Compressor

A technology for a compressor and a compression mechanism, which is applied in the field of compressors, can solve the problems of reduced reliability of compressors, reduced heat exchange capacity of heat exchangers, etc., and achieves the effect of high oil separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

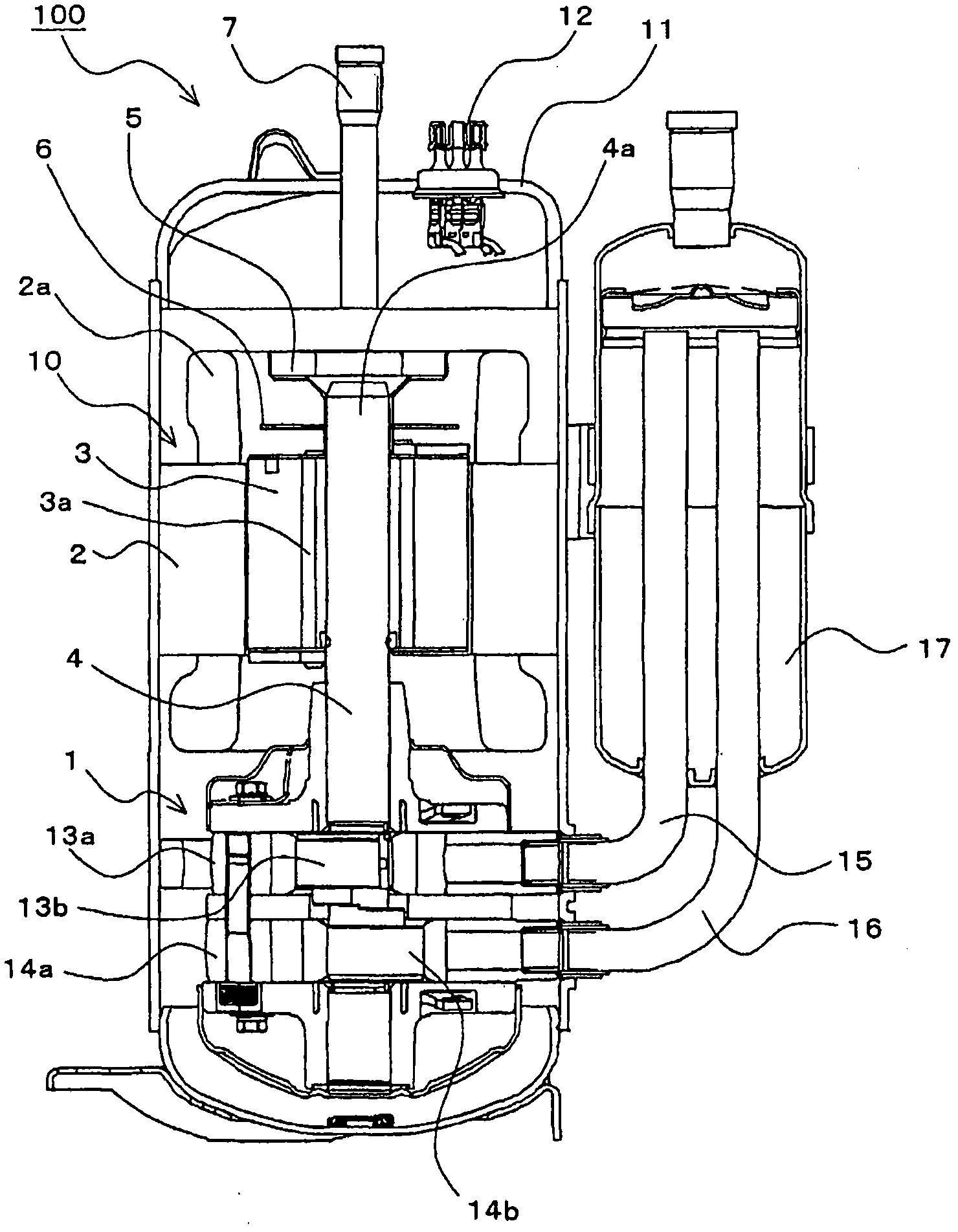

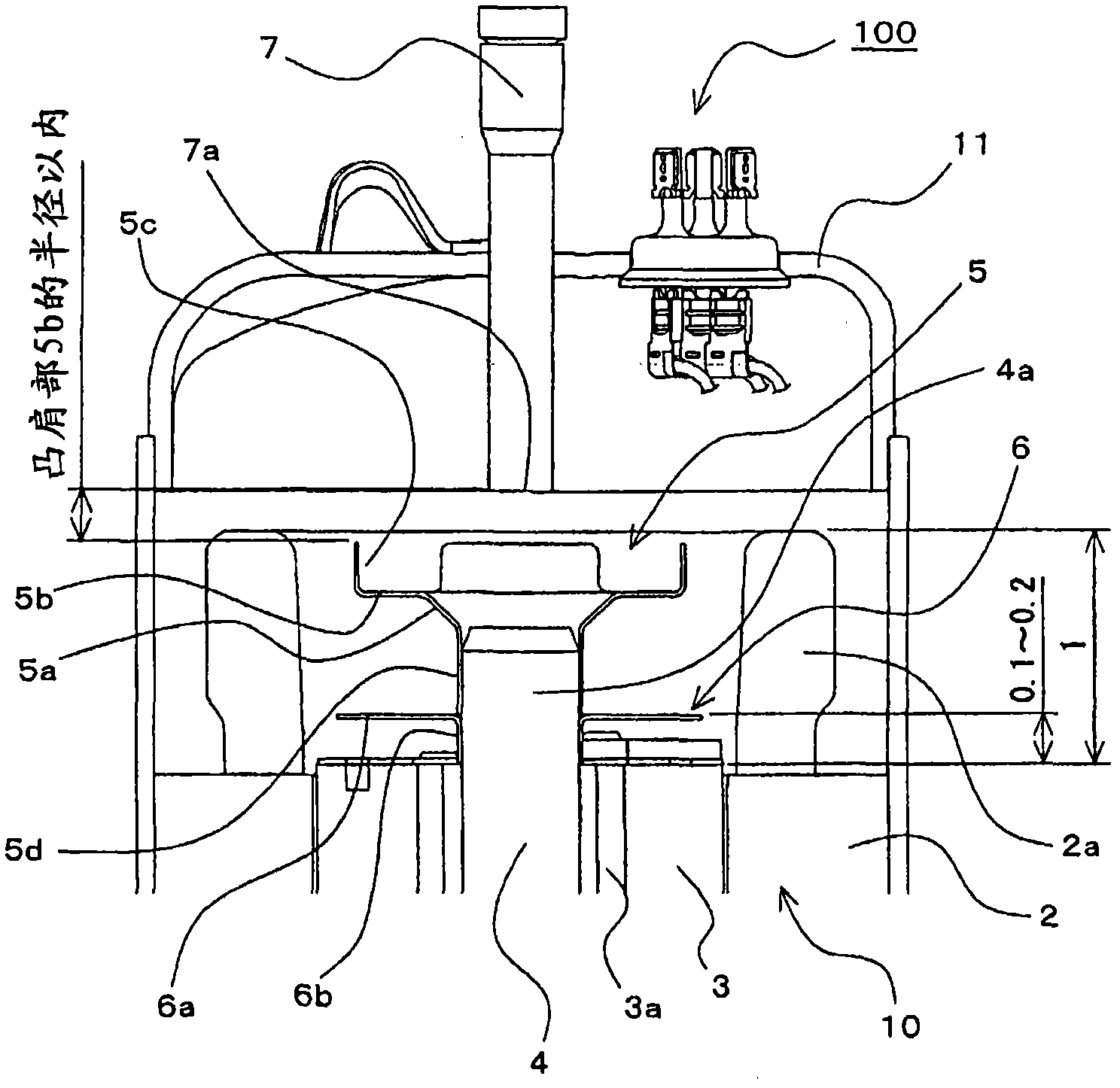

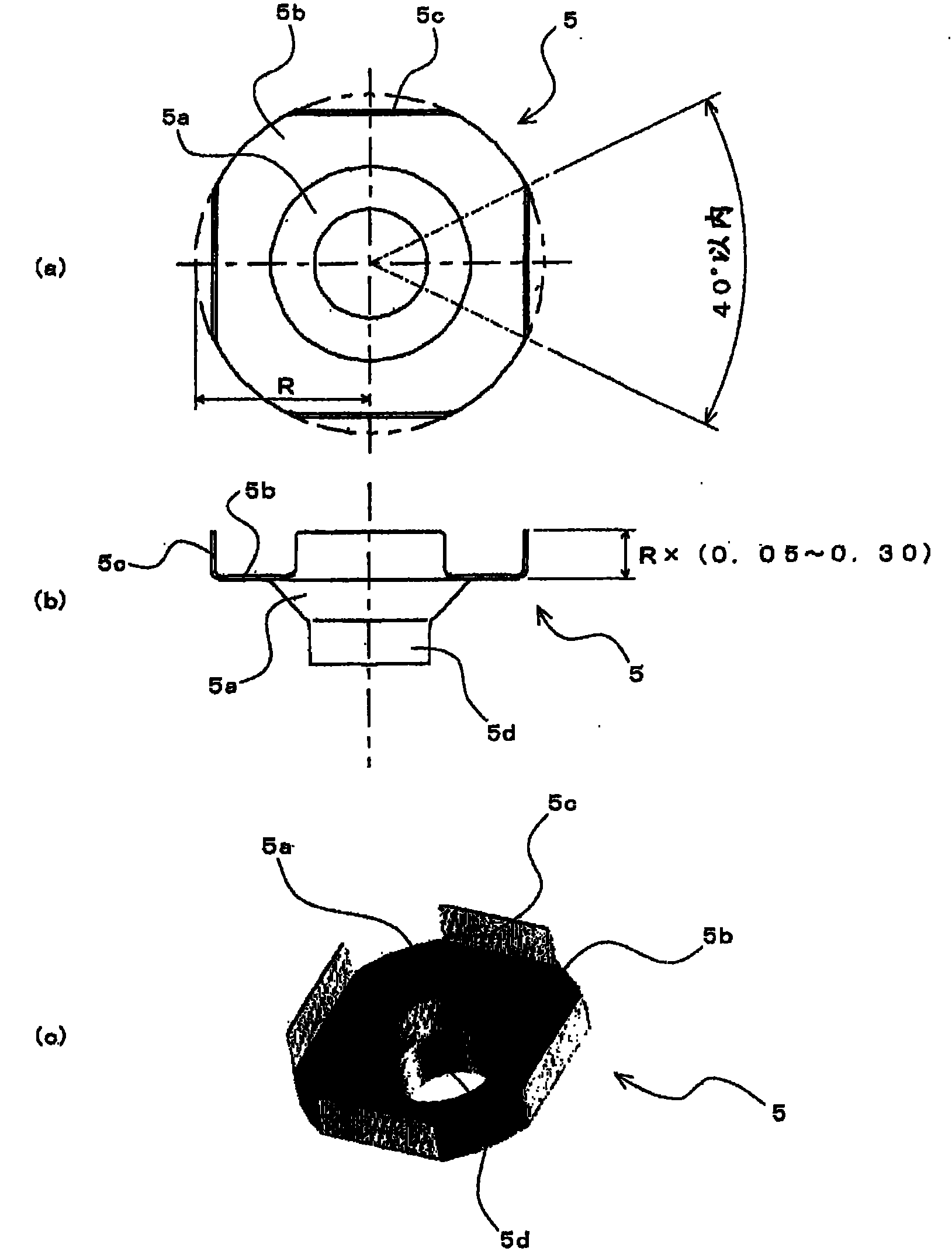

[0020] figure 1 It is a schematic longitudinal sectional view of the compressor according to the embodiment of the present invention. figure 2 to represent figure 1 It is an enlarged view of main parts near the upper part of the shown compressor. in addition, image 3 It is a detailed view showing the first oil separation member provided in the compressor. and, image 3 (a) shows a plan view of the first oil separation member, image 3 (b) shows a side view of the first oil separation member, image 3 (c) shows a perspective view of the first oil separation member. Below, according to these Figure 1 ~ Figure 3 The compressor 100 of this embodiment will be described.

[0021] The compressor 100 sucks in the refrigerant circulating in the refrigeration cycle, compresses it, and discharges it in a state of high temperature and high pressure. The compressor 100 is a hermetic compressor, and a compression mechanism 1 , a motor unit 10 , and the like are provided in a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com