Oil-gas separator for vehicle-mounted air conditioner compressor and vehicle-mounted air conditioner compressor

A technology for oil and gas separators and vehicle air conditioners, which is applied in the field of vehicle air conditioner compressors to achieve the effects of improving centrifugal separation effect, improving service life and enhancing centrifugal separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

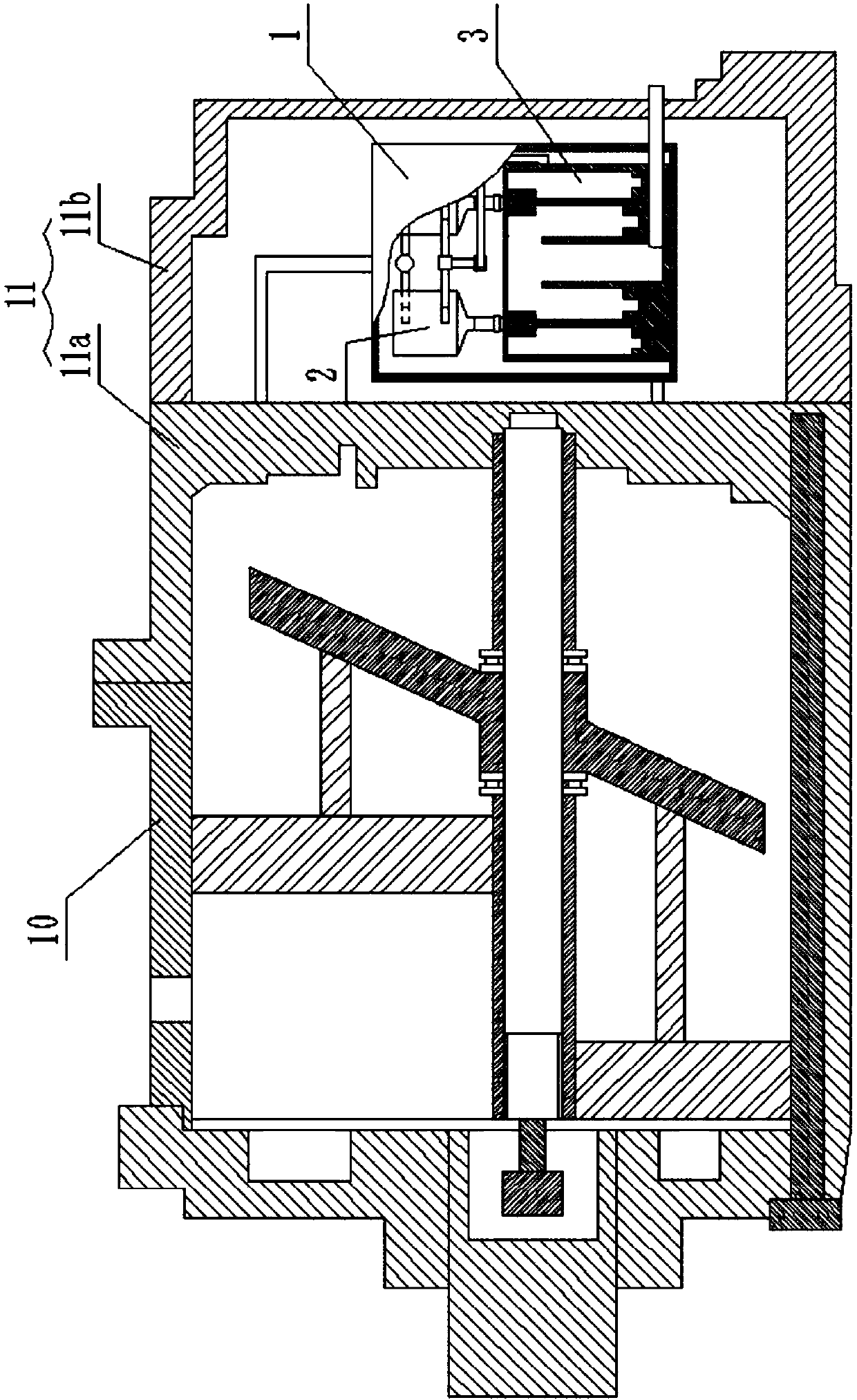

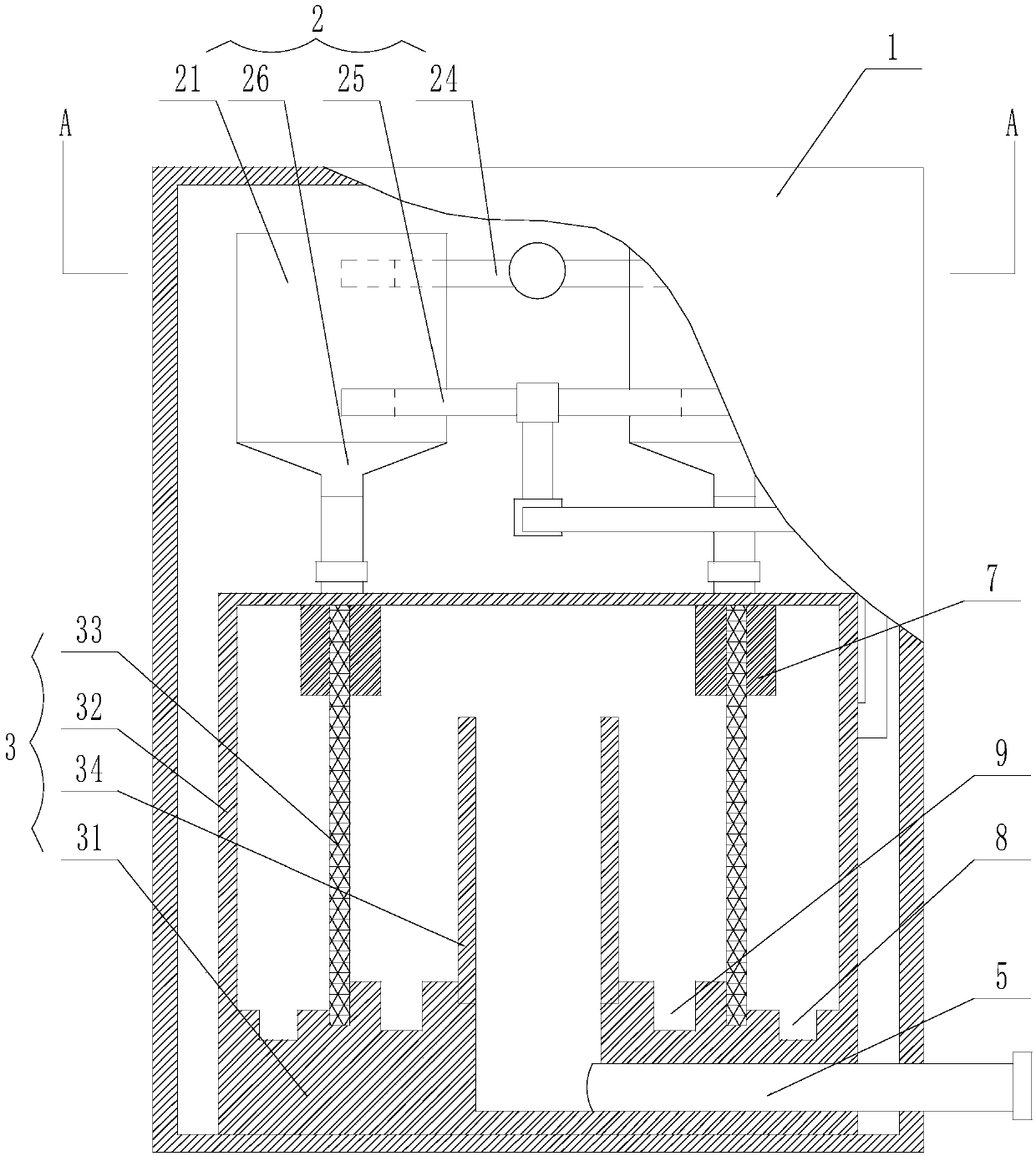

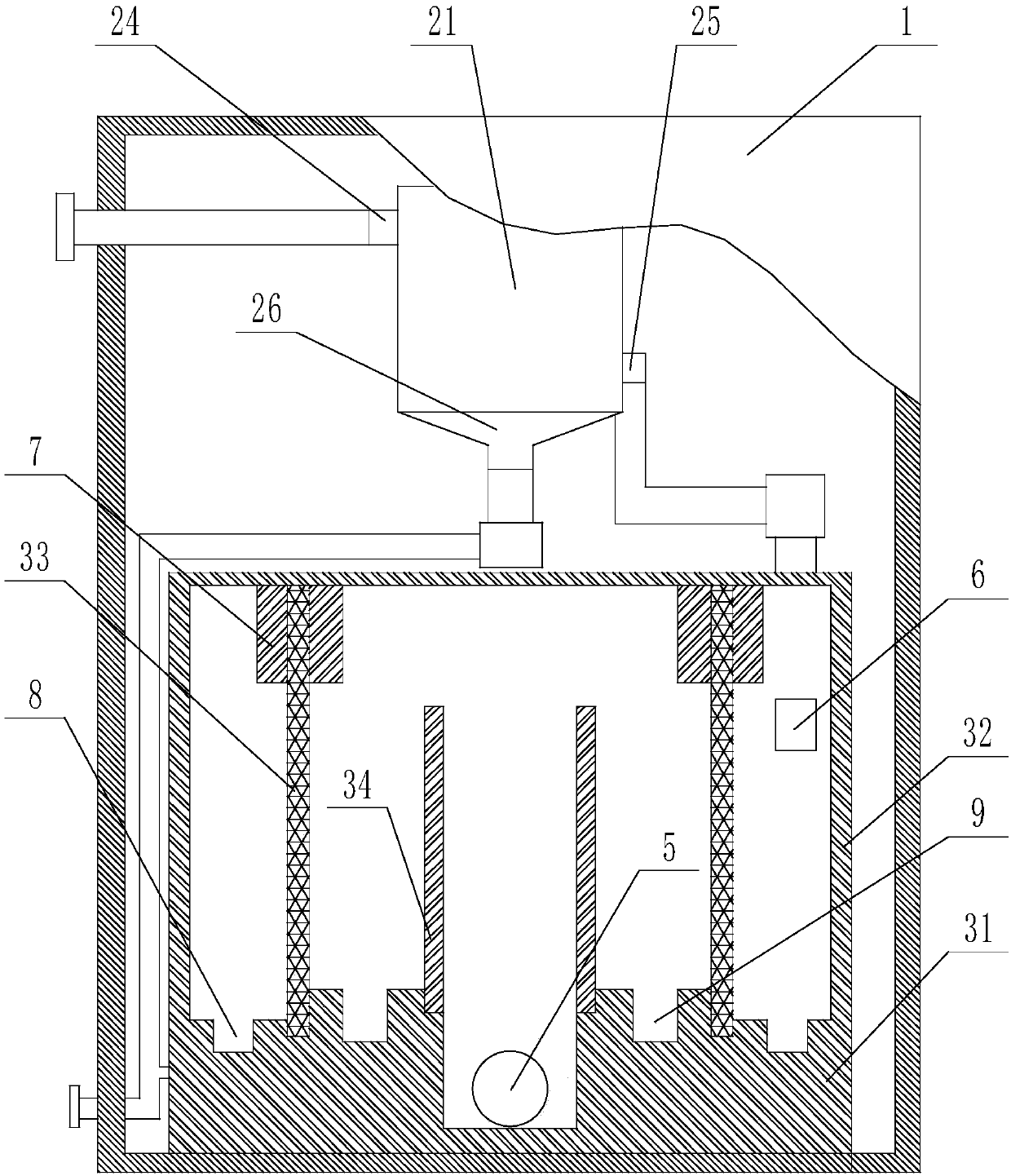

[0034] Such as Figure 1-4 As shown, a vehicle-mounted air-conditioning compressor includes a compressor body 10 and a cylinder head 11 arranged on the compressor body 10. The cylinder head 11 includes an outer cover 11a and an inner cover 11b, and the outer cover 11a is connected to the inner cover 11b. An outer cavity is formed between the covers 11b, and an inner cavity is formed between the inner cover 11b and the compressor body 10, and the oil-gas separator for the vehicle-mounted air-conditioning compressor described in Embodiment 1 is arranged in the outer cavity, and the oil-gas passage The oil discharge passage communicates with the inner cavity pipeline respectively, and the exhaust passage communicates with the outer cover 11a pipeline.

[0035] During operation, the oil-air mixture generated by the compressor body 10 enters the centrifugal separator 21 through the oil-air channel, and under the centrifugal action, the small liquid droplets in the oil-air mixture a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com