Secondary chlorine gas injection device for fine-particle titanium raw material boiling chlorination furnace

A technology of boiling chlorination furnace and filling device, which is applied in the direction of titanium halide, etc., can solve the problems of affecting the operation effect of secondary strong spin separation, difficult to guarantee processing accuracy, and discontinuous dispersion, so as to reduce fine-grained materials. Escape, increase yield, enhance the effect of rotational shear interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific embodiments.

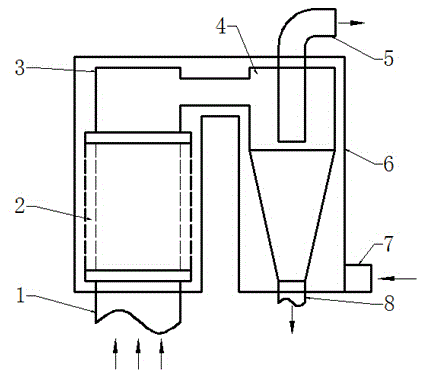

[0018] like figure 1 As shown, the secondary chlorine injection device of the boiling chlorination furnace for fine-grained titanium raw materials includes the main section 1 of the reactor, the furnace top 3, the cyclone separator 4 and the riser pipe 5, and the inlet and outlet at both ends of the furnace top 3 are respectively connected to the reaction The upper end of the main section 1 of the device and the upper end of the cyclone separator 4 form an inverted U-shaped structure, and the lower end of the riser pipe 5 extends into the cyclone separator 4, and a circulation return leg 8 is provided at the lower end of the cyclone separator 4 for solid powder. Return to the fluidized chlorination furnace reactor; it is characterized in that: an inverted U-shaped structure overcoat formed on the furnace roof 3, the upper end of the reactor main section 1 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com