Stirring mill

A grinding machine and grinding technology, which is applied in the direction of mixers, mixers with rotating stirring devices, dissolution, etc., can solve the problems that the grinding auxiliary body cannot be fully uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

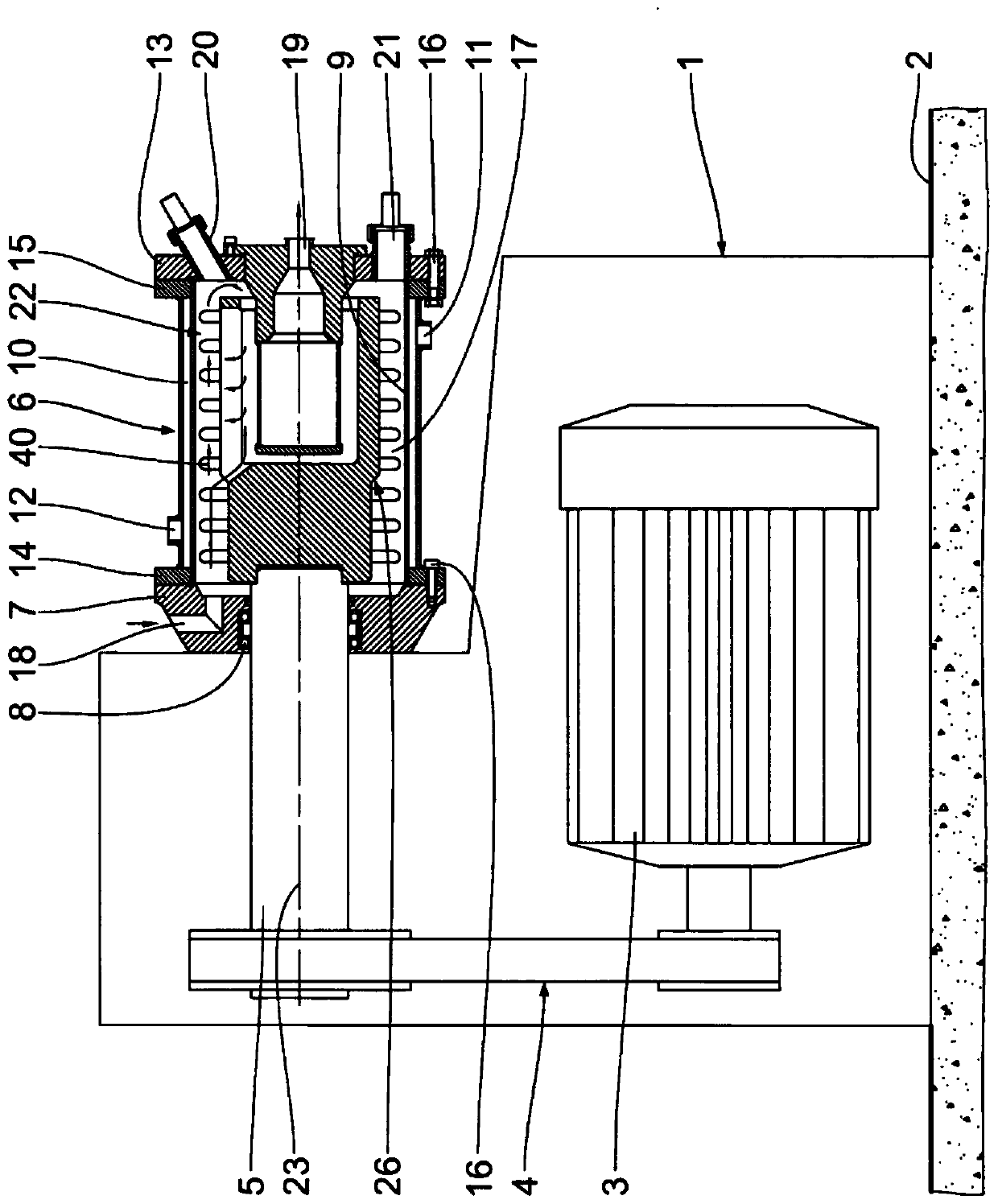

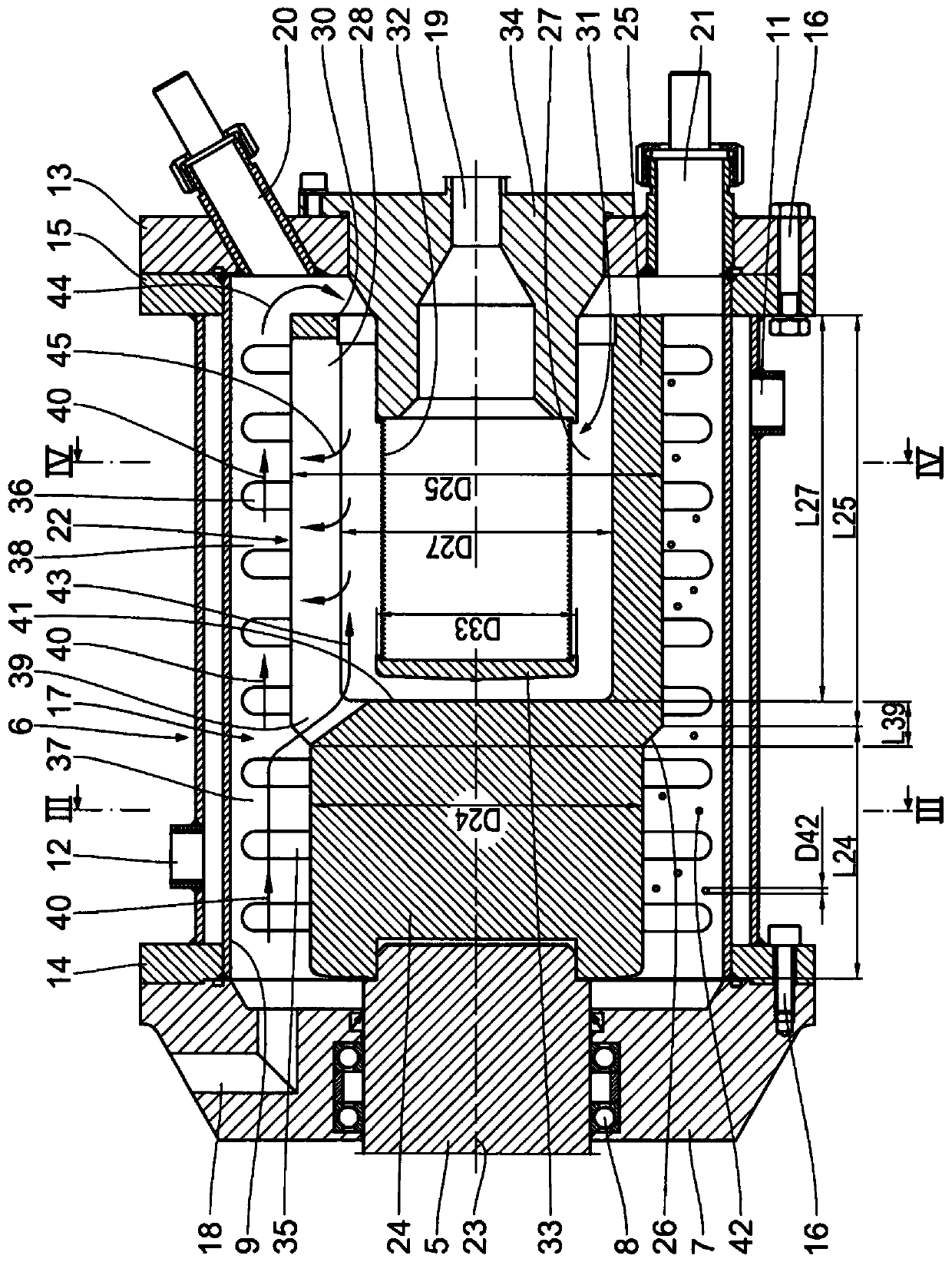

[0021] as available from figure 1 As seen in the figure, a horizontal agitating mill has a frame 1 supported on the ground 2 . Arranged in the lower region of the machine frame 1 is a drive motor 3 , which is coupled to a drive shaft 5 by means of a belt drive 4 .

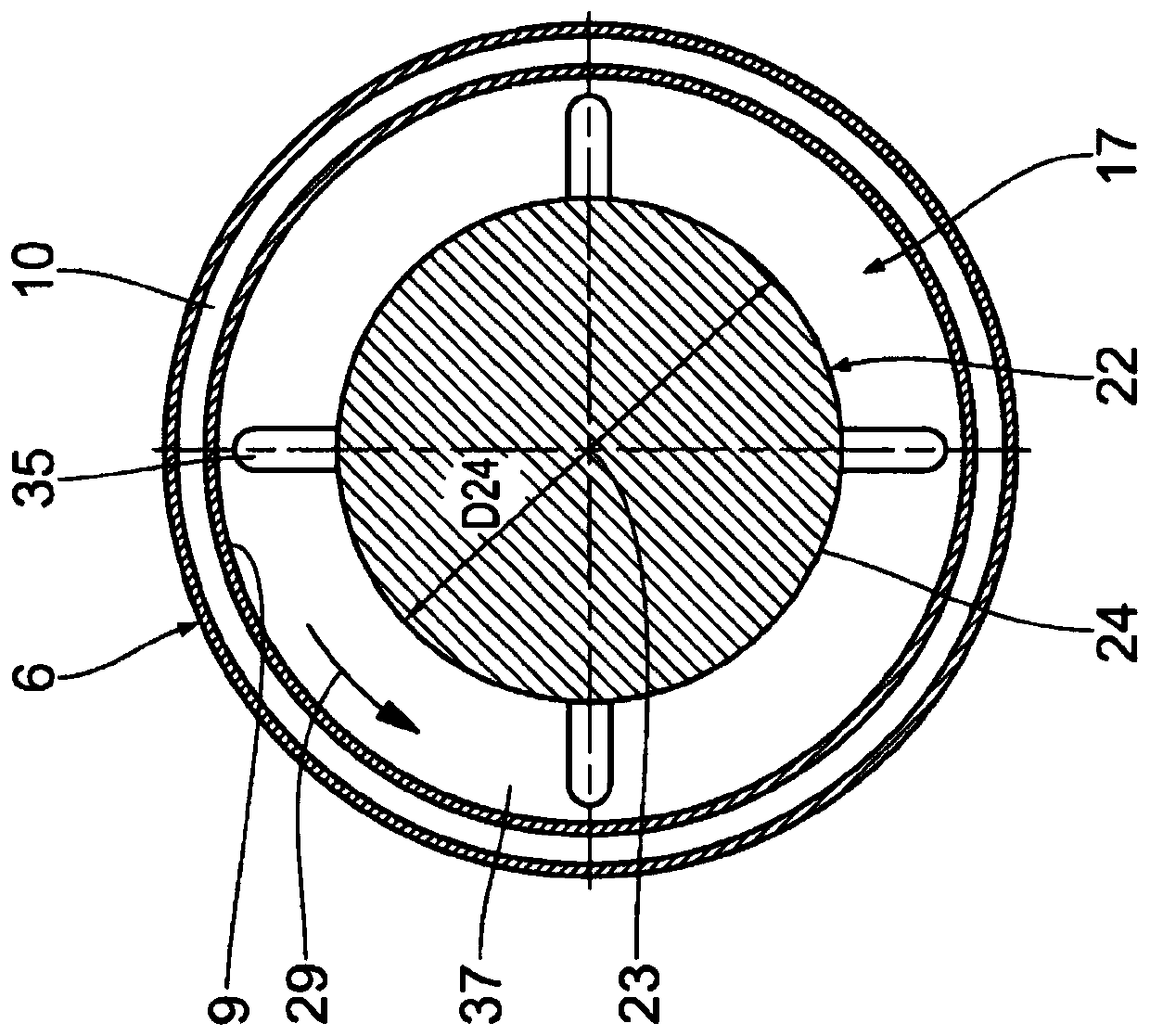

[0022] In the upper region of the frame 1 a horizontal grinding container 6 is fastened to the frame. The grinding container has a first grinding container housing 7 which is mounted on the machine frame 1 and in which the drive shaft 5 is rotatably mounted by means of a roller bearing 8 . The grinding container 6 also has a cylindrical inner wall 9 which is surrounded by a temperature-controlling housing 10 into which a temperature-controlling agent, usually coolant, is introduced via an inlet 11 and discharged via an outlet 12 . At the end opposite the first grinding container cover 7 , ie at a distance from the upper region of the machine frame 1 , the grinding container 6 is closed by a second grinding contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com