High-grease-separation-degree extractor hood and built-in spiral separation device thereof

A range hood, spiral separation technology, applied in the removal of range hoods, heating methods, household heating and other directions, can solve the problems of increasing noise and vibration of range hoods, shortening the life of range hood components, affecting the safety of use, etc. The effect of reducing grease adhesion, increasing the cooling area of flue gas, and protecting the life of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

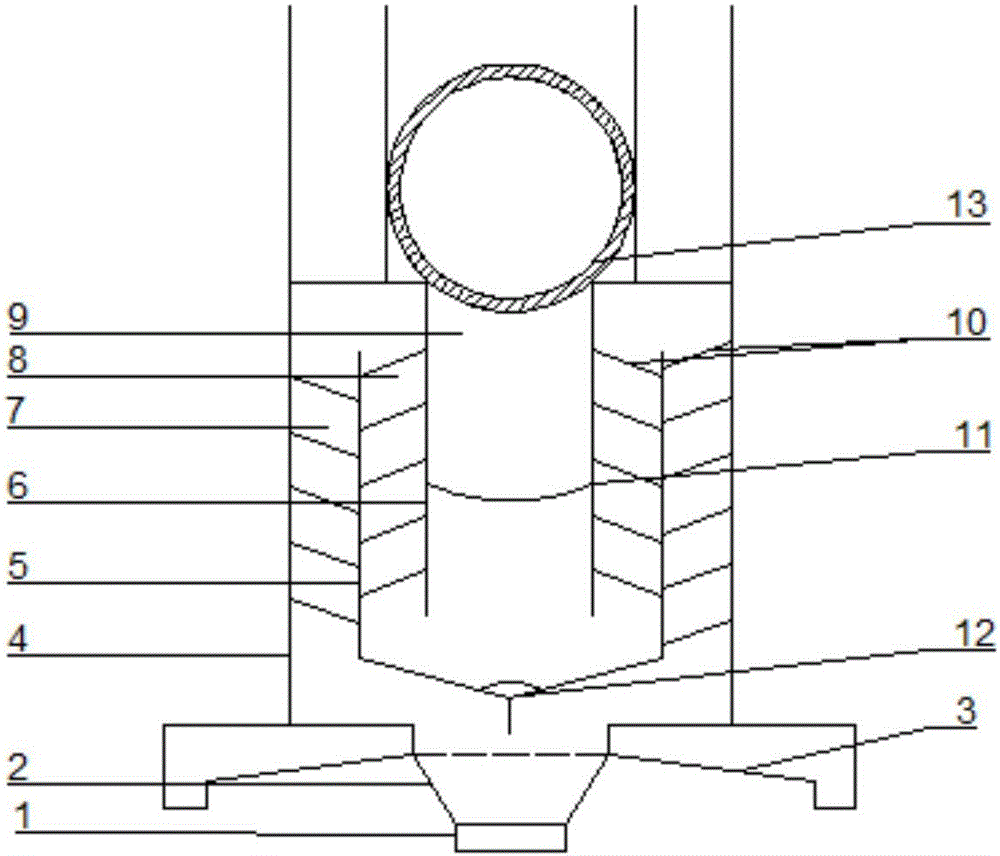

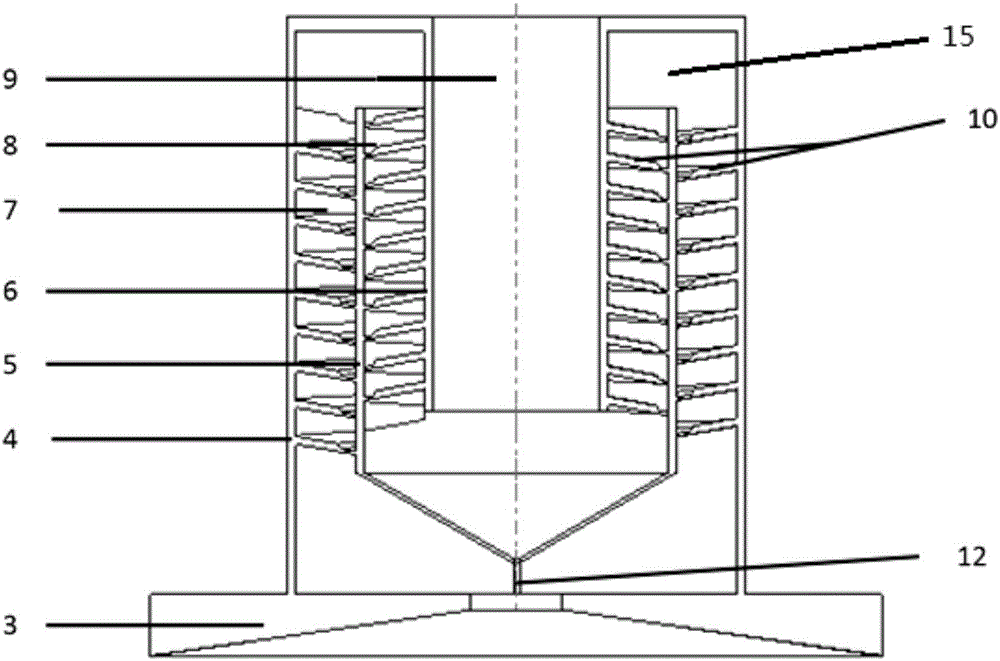

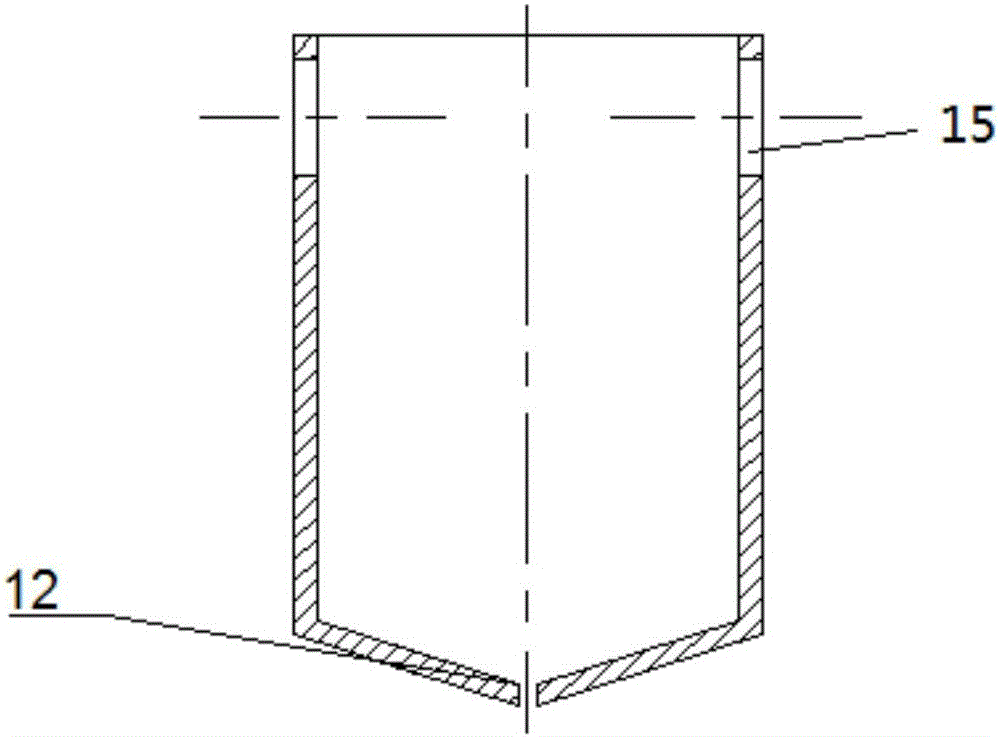

[0027] The invention provides a range hood with high oil separation degree. By increasing the collision chance of flue gas, enlarging the cooling area and strengthening the centrifugal separation effect, the oil separation and collection in the range hood is enhanced, and the oil separation degree of the whole machine is improved. The range hood structure includes a hood casing, a fan 13 installed in the casing, an impeller and a built-in spiral separation device; the built-in spiral separation device includes a cylinder 5 , a spiral plate 10 and a rotating filter screen 11 . The hood shell is composed of the complete machine shell 4 and the inner shell 6 connected thereto. The inner space of the complete machine shell 4 forms a chassis, and the cylinder 5 is vertically fixed in the chassis. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com