A horizontal oil separator

An oil separator and oil separation technology, used in refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problems of gas short circuit, deterioration of separation effect, insufficient centrifugal force, etc., to reduce requirements, improve oil separation effect, oil and gas Full effect of separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

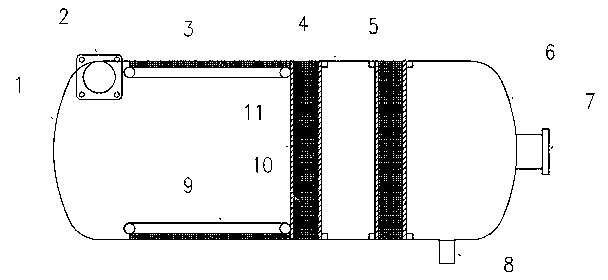

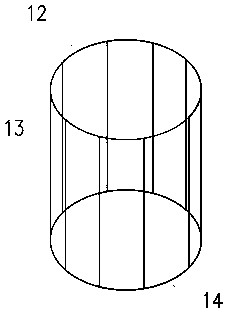

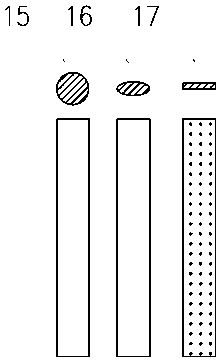

[0030] This implementation is applied to a horizontal oil separator of a large-scale flooded chiller. It consists of a cylinder body 4, a left head 1, a right head 6, two filter cores 10, an air inlet pipe 2, an air outlet pipe 7, an oil discharge pipe 8, a wall-attached wire mesh 3, and a spoiler 9. attached figure 1 The structure shown is installed. Wherein, the two ends of the cylinder 4 are welded with half standard elliptical heads 1 and 6 respectively to form a closed space, and the spoiler 9 is welded by the left circular ring 14, the right circular ring 12 and the spoiler 13. The diagram is attached figure 2 Shown, and the structure of the spoiler 13 is as attached image 3 Shown, can adopt multiple forms such as circular, oval, perforated plate, respectively as cylindrical spoiler 15, oval spoiler 16, perforated plate spoiler 17, perforated plate can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com