Whirlwind type electric dust collector

A cyclone-type vacuum cleaner technology, applied in the field of cyclone-type electric vacuum cleaners, can solve the problems of increased cost, complicated structure of forming molds, etc., and achieve the effects of simplified structure, easy forming, and restraining the reduction of centrifugal separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

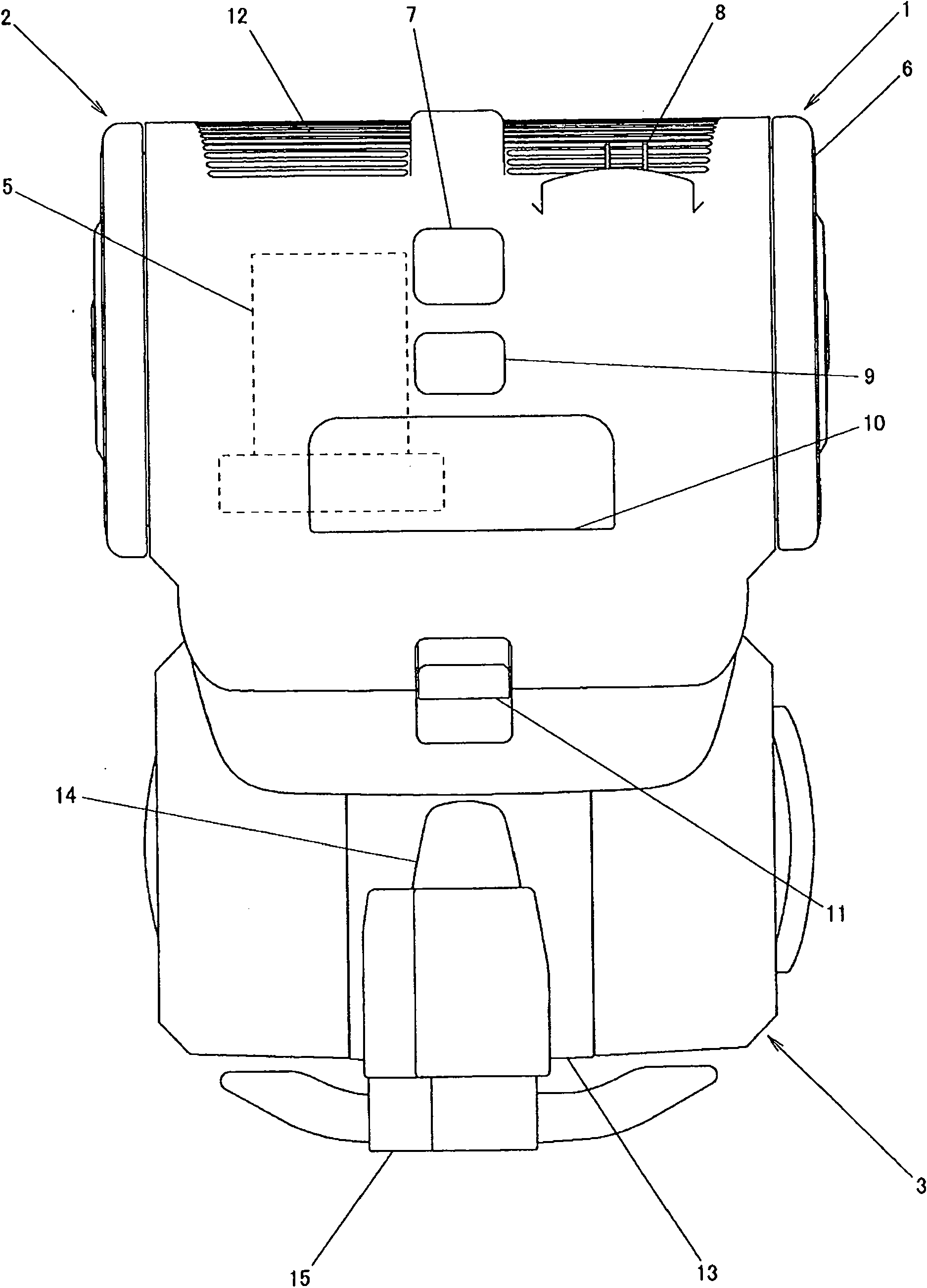

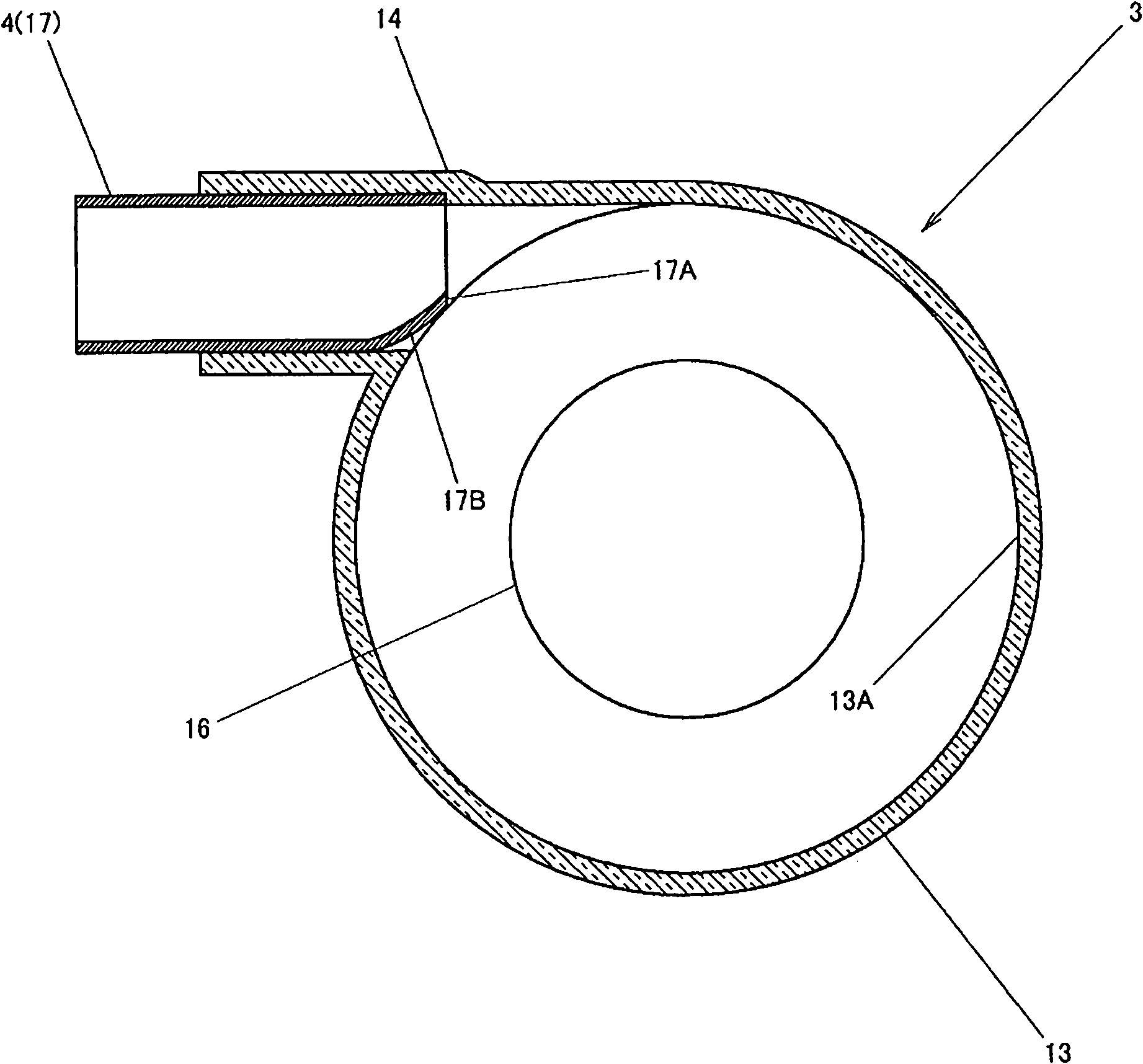

[0013] Hereinafter, with respect to the embodiment of the present invention, based on figure 1 and figure 2 Be explained. 1 is the cyclone electric vacuum cleaner of the present invention. This cyclone electric vacuum cleaner 1 has and is composed of a vacuum cleaner main body 2 , a cyclone dust collecting unit 3 , and a suction hose member 4 .

[0014] The cleaner main body 2 has an electric blower 5 inside. Moreover, the said cleaner main body 2 has the wheel 6, and can move freely on the surface to be cleaned. Moreover, the said cleaner main body 2 has the switch operation part 7 for operating the said electric blower 5 on the upper surface. Moreover, the above-mentioned cleaner main body 2 has the cord winding operation part 9 for winding the power cord which is not shown in figure and the front-end|tip of which provided the electric wire plug 8 on the upper surface. Moreover, the above-mentioned vacuum cleaner main body 2 has the grip part 10 for gripping and convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com