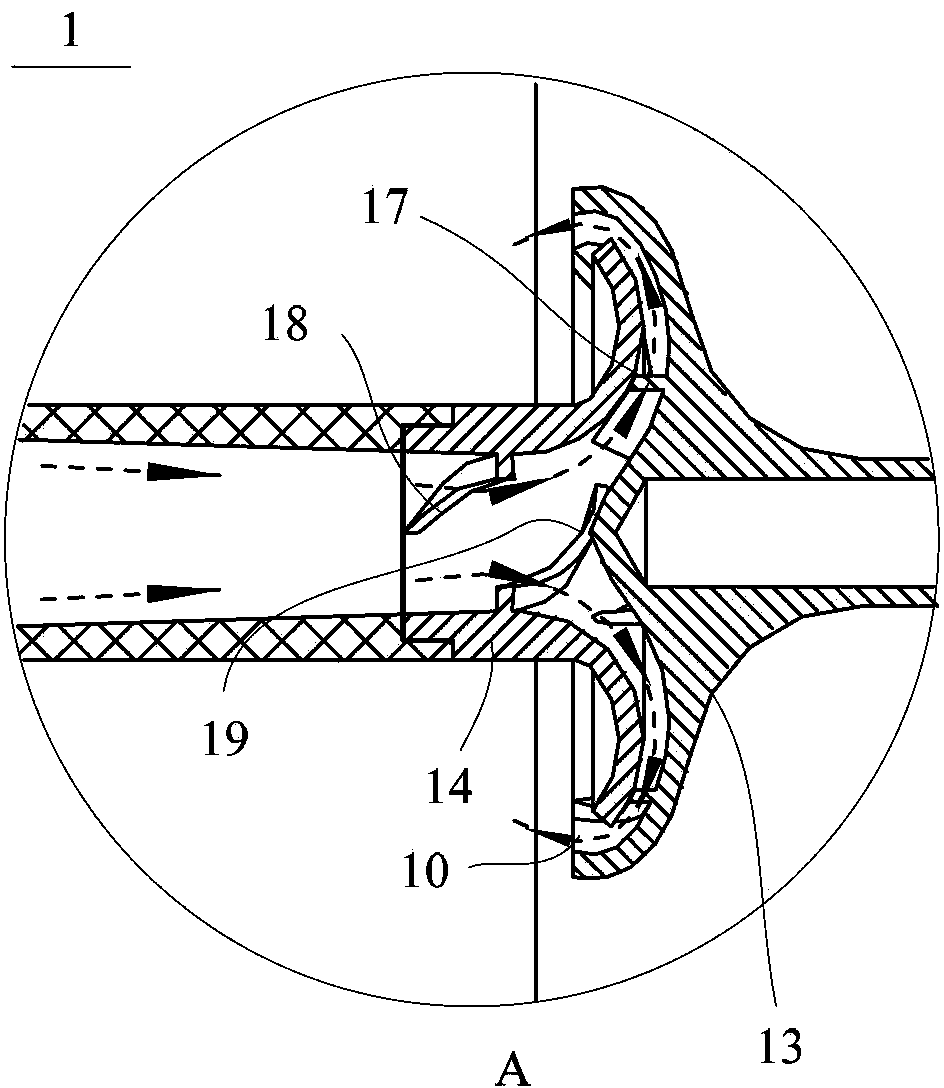

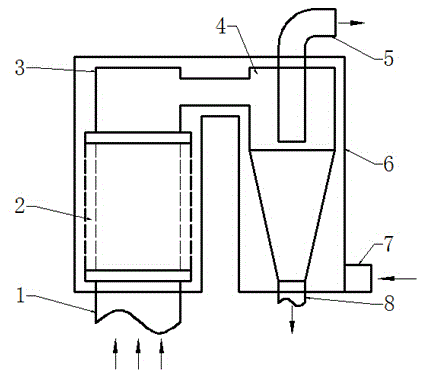

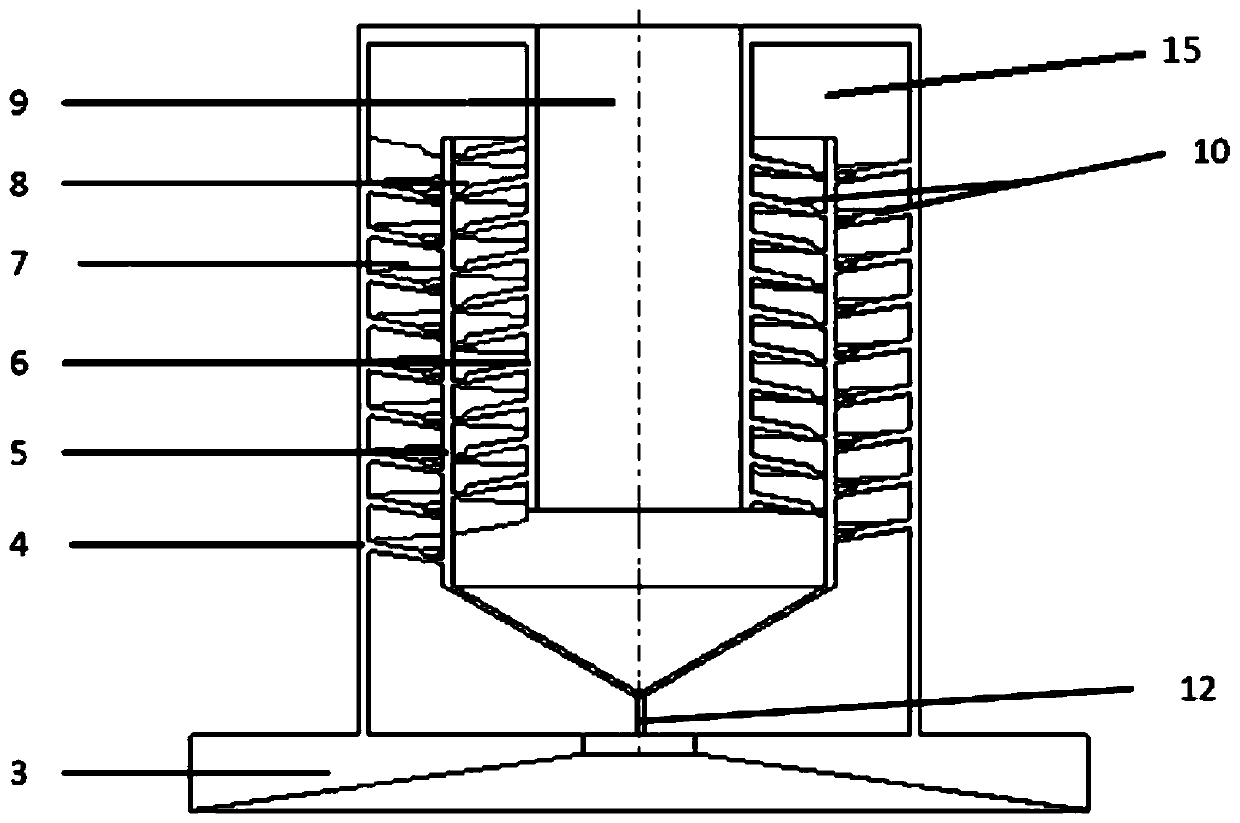

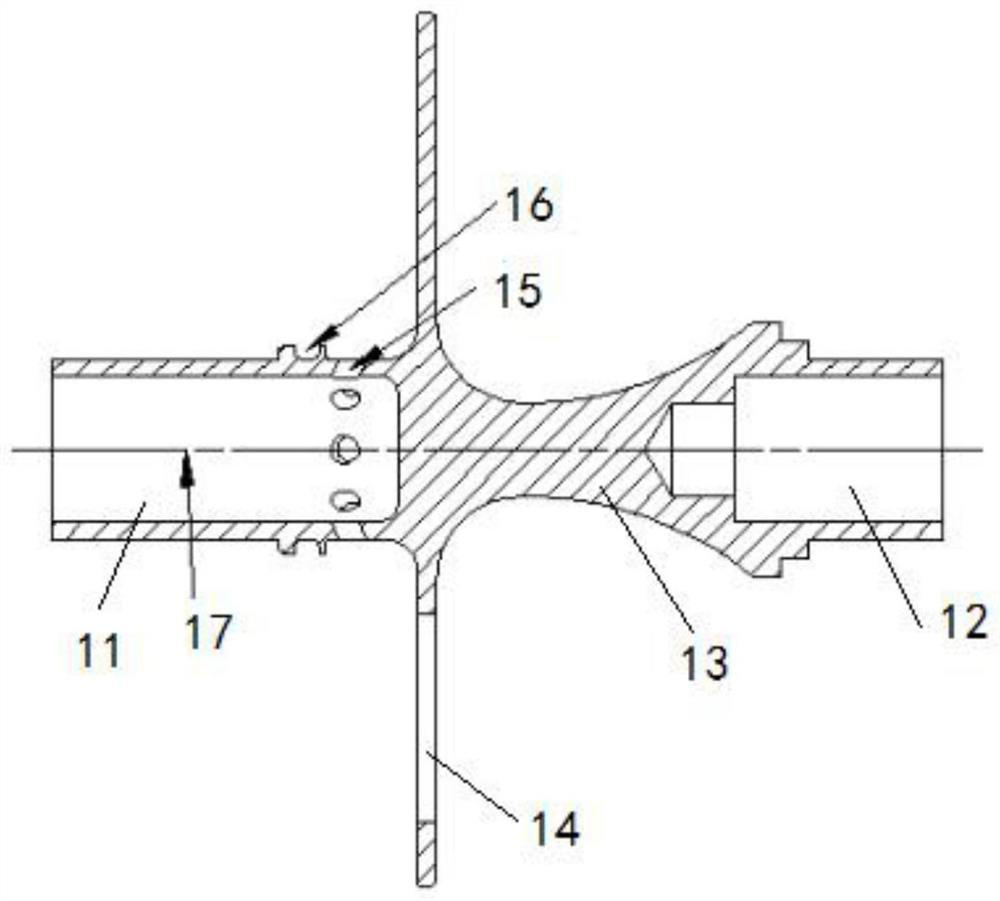

Gas-water separator and cleaning device

ActiveCN104275041AImprove separation efficiencyEasy inflowCombination devicesCarpet cleanersEngineeringSewage

The invention discloses a gas-water separator and a cleaning device. The cleaning device comprises a water suction port (3) and a gas-water separator which are communicated with each other, wherein the gas-water separator comprises a barrel body and a flow deflection part; one end of the barrel body is connected and provided with an air outlet (15), and the other end is provided with an air inlet (16); the flow deflection part is arranged inside the barrel body and provided with a circumferential flow deflection channel; the flow deflection channel is provided with a circumferential water outlet (10); the direction of the circumferential water outlet deviates from the direction of the air outlet; and a water-containing gas flow enters the flow deflection channel through the air inlet and is subjected to gas-water separation, and the separated gas flow is discharged out of the barrel body through the air outlet. The circumferential flow deflection channel arranged in the cleaning device can increase the flow deflection area and enhance the gas-water separation efficiency; and when the cleaning device using the gas-water separator cleans a vertical surface, the cleaning device is not restricted by the direction, and the separated sewage can conveniently flow into the barrel body, thereby enhancing the use flexibility.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

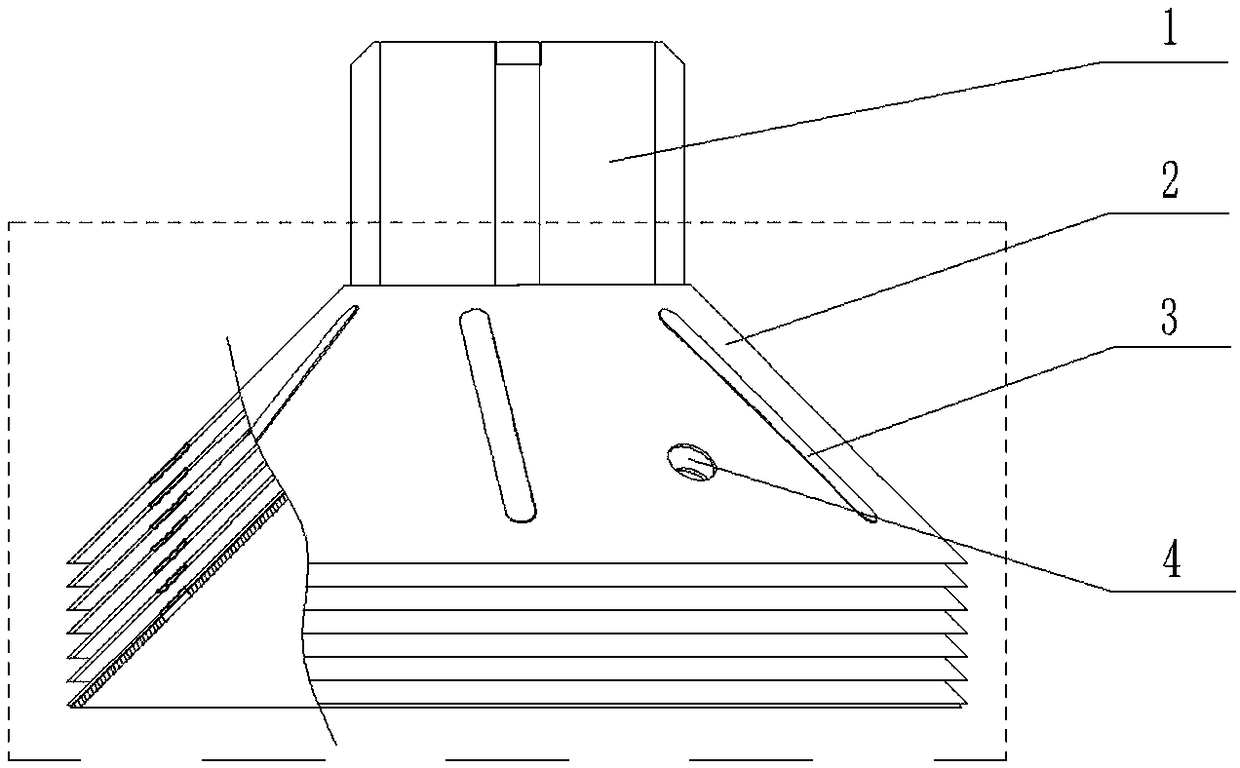

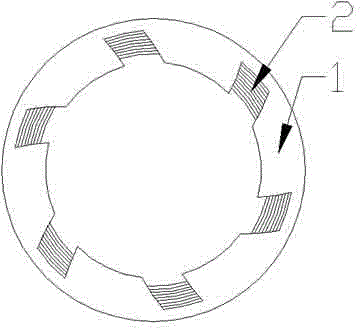

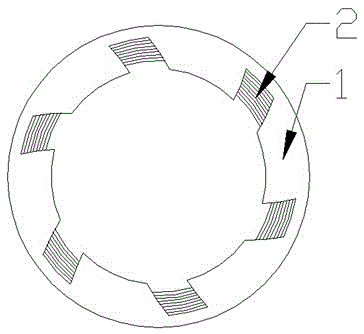

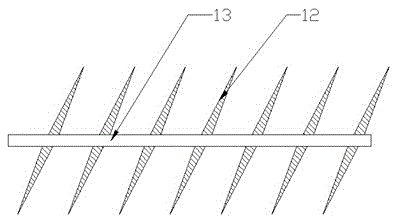

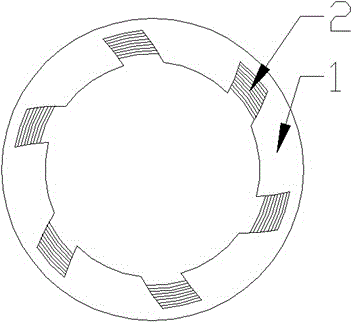

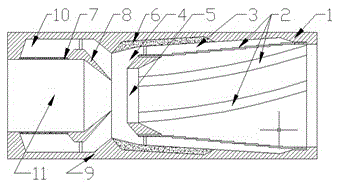

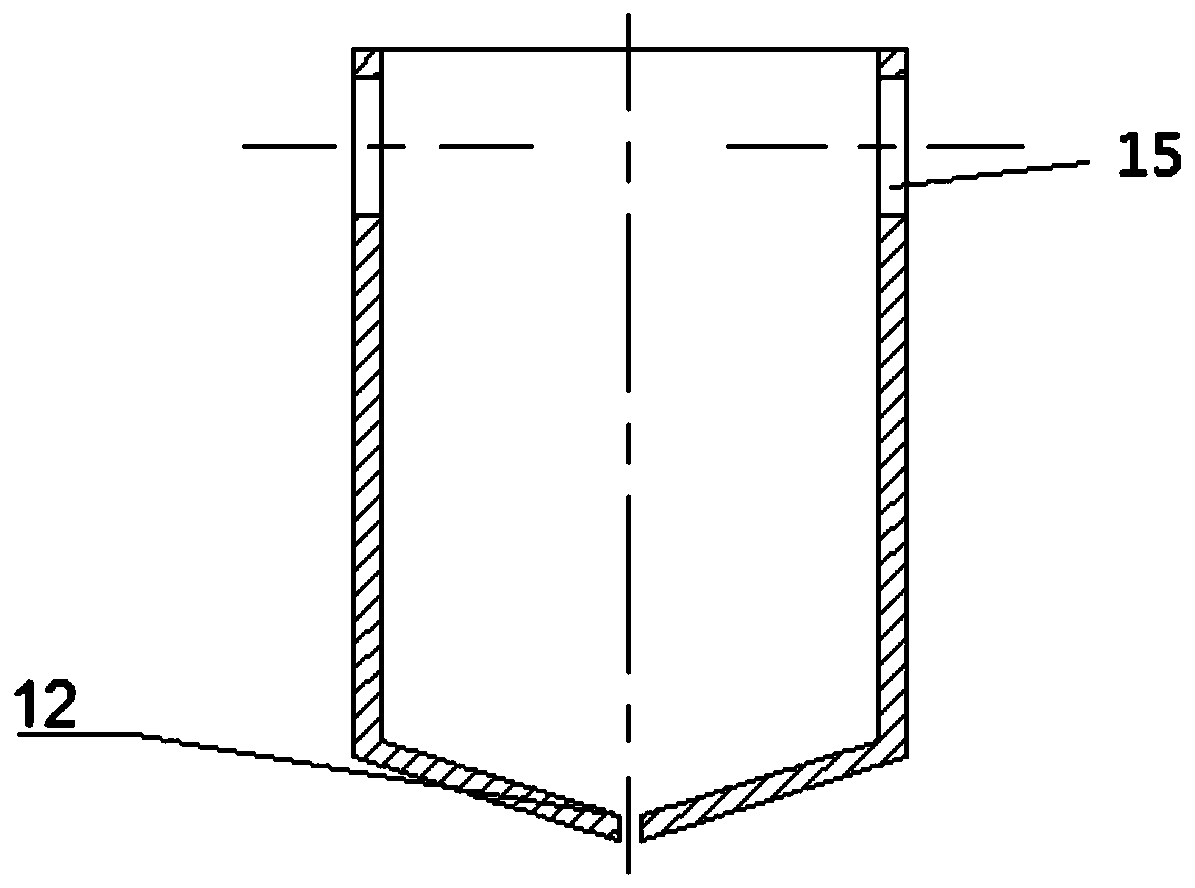

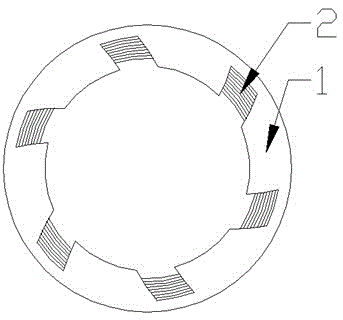

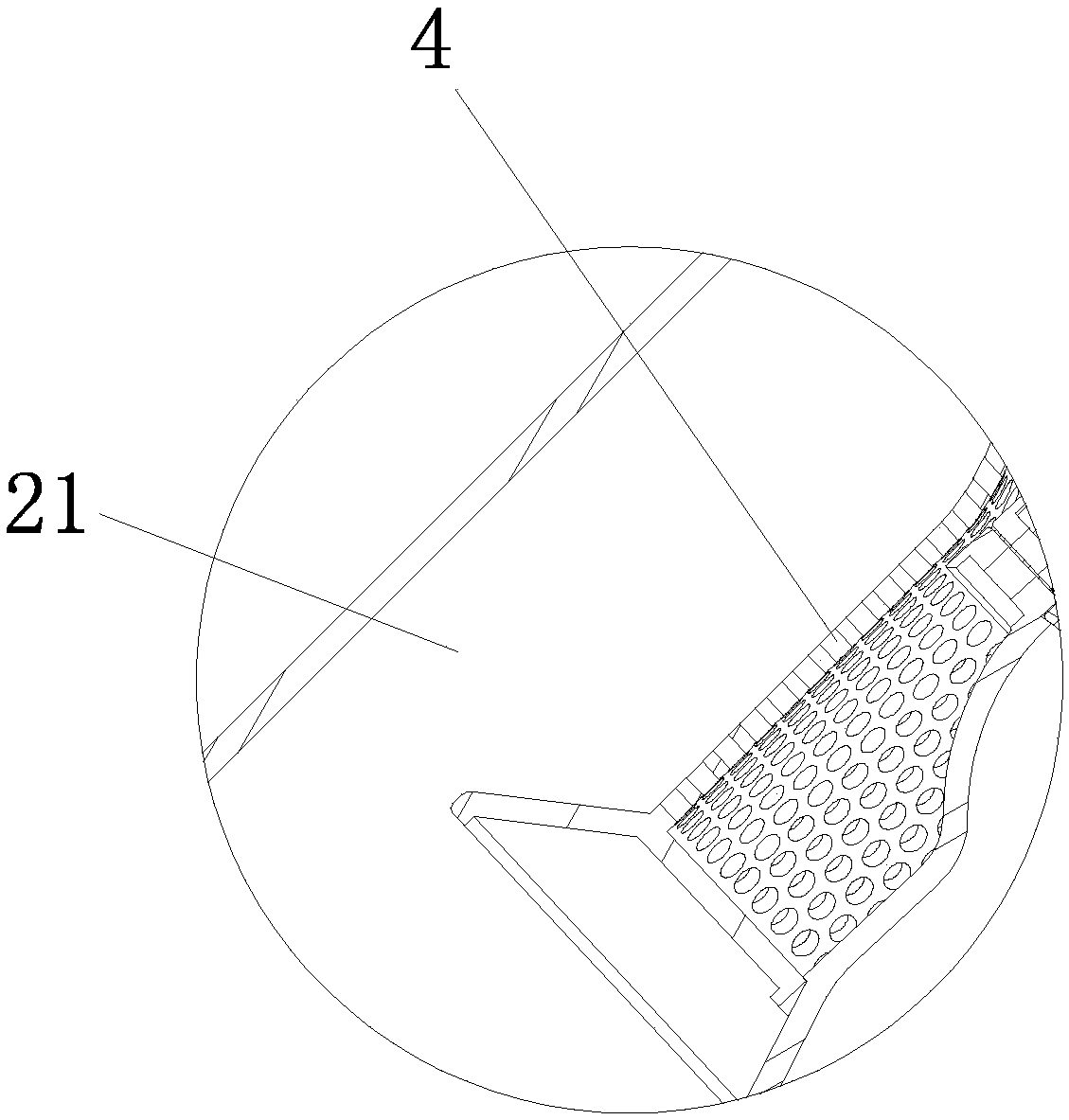

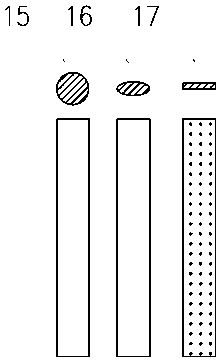

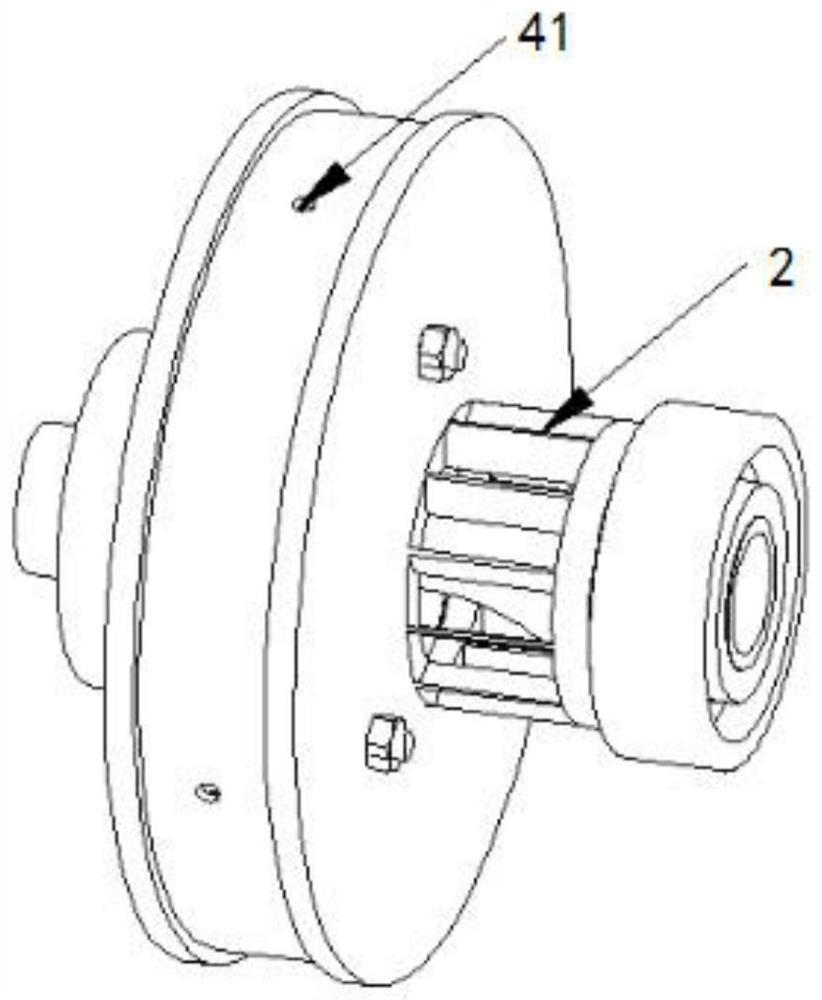

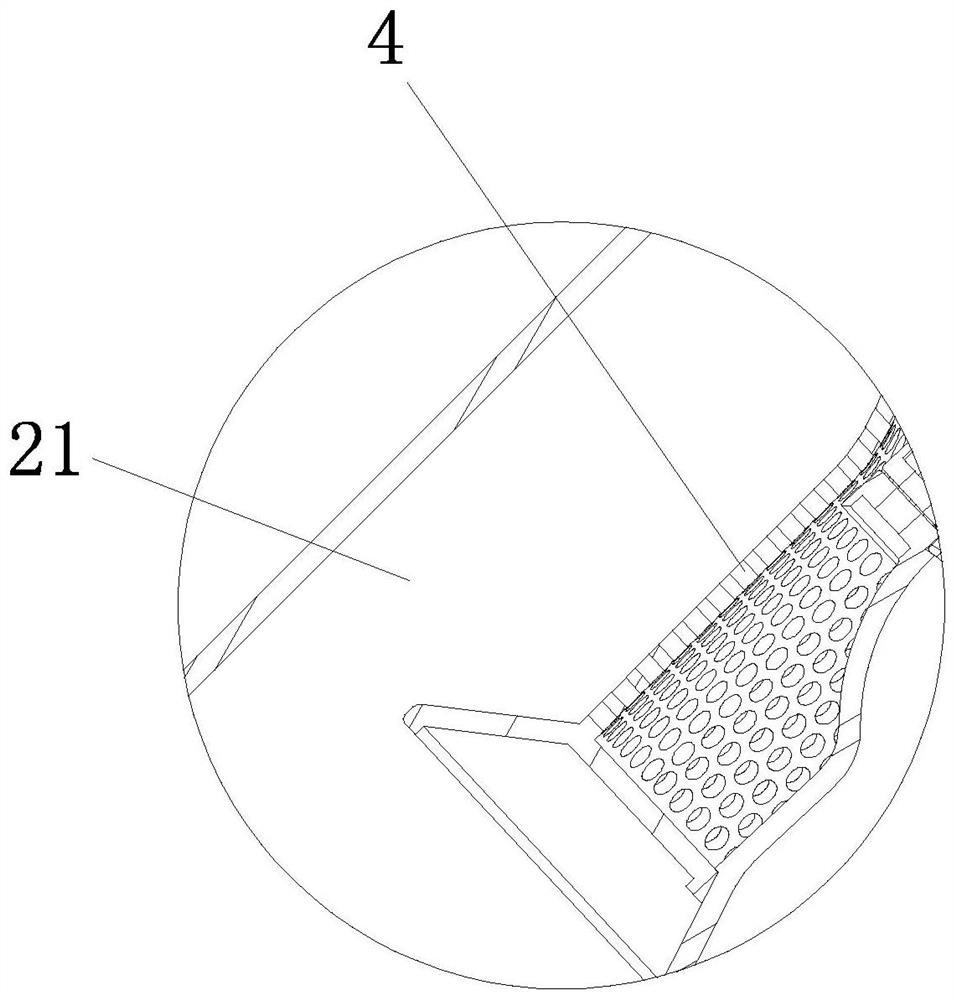

Diverging type neutral hole disc group of disc centrifuge

InactiveCN108246522AImprove uneven distributionImprove the effectCentrifugesMechanical engineeringCentrifuge

The invention discloses a diverging type neutral hole disc group of a disc centrifuge. The diverging type neutral hole disc group of the disc centrifuge comprises a disc group and a disc holder (1), wherein the disc group is composed of a plurality of discs (2). The diverging type neutral hole disc group of the disc centrifuge is characterized in that each disc in the disc group is provided with arib (3) and a feeding neutral hole (4) which gradually increases in size from bottom to top to form a diverging shape. The change of the size of the feeding neutral hole of each single disc is controlled, so that the neutral hole as a whole is a smaller-end-down diverging type, the problem of uneven distribution of the feeding of the separation liquid to be separated in each layer is solved, andthe centrifugal separation effect is improved.

Owner:CHANGZHOU UNIV

Screw type liquid filter

InactiveCN104399312AImprove filtering effectImprove securityFiltration circuitsEngineeringFiltration

A related screw type liquid filter comprises a swirling separation part, a conflux separation part and a spiral inflow pipe; the spiral inflow pipe wraps the outer wall of the swirling separation part; the swirling separation part rotates a fluid mainly through a main body provided with a spiral swirling tank, so that impurities with different mass are separated; and the fluid is subjected to secondary separation filtration in a separation assembly with a gradually divergent opening in the conflux separation part. Therefore, secondary separation is performed on the fluid through a simple structure. The screw type liquid filter is convenient to mount and low in cost.

Owner:WUXI EPIC TECH

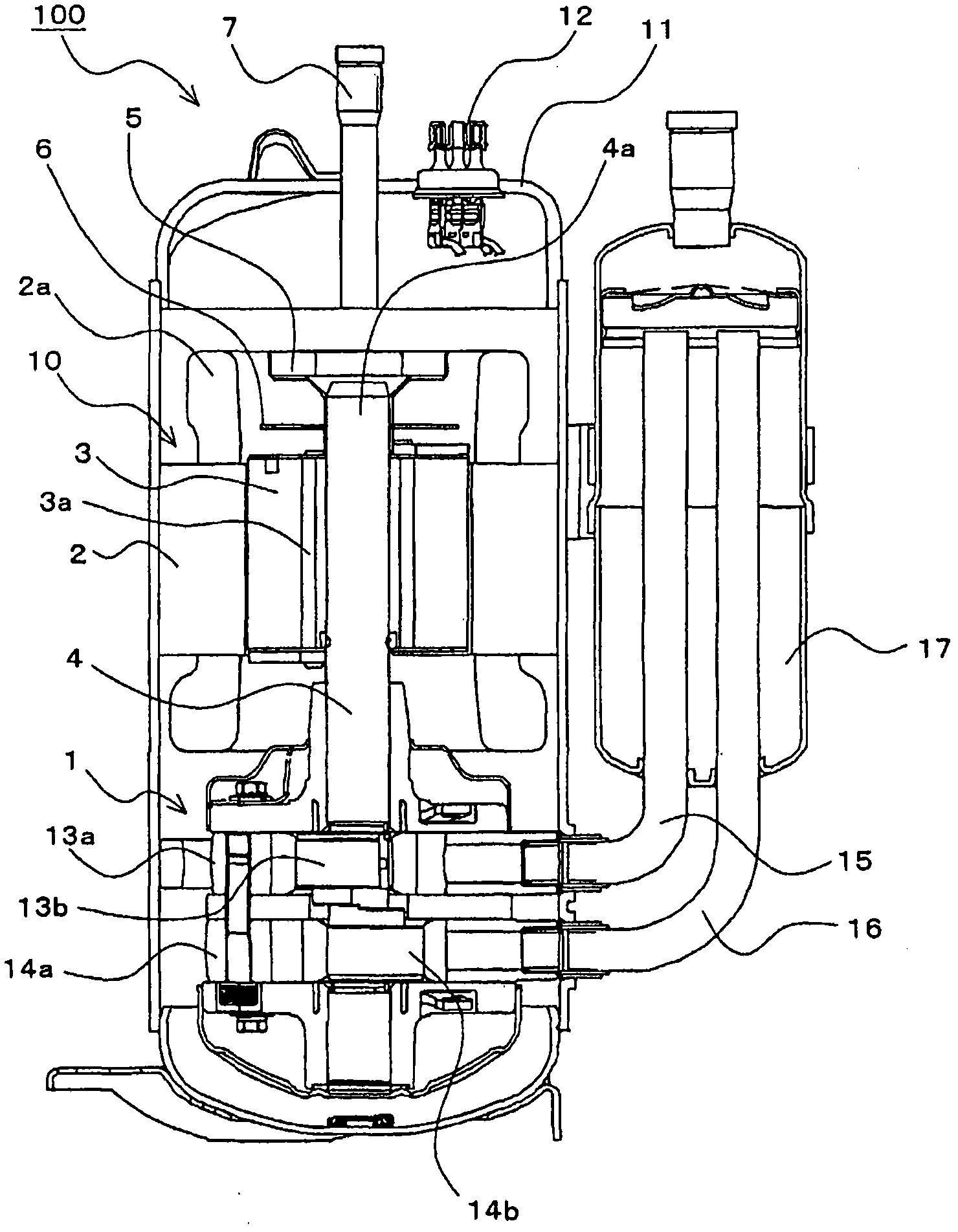

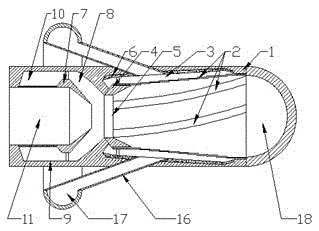

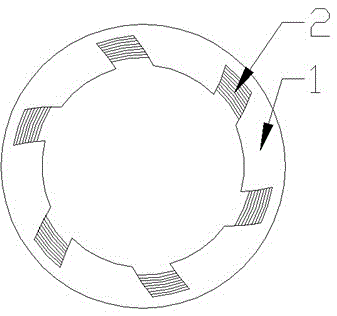

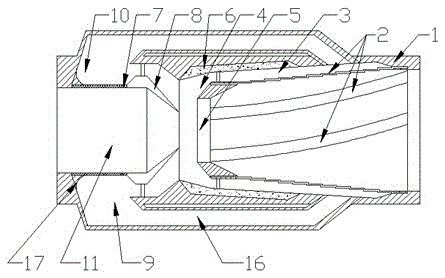

Compressor

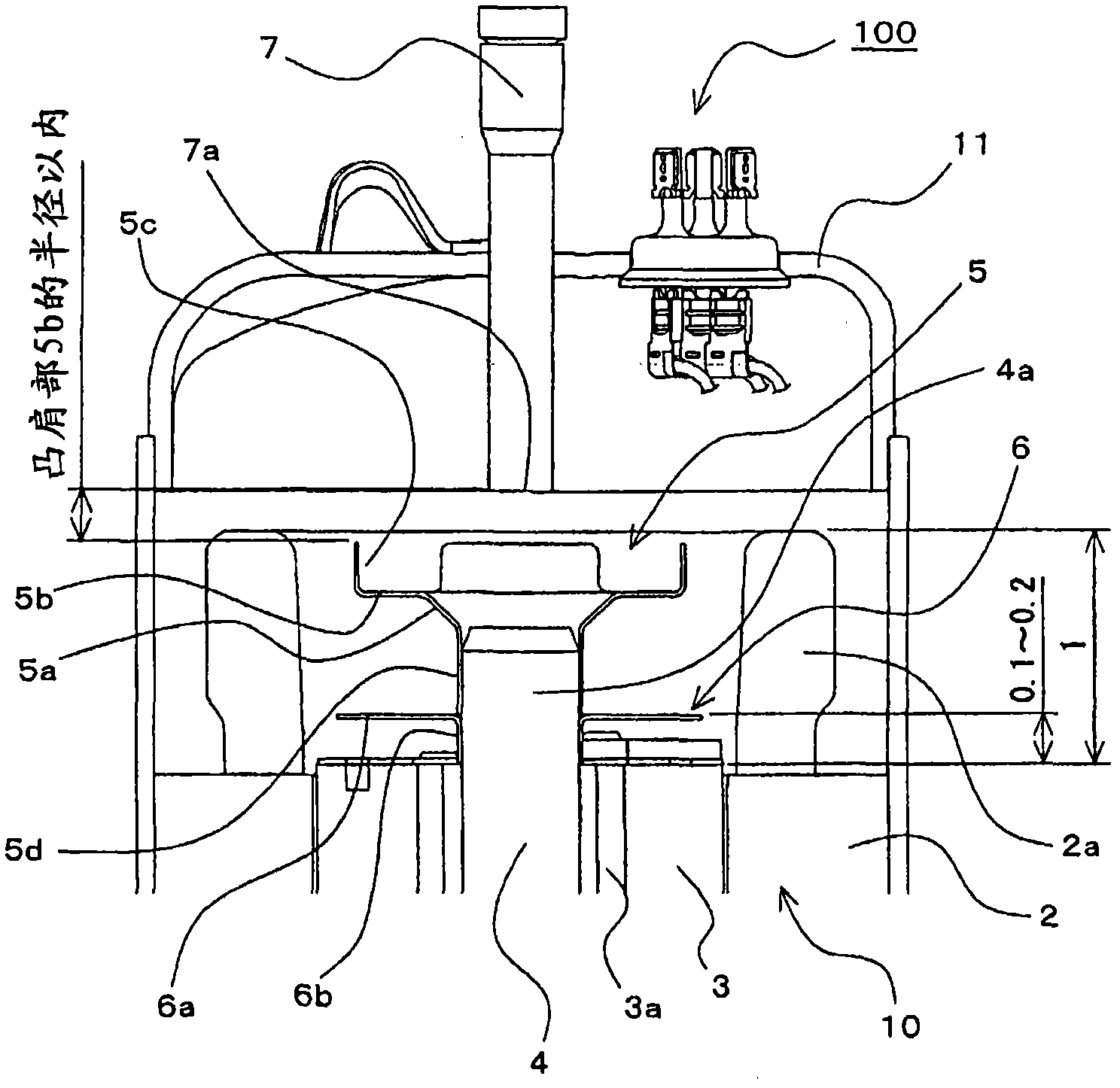

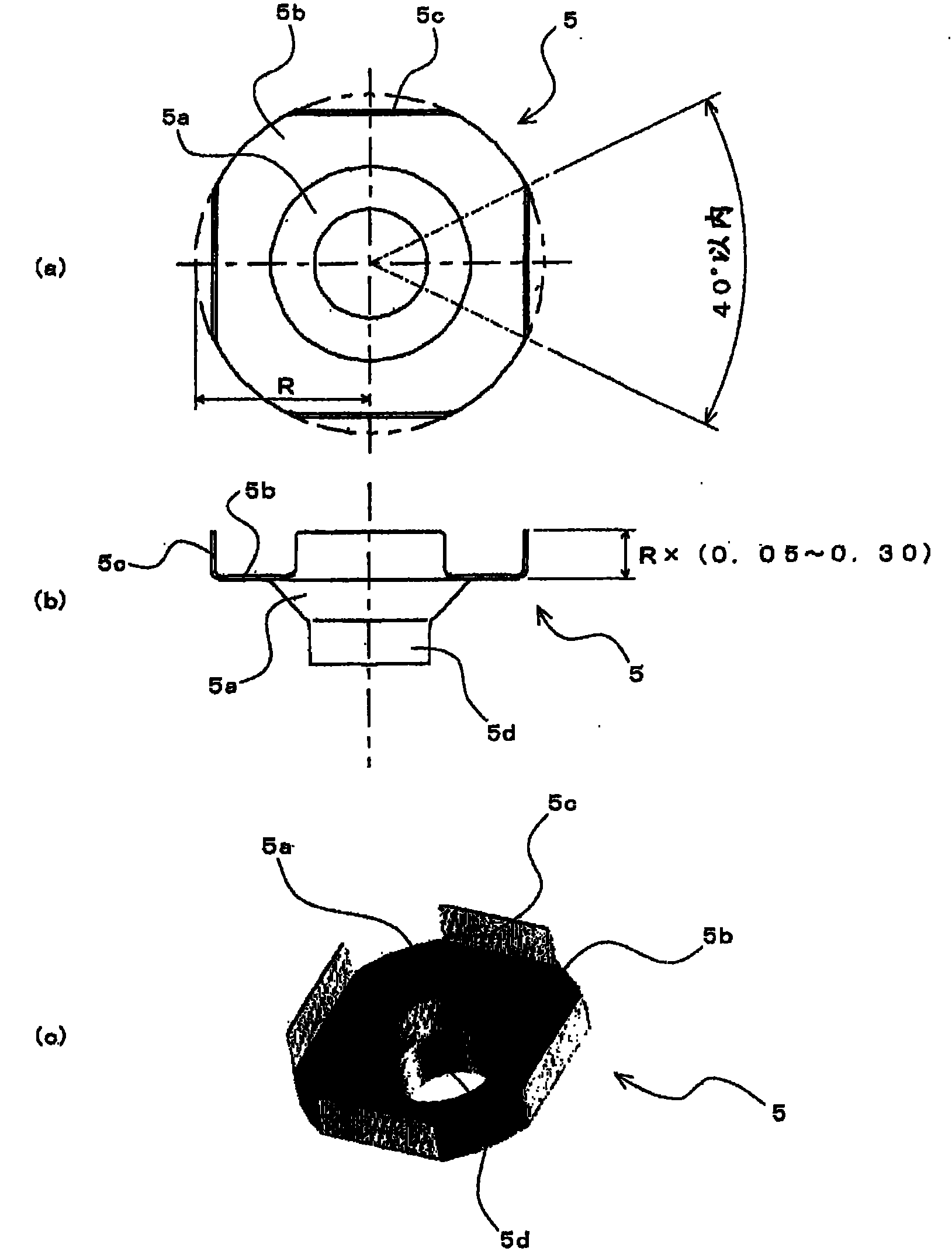

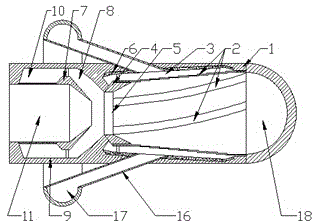

ActiveCN102062080BImprove centrifugal separation effectEasy to separateRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsDrive shaftOil separation

The invention provides a compressor with an oil separation effect better than that of conventional compressors. A first oil separation member (5), disposed on a projecting part (4a) of a driving shaft (4) protruding from the upper part of a rotor (3), has a crossette part (5b) projected in the radius direction of the driving shaft. The crossette part (5b) is composed of annular plate members, and multiple portions of the periphery of the plate members are bended to form bending parts (5c), which have a polygonal shape in the top view.

Owner:MITSUBISHI ELECTRIC CORP

Liquid-gas separation method

InactiveCN107638717AImprove separation efficiencyReduce internal pressureLiquid degasificationInternal pressureImpeller

The invention discloses a liquid-gas separation method. The liquid-gas separation method is characterized by comprising the following steps that: a) gas-containing slurry is sprayed into a rotor of aliquid-gas separator; b) the gas-containing slurry collides with blades in the rotor to carry out primary liquid-gas separation; c) the gas-containing slurry pushes the rotor to rotate to carry out secondary liquid-gas separation; d) the rotor rotates to throw out the gas-containing slurry which is uniformly thrown on the inner wall of a separating hood, the gas-containing slurry flows downwards along the inner wall of the separating hood under the action of gravity to form an extremely-thin drum-shaped liquid film, and gas in the gas-containing slurry escapes from the drum-shaped liquid filmto carry out tertiary liquid-gas separation; e) the rotor rotates to drive the impeller integrated with the rotor to rotate so as to discharge gas in the liquid-gas separator, reduce the internal pressure of the liquid-gas separator and separate liquid and gas. The liquid-gas separation method disclosed by the invention has the advantages that by good matching of the rotor and the impeller, three-time liquid-gas separation can be realized, the gas in the gas-containing slurry can be thoroughly separated. The liquid-gas separation method has the characteristics of high liquid-gas separation efficiency and good separation effect.

Owner:CHENGDU ZHUOXIN IND

electric vacuum cleaner

ActiveCN105816101BImprove centrifugal separation effectShorten the upper and lower lengthSuction filtersEngineeringGuide tube

The invention provides an electric dust collector usable in both a rod type and a portable type. The electric dust collector has a whirlwind dust collection device capable of maintaining an absorption force, has a dust centrifugal separation function, is miniature and light, and is convenient to use. The electric dust collector has a dust collector main body. The dust collector main body has an electric fan, an absorption port and the dust collection device. The dust collection device is provided with a basically cylinderical outer cylinder, and an inner cylinder arranged in the basically cylinderical outer cylinder. The inner cylinder and the outer cylinder are roughly configured in a concentric manner. The outer cylinder is provided with an inflow port at the side part. The inflow port is communicated with one end of a guiding tube. The guiding tube is arranged in the dust collector main body and are open on two ends. The absorption port is arranged on the other end of the guiding tube. The guiding tube is arranged on the side part of the dust collection device. The absorption is arranged between the guiding tube and the dust collection device.

Owner:HITACHI APPLIANCES INC

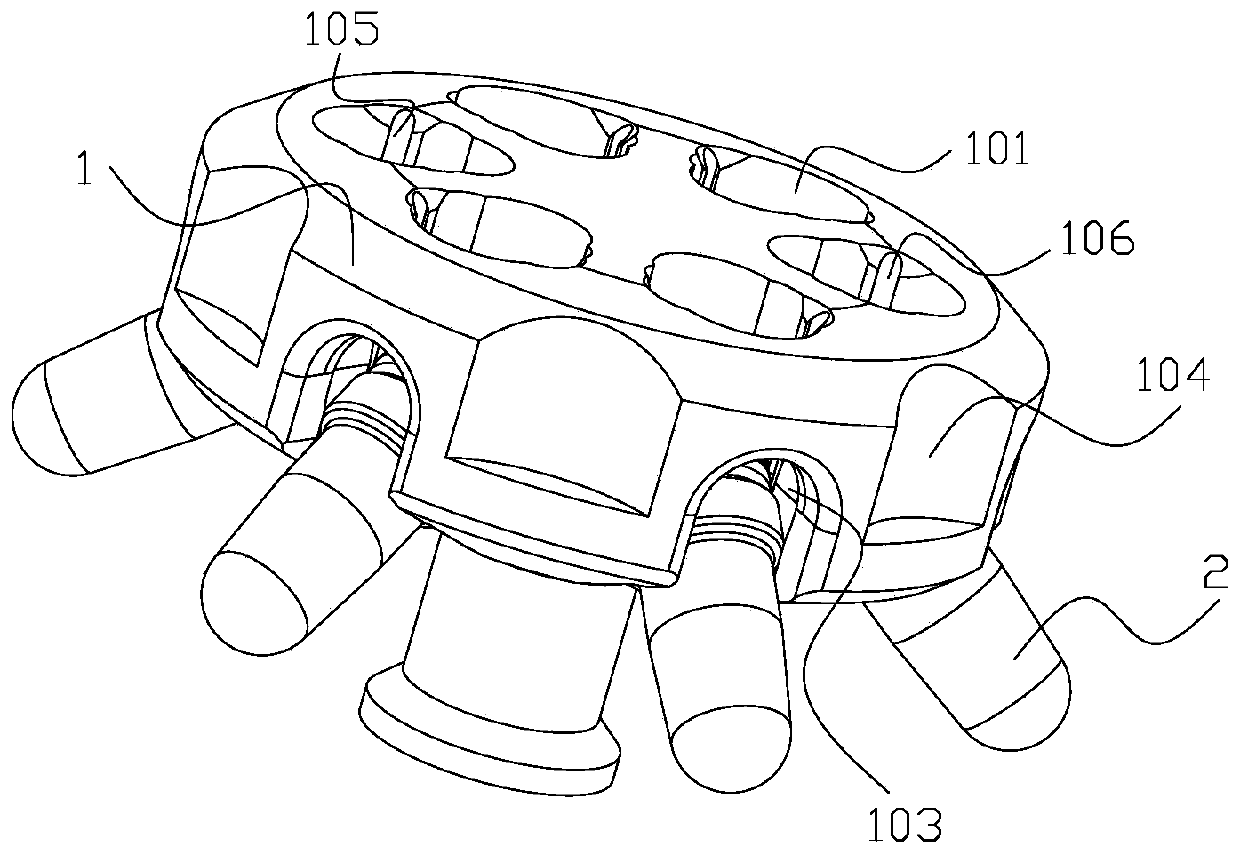

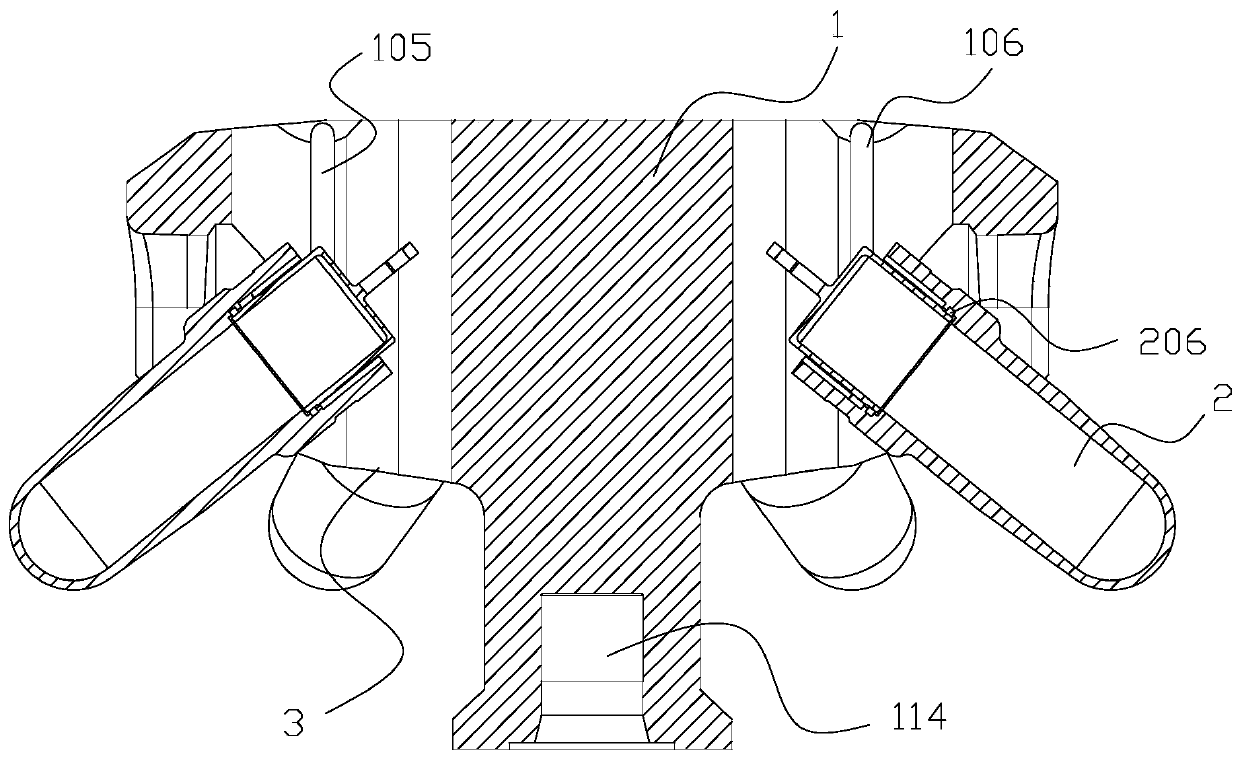

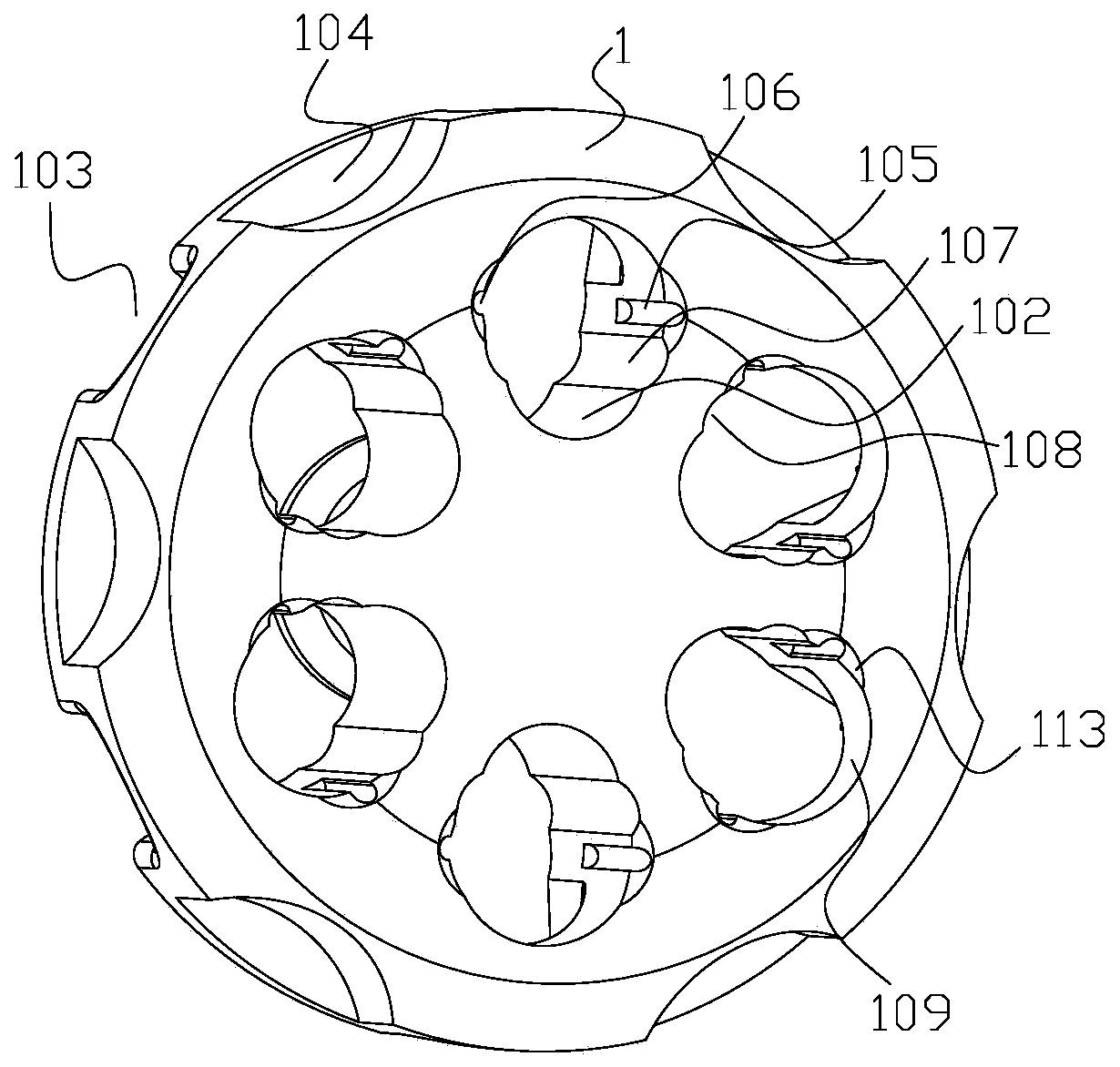

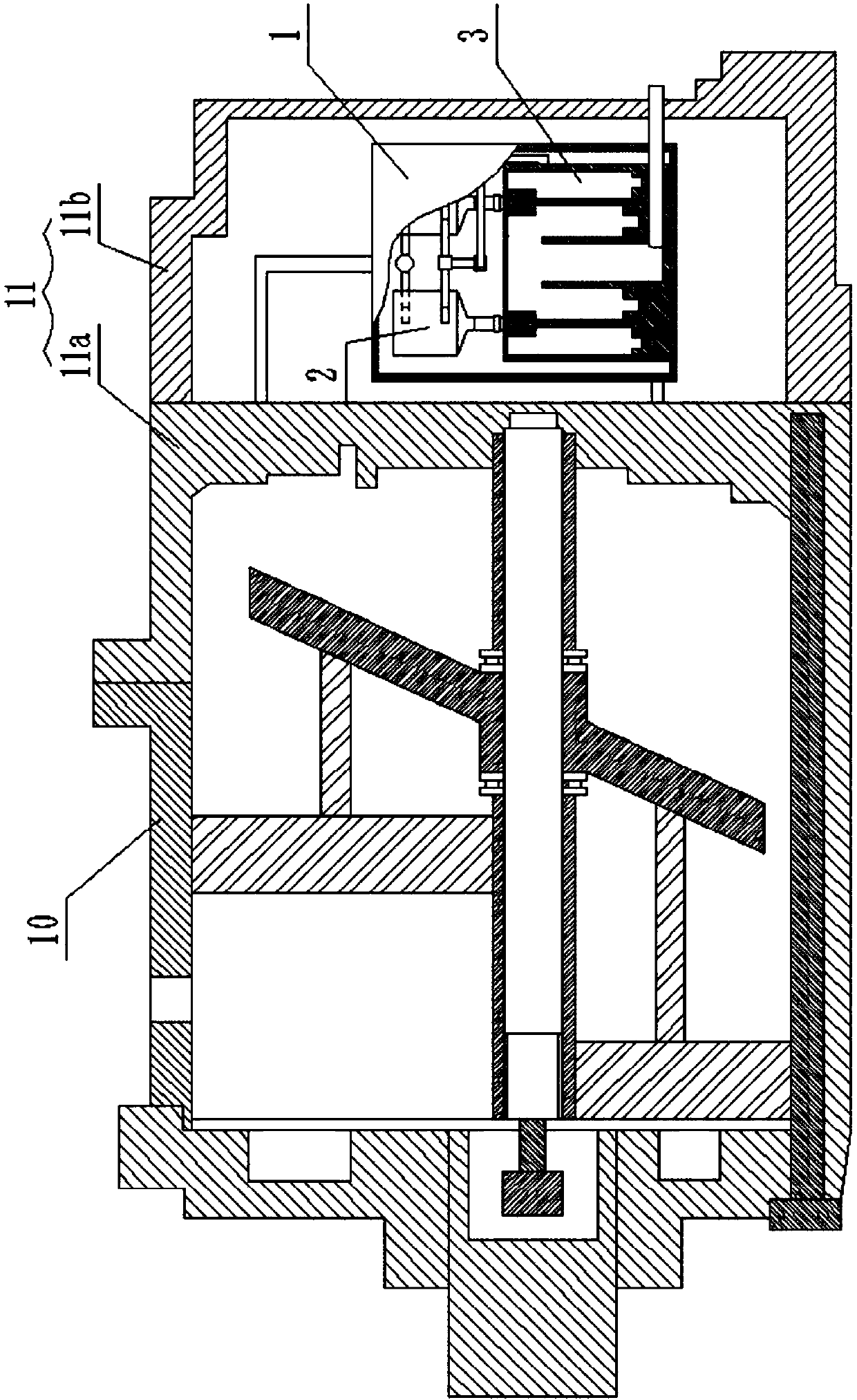

Medical high-speed centrifuging equipment and centrifugal rotor

InactiveCN109821665AEasy to assemble and disassembleEasy to sampleCentrifugesEngineeringCentrifugal force

The invention relates to the technical field of medical detection, in particular to medical high-speed centrifuging equipment and a centrifugal rotor. According to the medical high-speed centrifugal rotor, the rotor comprises a centrifugal rotation frame and hanging cups. A plurality of hanging cup grooves are formed in the top face of the centrifugal rotation frame in an array manner, and each hanging cup groove is provided with a matched sliding groove. The positions, corresponding to the hanging cup grooves, on the side wall of the upper portion of the centrifugal rotation frame are provided with U-shaped grooves in an array manner, and openings of the U-shaped grooves are arranged downwards. Each hanging cup comprises a hanging cup pipe and a hanging cup matched connector arranged on the hanging cup pipe, wherein a matched protruding block is arranged at the outer portion of the hanging cup matched connector, and the matched protruding block is matched with the corresponding matched sliding groove and arranged on the centrifugal rotation frame. The medical high-speed centrifuging equipment and the centrifugal rotor have the beneficial effects that hanging cup dismounting and mounting can be convenient, and sampling can be conveniently conducted on multiple sample reagents; all particles in liquid can be prevented from being deposited on the side walls of the hanging cup pipes, and the sampling efficiency and the sampling data accuracy are improved; and the hanging cups are prevented from being in a completely vertical or completely horizontal state, and the centrifugalseparation effect is improved.

Owner:王加皮

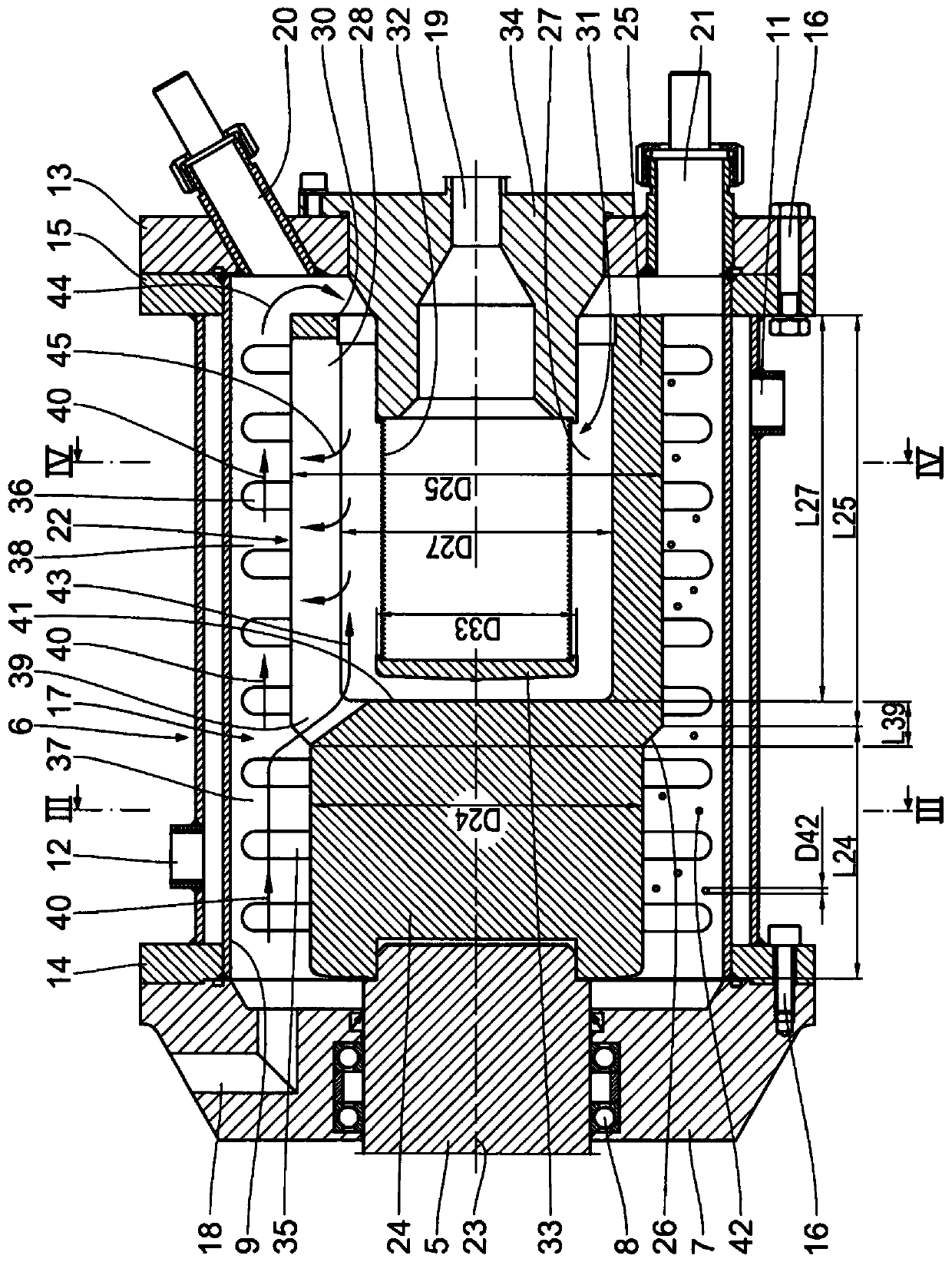

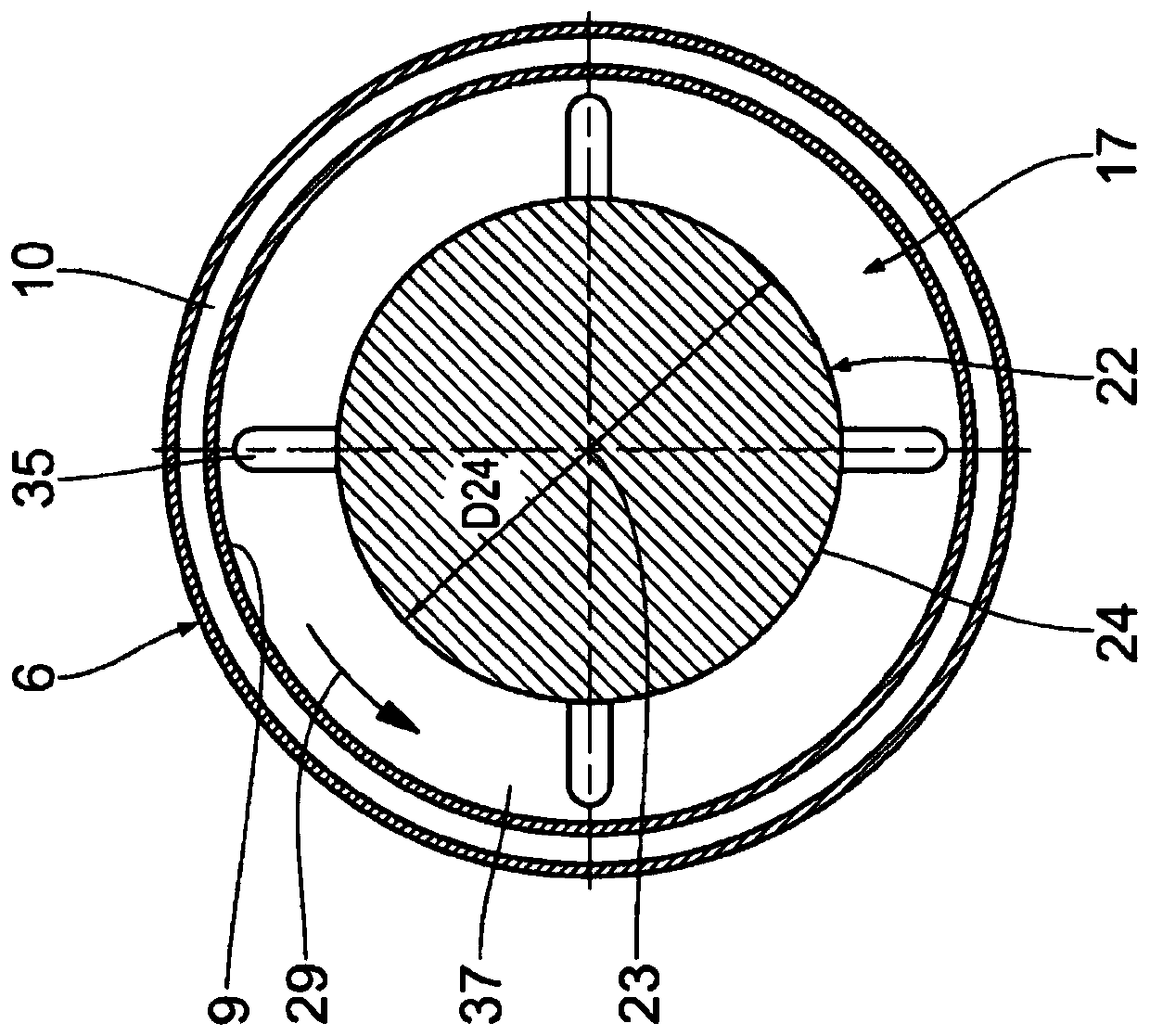

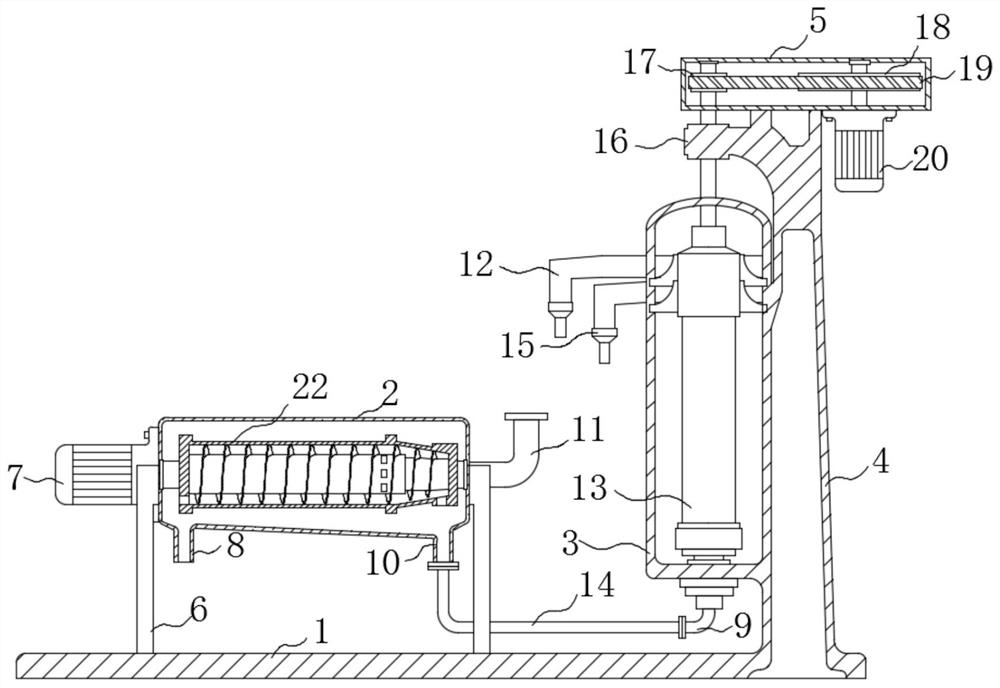

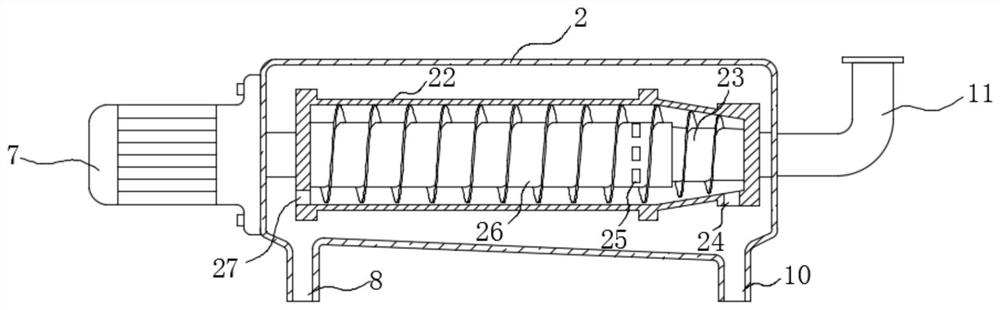

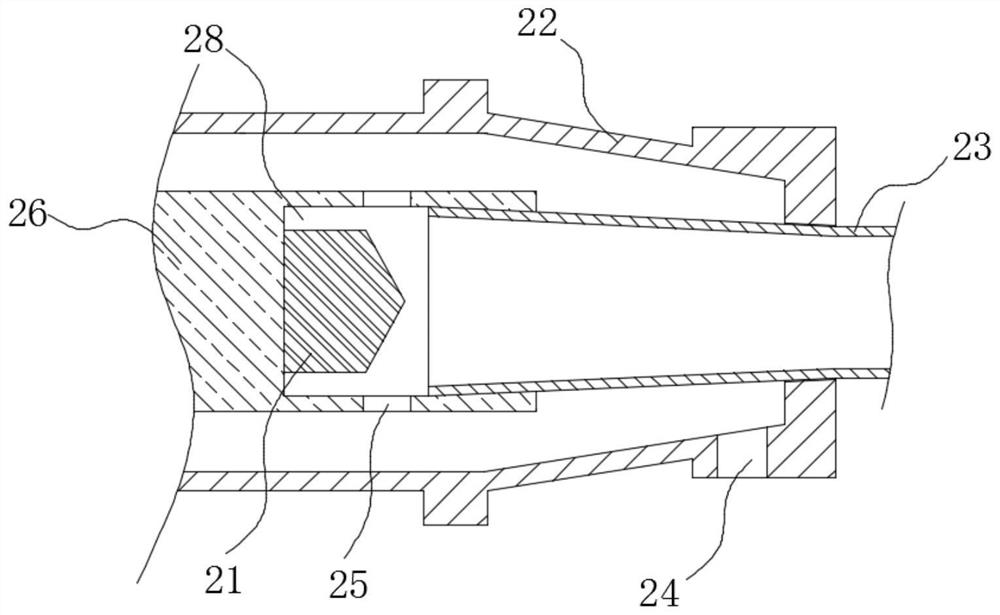

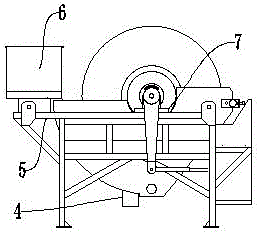

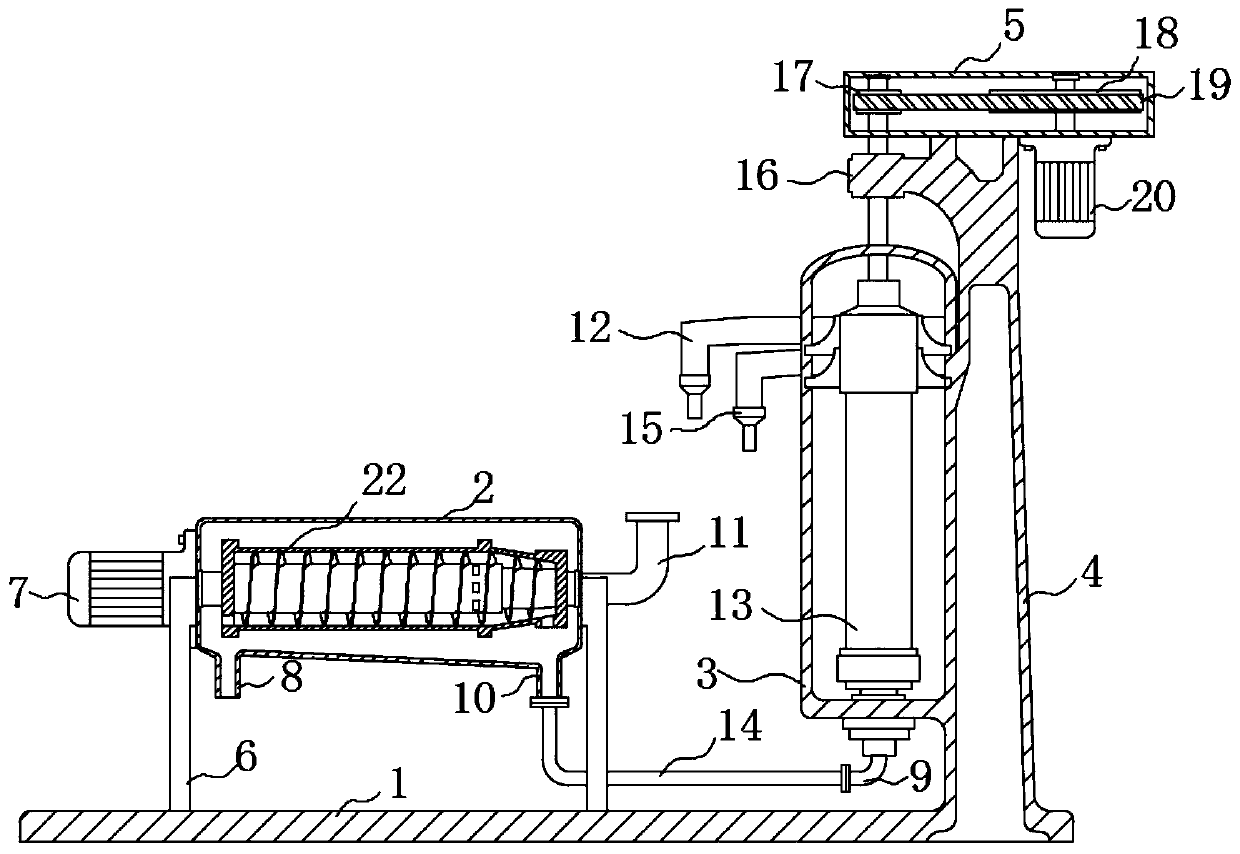

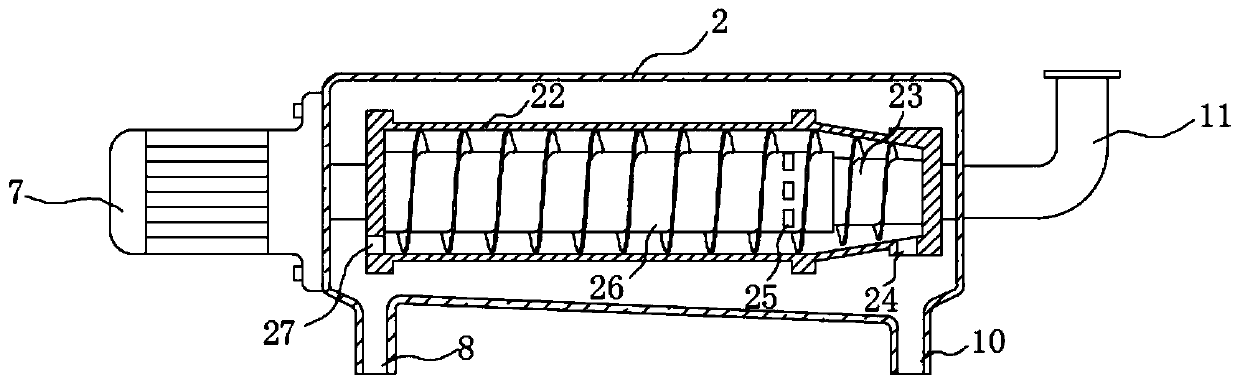

Stirring mill

ActiveCN110198787AGood effectImprove centrifugal separation effectRotary stirring mixersTransportation and packagingThermodynamicsEngineering

The invention relates to a stirring mill. The stirring mill comprises a horizontally arranged milling vessel (6) and a stirring shaft (22) which is arranged therein so that it can be rotationally driven. The stirring shaft (22) has a first stirring shaft section (24) adjacent to an inlet for material to be ground (18), which has a smaller diameter D24, and a second stirring shaft section (25) adjacent to an outlet for material to be ground (19), which has a larger diameter D25 and in which a separating device (31) is formed. Bypass channels (39') leading into the separating device (31) are formed in the first stirring shaft section (24).

Owner:耐驰精细研磨技术有限公司

Oil-gas separator for vehicle-mounted air conditioner compressor and vehicle-mounted air conditioner compressor

PendingCN107747833AAchieve primary separationImprove separation efficiencyRefrigeration componentsIn vehicleMechanical engineering

The present invention discloses an oil-gas separator for a vehicle-mounted air conditioner compressor. The oil-gas separator comprises a shell, a centrifugal separation device and a secondary separation filter cartridge are disposed in the shell from top to bottom and connected via pipelines, and the shell is respectively communicated with the centrifugal separation device and the secondary separation filter cartridge to form an oil gas channel, an exhaust channel and an oil draining channel. Compared with the prior art, the oil-gas separator for a vehicle-mounted air conditioner compressor and the vehicle-mounted air conditioner compressor are reasonable in design and simple in structure, centrifugal type separation is adopted to achieve preliminary separation so as to reduce the oil content of mixed gas at a filter screen, and normal use and filtering efficiency of the secondary separation filter cartridge are ensured; and filter screen type separation is adopted to achieve secondaryseparation to separate lubricating oil from the mixed gas, separation efficiency is high, the proportion of the lubricating oil of an auto air-conditioner compressor participating a refrigerant cycleis reduced, compressor efficiency of the auto air-conditioner compressor is improved, and heat exchange efficiency of a condenser and an evaporator is improved.

Owner:江苏成科新能源有限公司

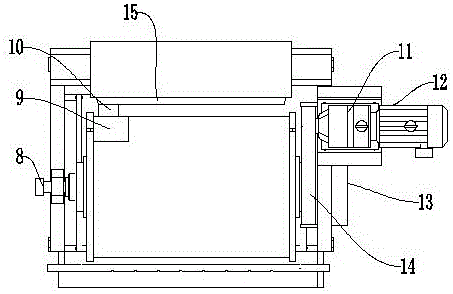

A kind of oxidized polyethylene separation tower and separation method thereof

ActiveCN109999538BAchieve separationImport uniformLiquid separationFiltration circuitsEngineeringMaterial transfer

The invention discloses an oxidized polyethylene separation tower. The oxidized polyethylene separation tower comprises a base, wherein a solid-liquid separation mechanism and a liquid-liquid separation mechanism are mounted on the upper end surface of the base and are communicated through a connecting pipe; a feeding pipe is communicated with the solid-liquid separation mechanism; a light liquiddischarging pipe and a heavy liquid discharging pipe are communicated with the liquid-liquid separation mechanism; a drive mechanism and a transmission mechanism are mounted at the upper end of the liquid-liquid separation mechanism. The invention further discloses an oxidized polyethylene separation method. The method comprises following steps: S1, filtering; S2, screening; S3, solid-liquid separation; S4, liquid-liquid separation; S5, repeating of operation. The structure is ingenious, the solid-liquid separation mechanism and the liquid-liquid separation are combined, separation of smaller-particle waxy semi-solids and waxy solids and separation of white viscous oxidized polyethylene with different molecular weights are realized, separation speed of oxidized polyethylene is increased, and loss in a material transfer process is reduced.

Owner:NANJING YANGZI FINE CHEM

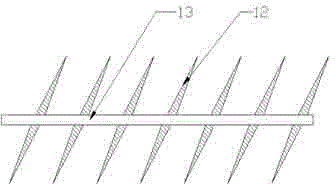

Secondary chlorine gas injection device for fine-particle titanium raw material boiling chlorination furnace

InactiveCN104891561AEnhanced rotational shear interactionsImprove centrifugal separation effectTitanium halidesTitaniumInverted u

The invention discloses a secondary chlorine gas injection device for a fine-particle titanium raw material boiling chlorination furnace. The secondary chlorine gas injection device comprises a boiling chlorination reactor main section, a secondary chlorine gas injection section, a furnace top, a secondary chlorine gas introducing hole, an inverted U-shaped tube shell and a cyclone separator. The cyclone separator is used for separating solid powder and gaseous TiCl4; an ascending tube is arranged in the middle of the cyclone separator, and the lower part of the cyclone separator is communicated with a circulating return leg. The secondary chlorine gas injection section, an outlet of the furnace top, the cyclone separator and the circulating return leg are communicated in sequence, and an inverted U-shaped pipeline is formed at the furnace top. The inverted U-shaped tube shell is arranged outside the inverted U-shaped pipeline and forms a sealed secondary chlorine gas injection channel together with the inverted U-shaped pipeline. The mutual effect of rotational shear of gas and solids at the upper part of the boiling chlorination furnace and the centrifugal separation effect are enhanced, so that the escaped fine particles which not completely react are reduced; and meanwhile, the chlorination reaction efficiency and the yield of TiCl4 are increased, and the temperature of the TiCl4 gas at the top of the boiling chlorination furnace is balanced.

Owner:CHONGQING UNIV

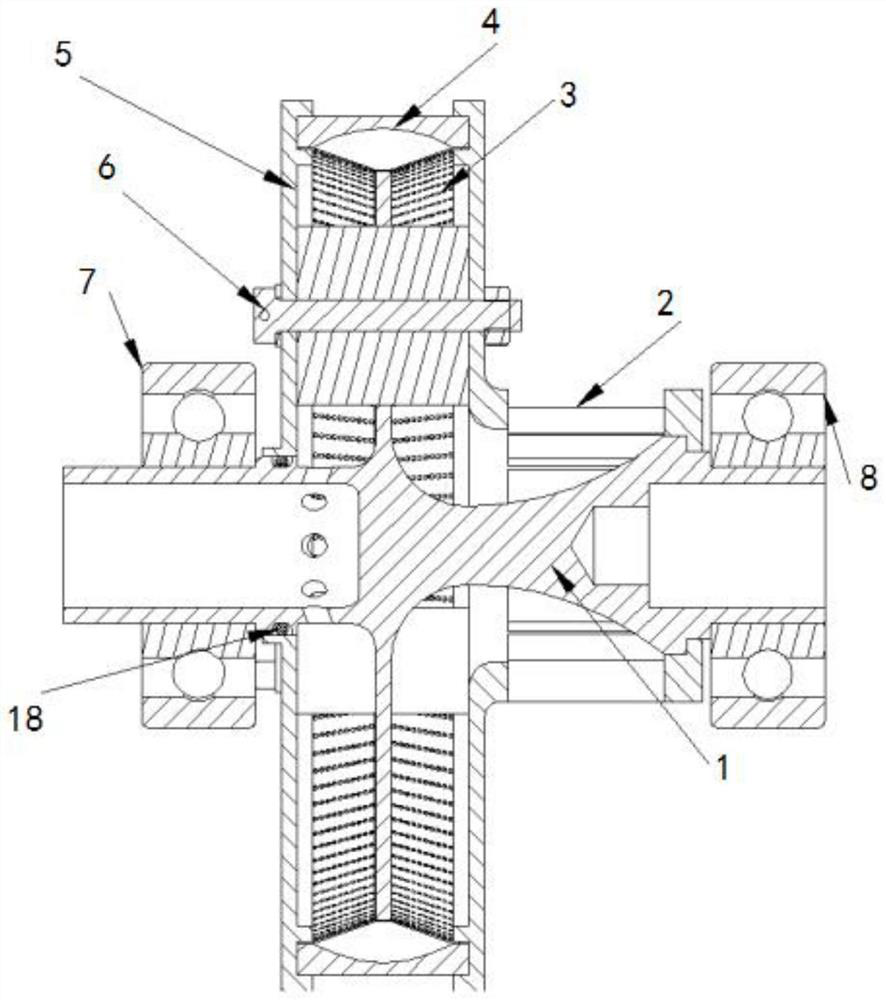

A return type filter joint

The invention relates to a refluxing type filter connector. The refluxing type filter connector comprises a cyclone separating part and a confluxing separating part, wherein the cyclone separating part mainly comprises a connecting mechanism for injecting fluid into the cyclone separating part, the flow-in fluid is subjected to refluxing by one refluxing mechanism after being filtered primarily, the fluid is subjected to rotating by a main body with a spiral cyclone groove, impurities with different masses are separated, then the fluid is subjected to secondary separation and filtration by a gradually-flared separation component in the confluxing separating part, then the fluid is subjected to third separation by a simple structure, the installation is convenient and the manufacture cost is low.

Owner:CHONGQING WEST LINE TECH

A kind of preparation method of high-purity citrus peel essential oil

The invention discloses a preparation method of a high-purity citrus peel essential oil. The method comprises selecting fresh citrus peel as the raw material, cutting the citrus peel into pieces at room temperature, and then soaking the citrus peel pieces into soaking fluid; taking the soaked citrus peel out of the soaking fluid and draining off liquid; squeezing the soaked citrus peel through a screw type squeezer obtain an oil-water mixture containing pigments, pectin and citrus scraps; centrifugally separating the oil-water mixture through a centrifugal separator, extracting an upper oil layer, and filtering the upper oil layer after wexes settle to obtain coarse citrus peel essential oil; refining the coarse citrus peel essential oil through a molecular distillation stepwise method, and collecting distillation residues II which are mainly composed of D-limonene and gamma-terpinolene. By means of the squeezing method and the molecular distillation technology, the preparation method of the high-purity citrus peel essential oil can effective protect thermosensitive components in the essential oil and produce the citrus peel essential oil, which is clear in color, pure and rich in fragrance and prominent in characteristic flavor, under the condition of low temperature and no organic solvent.

Owner:广州爱伯馨香料有限公司

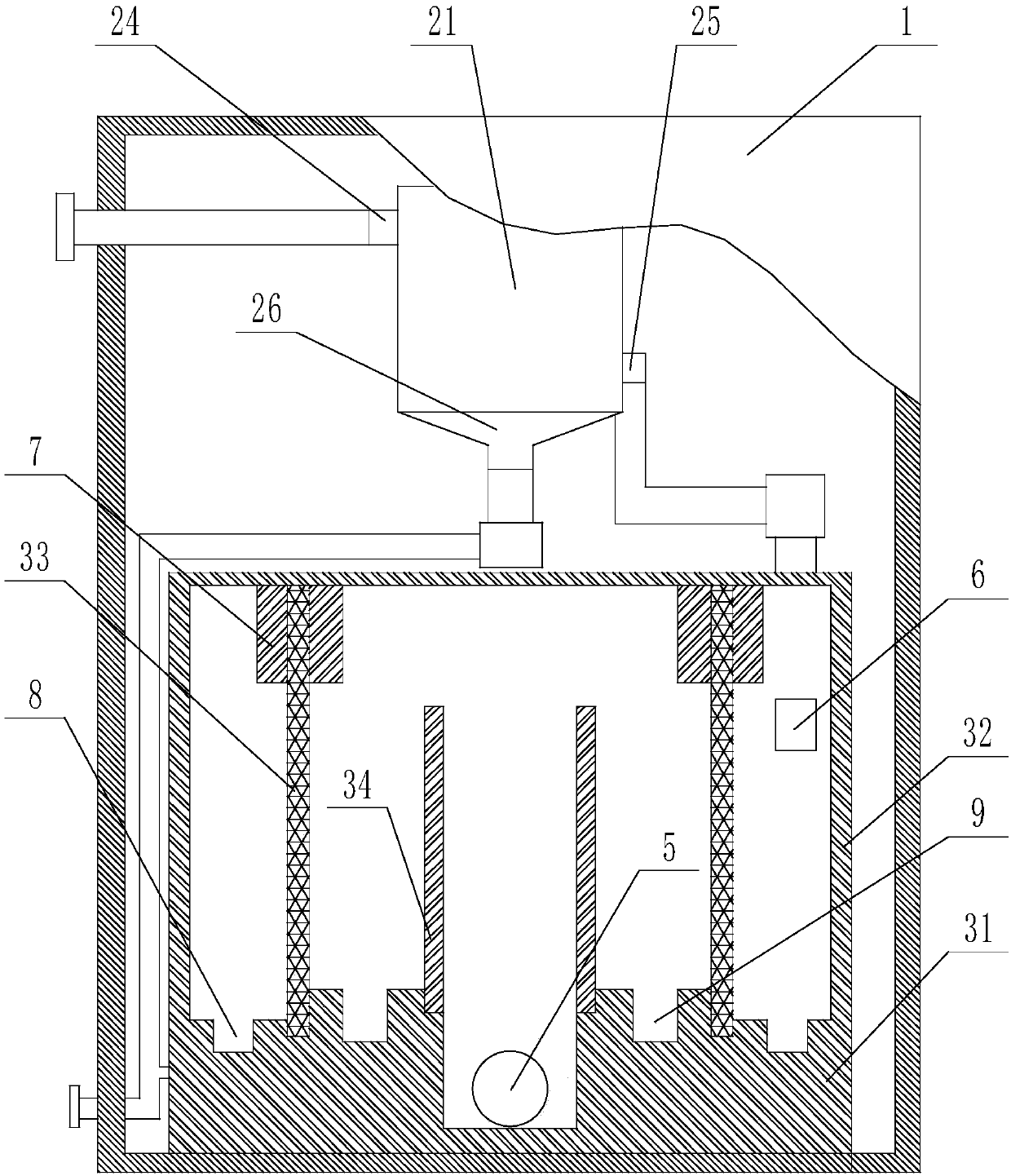

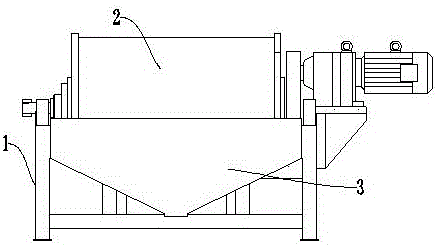

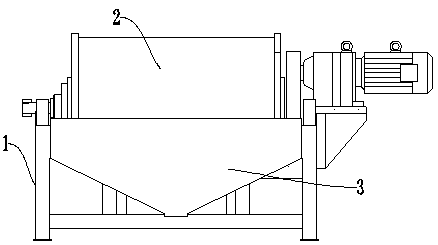

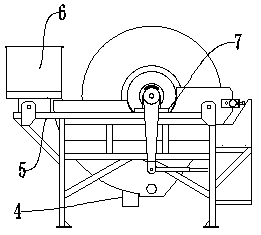

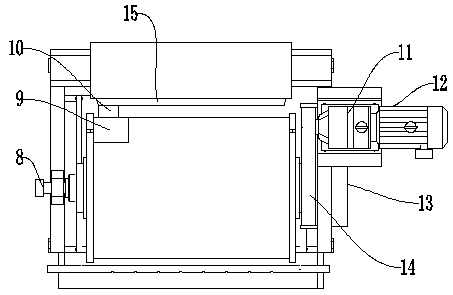

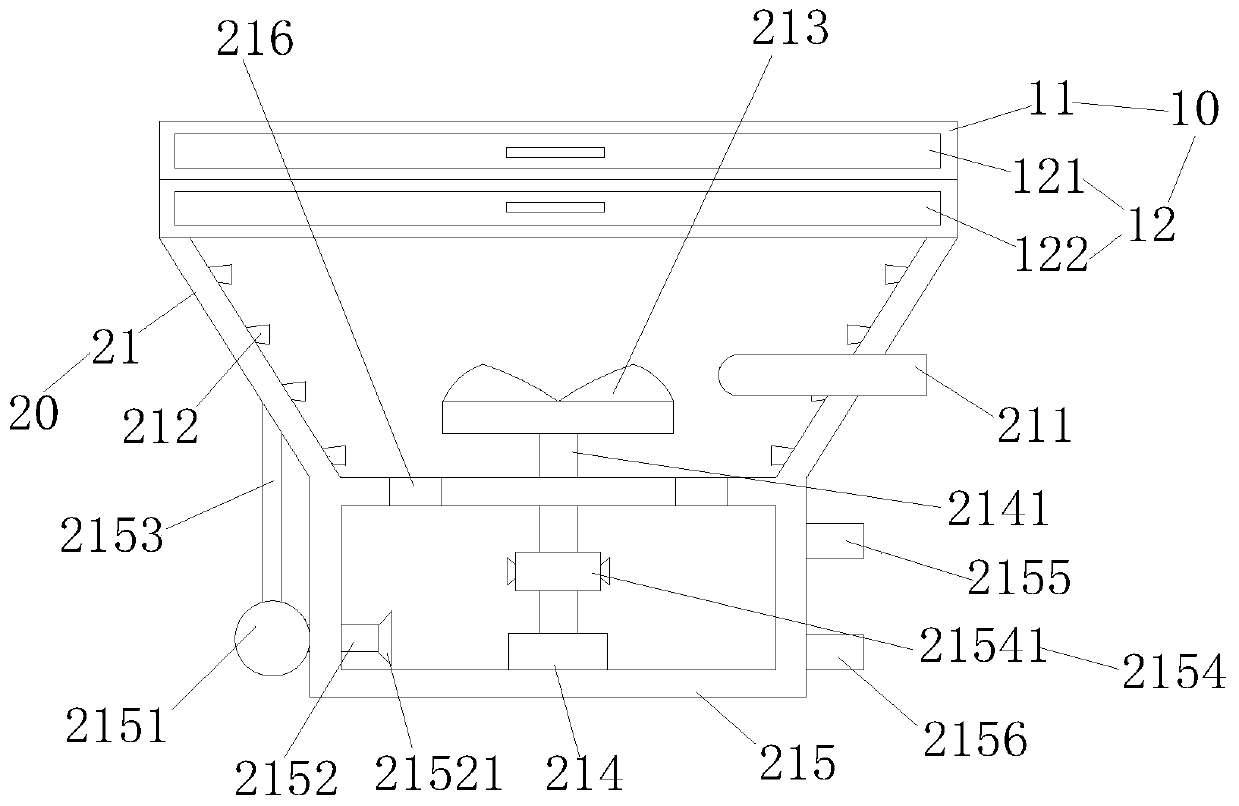

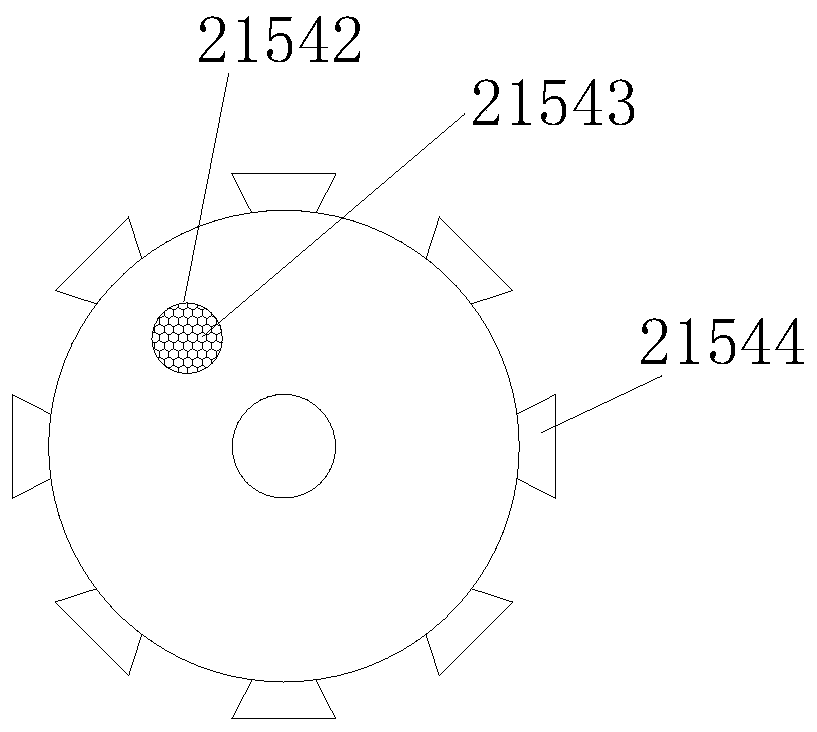

Intelligent mineral powder centrifuge for exploration

ActiveCN105964420AImprove centrifugal separation effectAutomatic control of centrifugation programCentrifugesAutomatic controlElectric machinery

The invention discloses an intelligent mineral powder centrifuge for exploration. The intelligent mineral powder centrifuge comprises a bracket, a centrifugal barrel, a mineral powder slurrying device and an intelligent controller; the bracket is provided with a top plate, and the top plate is provided with a supporting platform; the centrifugal barrel is installed on the bracket, the two ends of the centrifugal barrel are provided with rotating shafts, and a feeding window is installed on the centrifugal barrel; a reducer is installed on one side of the top plate, a servo motor is installed at one end of the reducer, and a belt is arranged at the other end of the reducer; the intelligent controller is installed on one side of the bracket, and the mineral powder slurrying device is installed on one side of the top plate; a slurry detector is installed under the mineral powder slurrying device, and a feeding pipe is arranged under one side of the mineral powder slurrying device; and the bracket is provided with a discharging funnel, and a slurry discharging pipe is installed below the bracket. The intelligent mineral powder centrifuge for exploration has the beneficial effects that the centrifugal procedure is automatically controlled by detecting the mineral powder component in advance, the mineral powder centrifuging and separating effects are improved, and energy can be saved.

Owner:泰安泰山科技有限公司

Refluxing type filter connector

InactiveCN104436850ASpeed up filteringGuaranteed filtering effectFiltration circuitsCycloneFiltration

The invention relates to a refluxing type filter connector. The refluxing type filter connector comprises a cyclone separating part and a confluxing separating part, wherein the cyclone separating part mainly comprises a connecting mechanism for injecting fluid into the cyclone separating part, the flow-in fluid is subjected to refluxing by one refluxing mechanism after being filtered primarily, the fluid is subjected to rotating by a main body with a spiral cyclone groove, impurities with different masses are separated, then the fluid is subjected to secondary separation and filtration by a gradually-flared separation component in the confluxing separating part, then the fluid is subjected to third separation by a simple structure, the installation is convenient and the manufacture cost is low.

Owner:CHONGQING WEST LINE TECH

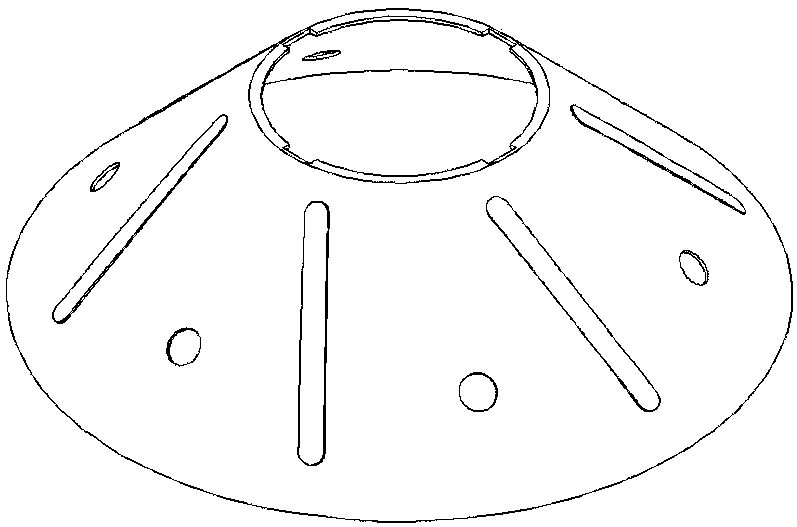

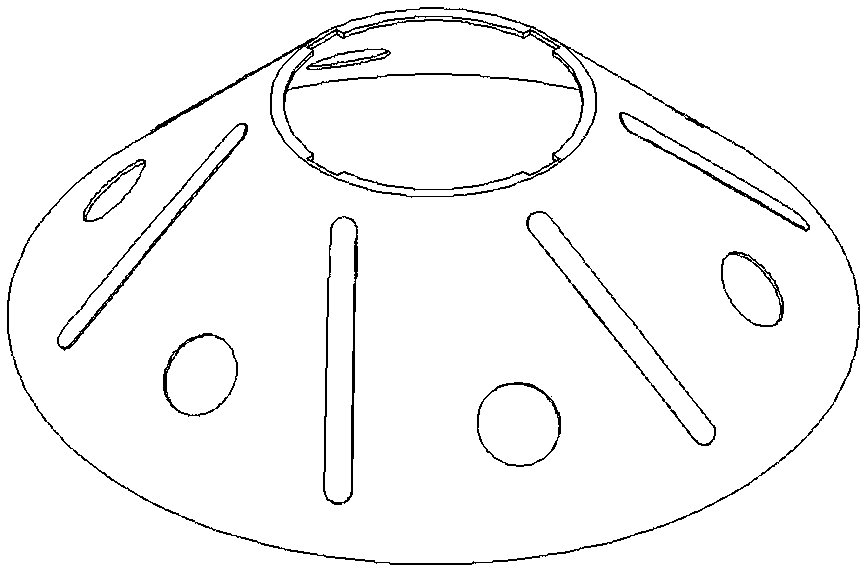

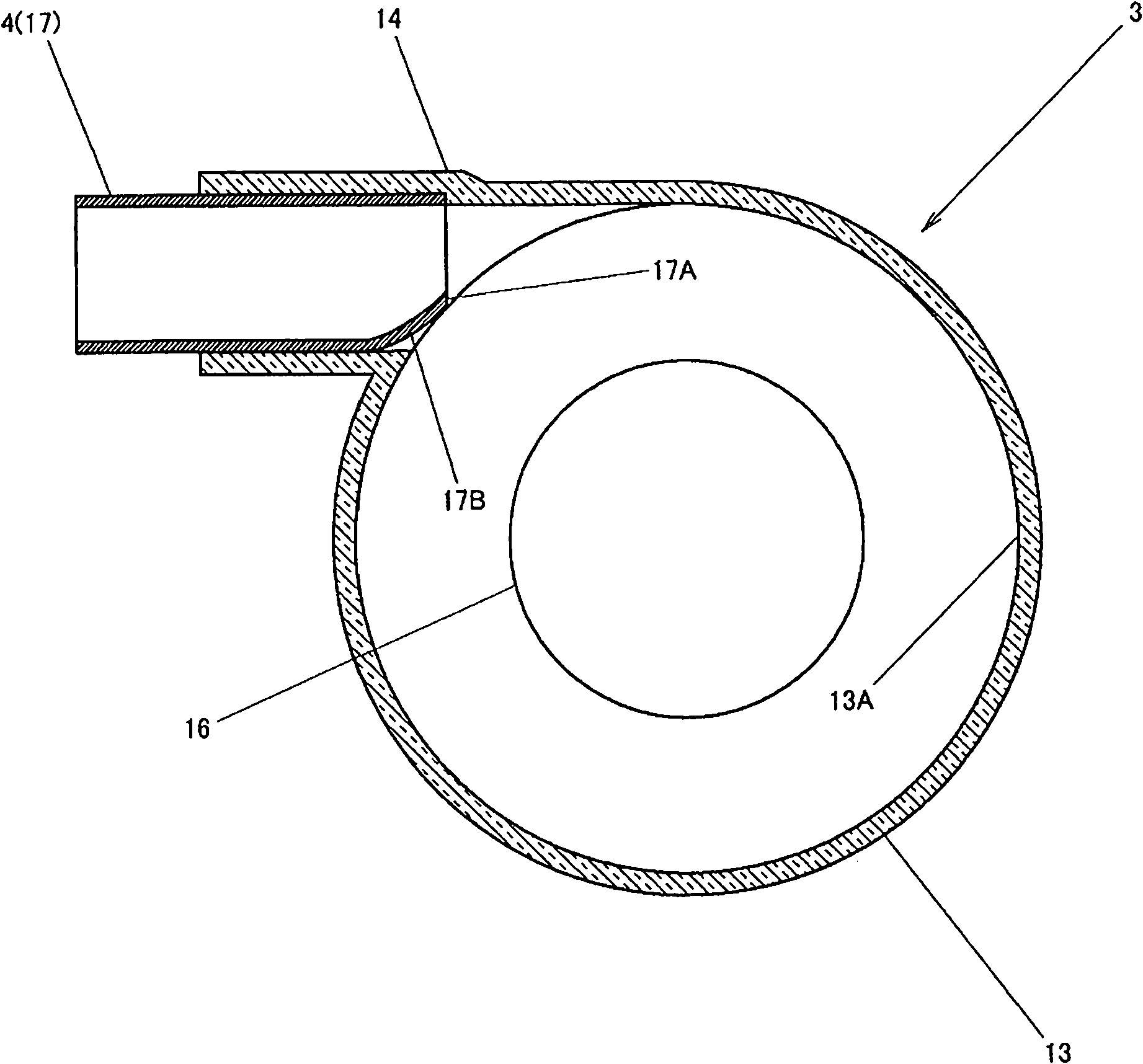

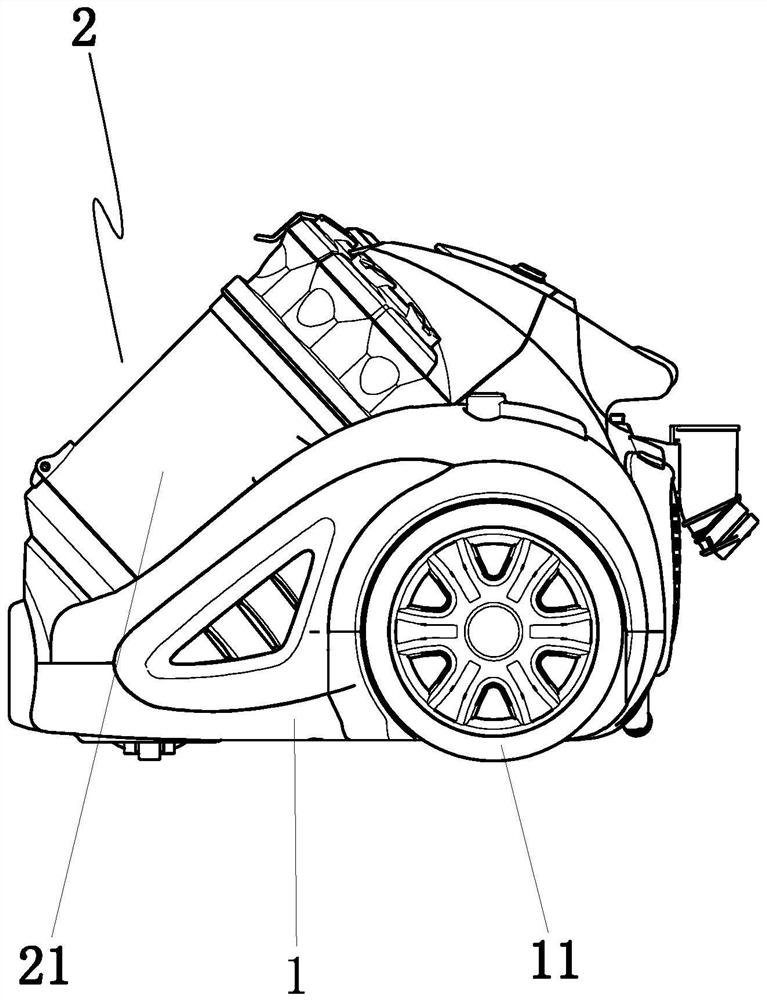

Whirlwind type electric dust collector

A whirlwind type electric dust collector which has a low cost and an improved whirlwind effect is provided. The electric dust collector comprises a dust collector main body (2) with an electric blower (5) and a whirlwind type dust collecting part (3) equipped on the dust collector main body (2) in a freely detachable way. The whirlwind type dust collecting part (3) comprises a whirlwind cylinder (13) and an importing part (14) for importing air flows along the inner wall (13A) of the whirlwind cylinder (13). An inserting cylinder part (17) of a drawing flexible tube part (4) is formed and can be inserted into the importing part (14). Meanwhile, a bent part (17B) is equipped. The bent part is bent towards the peripheral side of the whirlwind type dust collecting part (3) along one end part (17A) of the inserting cylinder part (17) and the central side of the whirlwind type dust collecting part (3). Therefore, a simple and inexpensive structure is formed. Furthermore, the whirlwind return flow can be through from the peripheral side of the whirlwind cylinder (13) and the angular speed of the whirlwind return flow can be improved. Consequently, the centrifugal separation is enhanced.

Owner:TWINBIRD CORP

An intelligent mineral powder centrifuge for exploration

ActiveCN105964420BImprove centrifugal separation effectAutomatic control of centrifugation programCentrifugesAutomatic controlReduction drive

The invention discloses an intelligent mineral powder centrifuge for exploration. The intelligent mineral powder centrifuge comprises a bracket, a centrifugal barrel, a mineral powder slurrying device and an intelligent controller; the bracket is provided with a top plate, and the top plate is provided with a supporting platform; the centrifugal barrel is installed on the bracket, the two ends of the centrifugal barrel are provided with rotating shafts, and a feeding window is installed on the centrifugal barrel; a reducer is installed on one side of the top plate, a servo motor is installed at one end of the reducer, and a belt is arranged at the other end of the reducer; the intelligent controller is installed on one side of the bracket, and the mineral powder slurrying device is installed on one side of the top plate; a slurry detector is installed under the mineral powder slurrying device, and a feeding pipe is arranged under one side of the mineral powder slurrying device; and the bracket is provided with a discharging funnel, and a slurry discharging pipe is installed below the bracket. The intelligent mineral powder centrifuge for exploration has the beneficial effects that the centrifugal procedure is automatically controlled by detecting the mineral powder component in advance, the mineral powder centrifuging and separating effects are improved, and energy can be saved.

Owner:泰安泰山科技有限公司

A swirl filter joint

Owner:CHONGQING WEST LINE TECH

A range hood with high oil separation degree and its built-in spiral separation device

ActiveCN106813281BIncrease cooling areaEasy to separateDomestic stoves or rangesLighting and heating apparatusOil and greasePulp and paper industry

The invention provides a high-grease-separation-degree extractor hood and a built-in spiral separation device thereof. The built-in spiral separation device comprises an inner shell, a cylinder and spiral plates; the inner shell is connected with the interior of an outer shell of an overall machine of the extractor hood; the outer edge of the upper end of the inner shell and the interior of the outer shell of the overall machine are in sealed connection, a ventilating duct for smoke discharging is formed in the middle portion of the inner shell, and a flue is formed by the outer side of the inner shell and the outer shell of the overall machine; the top of the cylinder is connected with the inner shell, at least one ventilating opening is formed in the periphery of the top of the cylinder, and the bottom of the cylinder is closed and is provided with an oil collecting pipe; the cylinder is vertically fixed into the flue and divides the flue into an outer side flue close to the outer shell of the overall machine and an inner side flue close to the inner shell; the outer side flue is communicated with a smoke inlet of the extractor hood, and the inner side flue is communicated with the ventilating duct; and the spiral plates are fixedly installed on the inner side and the outer side of the cylinder correspondingly. The smoke inlet of the extractor hood is communicated with a smoke outlet of the extractor hood through the outer side flue, the ventilating openings, the inner side flue and the ventilating duct in sequence.

Owner:XI AN JIAOTONG UNIV

A secondary return type filter joint

ActiveCN104399311BIncrease flow ratePrevents affecting filter qualityFiltration circuitsRefluxFiltration

A related secondary reverse-flow type filtering joint comprises a swirling separation part, a conflux separation part and a reverse flow part; the swirling separation part rotates a fluid mainly through a main body provided with a spiral swirling tank, so that impurities with different mass are separated; the fluid is subjected to secondary separation filtration in a separation assembly with a gradually divergent opening in the conflux separation part; and then the reverse flow part enables impurities deposited in the separation assembly to flow back to the swirling separation part through a liquid flow. Therefore, secondary separation and secondary reverse flow of the fluid are realized through the simple structure, obstruction of the conflux separation part caused by excessive impurities is effectively prevented, and the secondary reverse-flow type filtering joint is convenient to mount and low in cost.

Owner:JIANGSU SHENGLI DETECTION INSTR CO LTD

Inwardly double inlet-type multistage separation type dust collector

ActiveCN108903773AStrong vacuuming abilityEasy to separateSuction filtersExhaust-air diffusionCycloneCyclonic separation

The invention discloses an inwardly double inlet-type multistage separation type dust collector. The dust collector comprises a housing, a dust cup and a dust collection motor. The dust cup comprisesa cup body, a cup cover and a bottom cover. A first air inlet and a first air outlet are arranged in the dust cup. The inside of the cup body is equipped with a filter cylinder and a second-stage separator. The second-stage separator separates the cup cover from the cup body. The second-stage separator comprises multiple cyclone separation cones. Lower end openings of the cyclone separation conesare less than the opening diameter of the upper end. The side wall of each cyclone separation cone is equipped with two tangential air supply pipes located in the interior of the cup cover. The lowerend of each cyclone separation cone communicates with the interior of the filter cylinder. The upper end of each cyclone separation cone communicates with the interior of the cup cover. The housing isequipped with a primary suction opening and a main discharge opening. The inwardly double inlet-type multistage separation type dust collector has the following beneficial effects: air flows can be dispersed in order to increase relative flow speed of each dispersion air flow; additionally, by increasing relative air inlet amount, centrifugal separation effect is enhanced; the final separation effect of dust is improved; and the dust collection capability is strong.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

Cyclone separator and filtering assembly

The invention discloses a cyclone separator. The cyclone separator comprises a first separation cavity, a second separation cavity, an air outlet and a dust discharge opening. The first separation cavity comprises a bottom surface in the reversely-conical structure and multiple air-guide blades in arc structures. The multiple air-guide blades are uniformly and spirally arranged onto the bottom surface in order to form multiple air channels. An air channel inlet is formed by an outer end of one air-guide blade and an outer end of an adjacent air-guide blade. An air channel outlet is formed by an inner end of one air-guide blade and an inner end of an adjacent air-guide blade. The first separation chamber communicates with the bottom end of the first separation cavity. The bottom surface ofthe second separation cavity is a spirally-downward channel which is coaxial to the bottom surface of the first separation cavity. The air outlet is arranged at the top end of the first separation cavity. The dust discharge opening is arranged at the tail end of a channel of the second separation cavity. The invention also discloses a filtering assembly. The cyclone separator is equipped with twoseparation cavities which can perform cyclone separation twice on dust-laden gas. Therefore, better filtering effect is obtained.

Owner:PUPPY ELECTRONICS APPLIANCES INTERNET TECH (BEIJING) CO LTD

Oxidized polyethylene separation tower and method

ActiveCN109999538AAchieve separationImport uniformLiquid separationFiltration circuitsTowerMaterial transfer

The invention discloses an oxidized polyethylene separation tower. The oxidized polyethylene separation tower comprises a base, wherein a solid-liquid separation mechanism and a liquid-liquid separation mechanism are mounted on the upper end surface of the base and are communicated through a connecting pipe; a feeding pipe is communicated with the solid-liquid separation mechanism; a light liquiddischarging pipe and a heavy liquid discharging pipe are communicated with the liquid-liquid separation mechanism; a drive mechanism and a transmission mechanism are mounted at the upper end of the liquid-liquid separation mechanism. The invention further discloses an oxidized polyethylene separation method. The method comprises following steps: S1, filtering; S2, screening; S3, solid-liquid separation; S4, liquid-liquid separation; S5, repeating of operation. The structure is ingenious, the solid-liquid separation mechanism and the liquid-liquid separation are combined, separation of smaller-particle waxy semi-solids and waxy solids and separation of white viscous oxidized polyethylene with different molecular weights are realized, separation speed of oxidized polyethylene is increased, and loss in a material transfer process is reduced.

Owner:NANJING YANGZI FINE CHEM

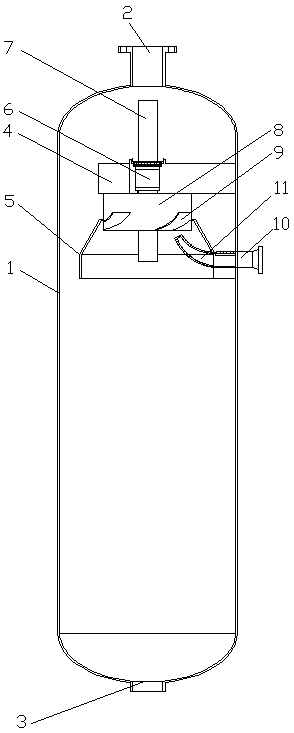

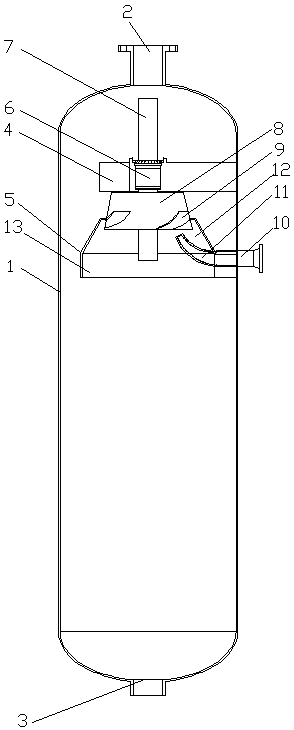

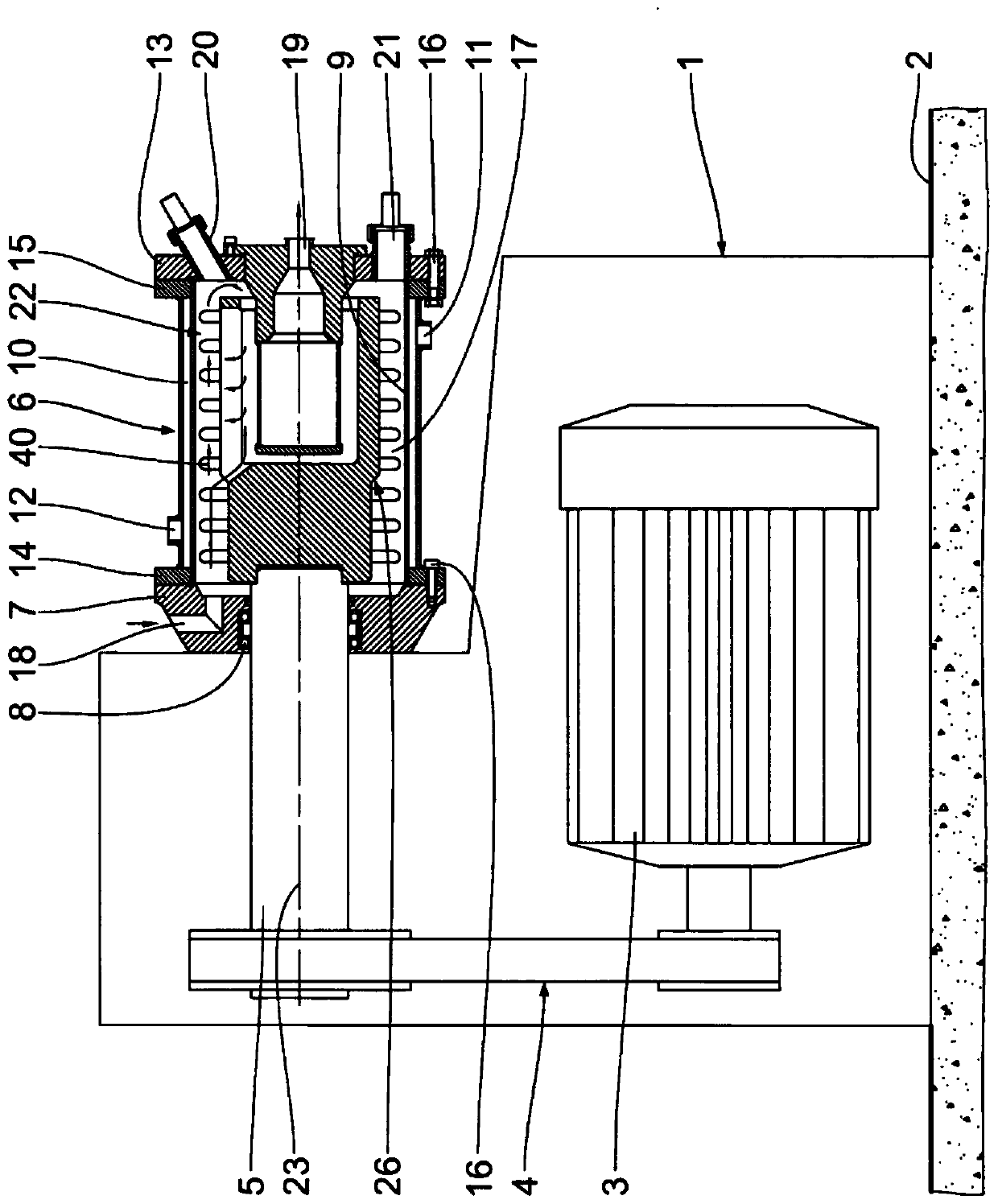

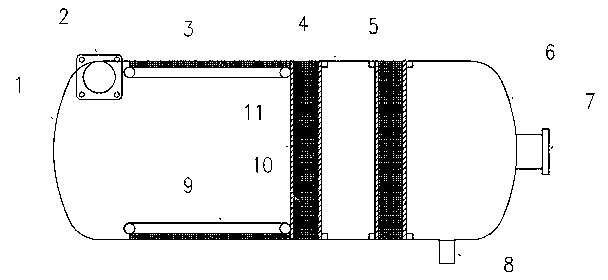

A horizontal oil separator

ActiveCN103388942BEasy to separateReduced fine filter requirementsRefrigeration componentsFiltrationOil separation

The invention provides a horizontal type oil separator, which comprises a horizontal type barrel (4), an air inlet pipe (2), an air escape pipe (7), an oil discharge outlet (8) and an oil separation component, wherein the air inlet pipe (2) and the air escape pipe (7) are respectively arranged at the two ends of the barrel (4); the oil discharge outlet (8) is arranged at the bottom of the barrel (4); the oil separation component is arranged inside the barrel (4); and the oil separation component comprises a centrifugal oil separator and a filter type oil separator which are arranged along the front and back of gas stroke. According to the horizontal type oil separator, the structural feature of combining rotating centrifugal force and silk screen refined filtration is utilized, the kinetic energy of gas per se is fully utilized, most oil drops of large diameter are removed under the condition of not increasing resistance, the requirements of refined filtration sections are reduced, the oil-gas separation is more adequate, and the oil separation effect is improved under the condition of not increasing the size and the resistance of the barrel; and meanwhile, the centrifugal separation effect is intensified by utilizing a spoiler and an adherence silk screen.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

A kind of oil-gas separation device with impeller

ActiveCN113250824BCounteract flow resistanceEasy to separateLeakage preventionGas turbine plantsImpellerCircular disc

The invention discloses an oil-gas separation device with an impeller, which comprises a central disc, an impeller, a filter screen structure, an oil collecting ring and two cover plates; the two cover plates and the oil collecting ring form two central holes on the bottom surface The cylindrical structure is fixedly sleeved on the central disc; one end of the impeller is connected to the cylindrical interior formed by the cover plate and the oil collection ring, and the other end of the impeller is sealed; the filter mesh structure includes a circular The central installation part and the filter screen fixedly connected on both sides of the central installation part, the central installation part is fixedly sleeved on the edge of the disc part, and the side of the filter screen away from the central installation part is sealed and connected with the inner wall of the cover plate; the present invention The oil and gas are pressurized and accelerated by the impeller, which can offset the flow resistance; the oil and gas mixture can be filtered twice to improve the oil and gas separation effect; the air flow channel is arranged with a support plate, which can enhance the air flow rotation and improve the centrifugal separation effect.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Secondary chlorine injection device for fluidized chlorination furnace of fine-grained titanium raw material

InactiveCN104891561BEnhanced rotational shear interactionsImprove centrifugal separation effectTitanium halidesTitaniumInjection device

The invention discloses a secondary chlorine gas injection device for a fine-particle titanium raw material boiling chlorination furnace. The secondary chlorine gas injection device comprises a boiling chlorination reactor main section, a secondary chlorine gas injection section, a furnace top, a secondary chlorine gas introducing hole, an inverted U-shaped tube shell and a cyclone separator. The cyclone separator is used for separating solid powder and gaseous TiCl4; an ascending tube is arranged in the middle of the cyclone separator, and the lower part of the cyclone separator is communicated with a circulating return leg. The secondary chlorine gas injection section, an outlet of the furnace top, the cyclone separator and the circulating return leg are communicated in sequence, and an inverted U-shaped pipeline is formed at the furnace top. The inverted U-shaped tube shell is arranged outside the inverted U-shaped pipeline and forms a sealed secondary chlorine gas injection channel together with the inverted U-shaped pipeline. The mutual effect of rotational shear of gas and solids at the upper part of the boiling chlorination furnace and the centrifugal separation effect are enhanced, so that the escaped fine particles which not completely react are reduced; and meanwhile, the chlorination reaction efficiency and the yield of TiCl4 are increased, and the temperature of the TiCl4 gas at the top of the boiling chlorination furnace is balanced.

Owner:CHONGQING UNIV

An inner double-inlet multi-stage separation vacuum cleaner

ActiveCN108903773BStrong vacuuming abilityEasy to separateSuction filtersExhaust-air diffusionThermodynamicsCyclonic separation

The invention discloses an inwardly double inlet-type multistage separation type dust collector. The dust collector comprises a housing, a dust cup and a dust collection motor. The dust cup comprisesa cup body, a cup cover and a bottom cover. A first air inlet and a first air outlet are arranged in the dust cup. The inside of the cup body is equipped with a filter cylinder and a second-stage separator. The second-stage separator separates the cup cover from the cup body. The second-stage separator comprises multiple cyclone separation cones. Lower end openings of the cyclone separation conesare less than the opening diameter of the upper end. The side wall of each cyclone separation cone is equipped with two tangential air supply pipes located in the interior of the cup cover. The lowerend of each cyclone separation cone communicates with the interior of the filter cylinder. The upper end of each cyclone separation cone communicates with the interior of the cup cover. The housing isequipped with a primary suction opening and a main discharge opening. The inwardly double inlet-type multistage separation type dust collector has the following beneficial effects: air flows can be dispersed in order to increase relative flow speed of each dispersion air flow; additionally, by increasing relative air inlet amount, centrifugal separation effect is enhanced; the final separation effect of dust is improved; and the dust collection capability is strong.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

Automobile air conditioning filter cleaner with pre-dust-removal mechanism

PendingCN110126587AIncrease chance of bindingReduce filter pressureCombination devicesAir-treating devicesImpellerFiltration

The invention discloses an automobile air conditioning filter cleaner with a pre-dust-removal mechanism. The automobile air conditioning filter cleaner comprises a filter cleaner body; a pre-dust-removal device is installed on the filter cleaner body; the pre-dust-removal device comprises a pre-dust-removal chamber; an air inlet pipe is installed on the pre-dust-removal chamber, and the air inletpipe is arranged tangentially along the side wall of the pre-dust-removal chamber; atomizing spraying heads are installed on the inner walls of the pre-dust-removal chamber; and impellers are installed inside the pre-dust-removal chamber. According to the automobile air conditioning filter cleaner, air tangentially enters the pre-dust-removal chamber to play the role of centrifugal separation; andthe pre-dust-removal chamber is filled with water mist, on the one hand, the water mist dust removal effect is achieved, dust and the water mist are combined to settle, due to the fact that the air rotates in the pre-dust-removal chamber, the probability of combining the water mist with the dust can be increased, the water mist dust removal effect is enhanced, centrifugal dust removal and water mist dust removal cooperate with each other, the dust removal effect is greatly improved, the filtration pressure of a filter element is decreased, the attaching speed of the dust on the surface of thefilter element is decreased, and the permeability of the filter element is ensured.

Owner:高博集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com