Medical high-speed centrifuging equipment and centrifugal rotor

A centrifugal rotor, high-speed technology, applied in the field of medical testing, can solve the problems of increasing the working energy consumption of the centrifuge, the centrifugal separation effect, difficulty in sampling, and trouble, so as to improve the sampling efficiency and sampling data accuracy, and facilitate the disassembly and assembly of the hanging cup. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

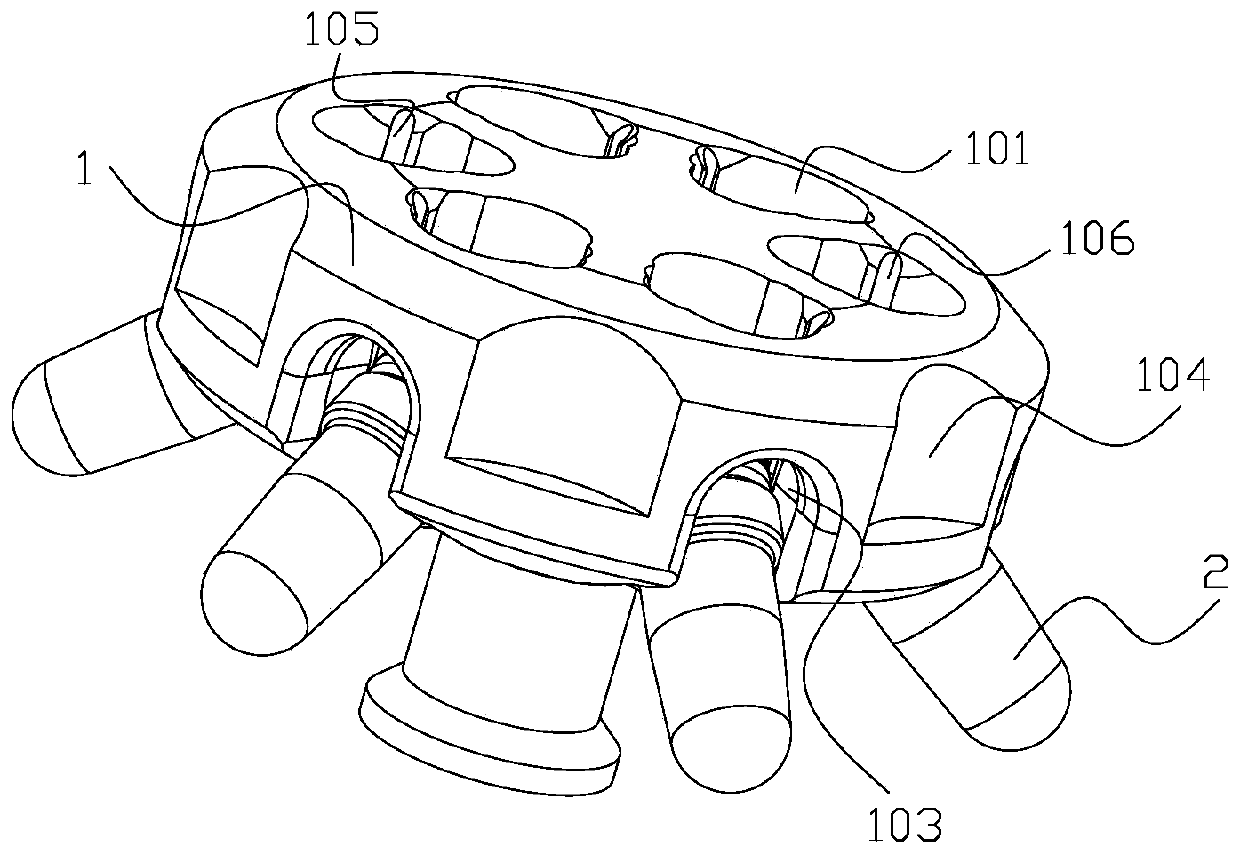

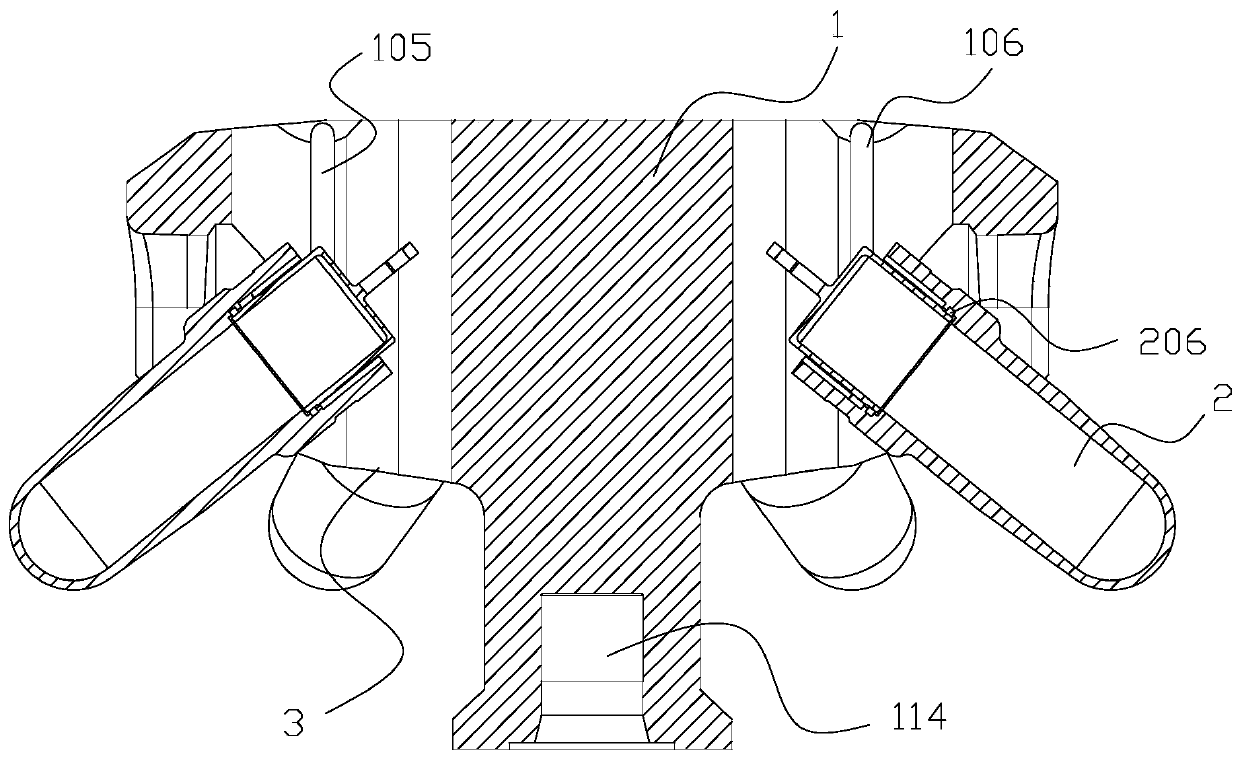

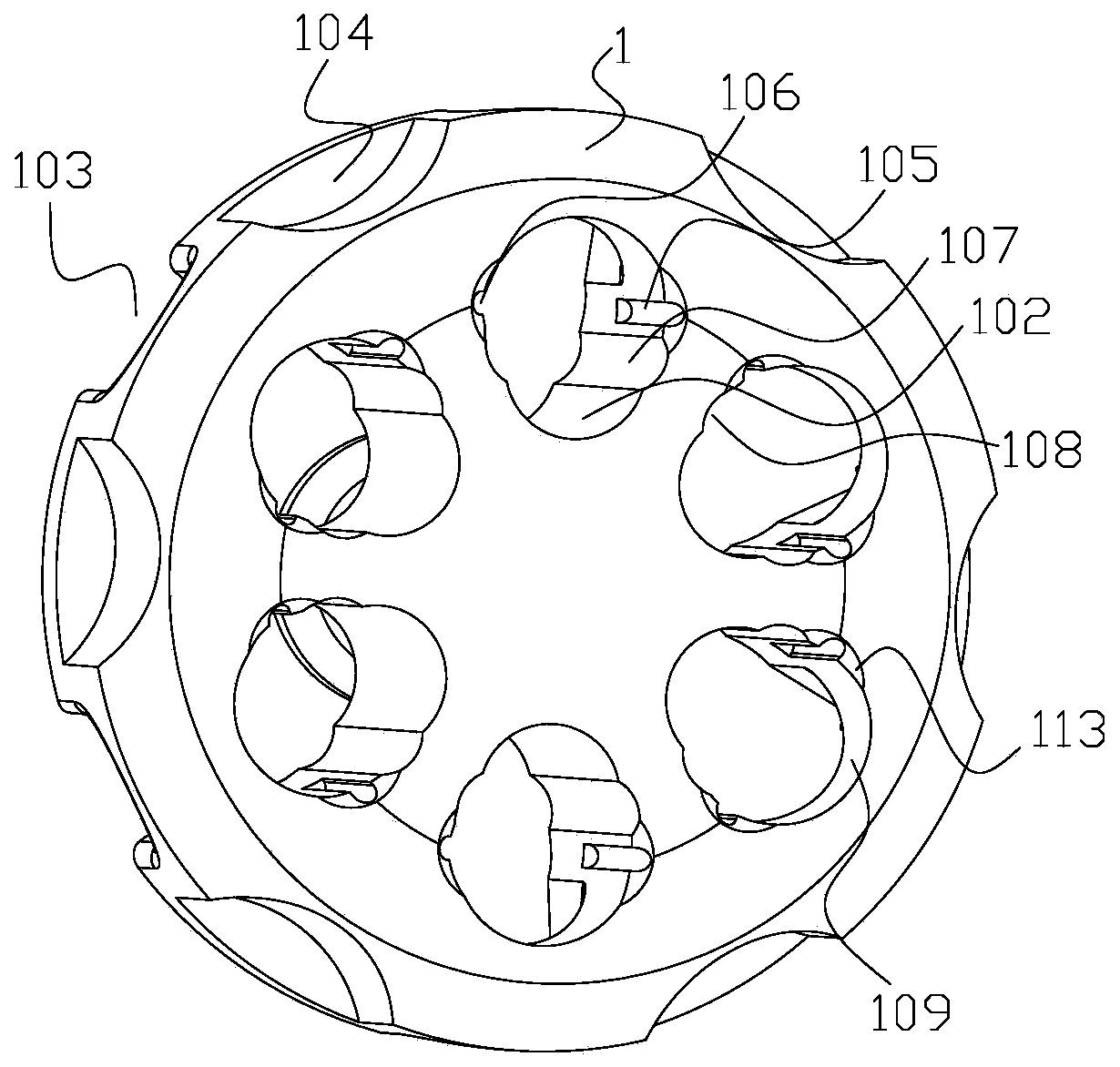

[0025] Such as Figure 1 to Figure 5 Shown, a kind of medical high-speed centrifugal equipment, this equipment comprises a kind of medical high-speed centrifugal rotor. A medical high-speed centrifugal rotor is made of titanium alloy. The rotor includes a centrifugal rotating frame 1 and a hanging cup 2 . The section of the centrifugal rotating frame 1 is T-shaped, and the upper part of the centrifugal rotating frame 1 is in the shape of a round cake. The upper and lower ends of the centrifugal rotating frame 1 are connected with the lower upper end of the centrifugal rotating frame 1 through the transition slope 3 , and the lower part of the centrifugal rotating frame 1 is provided with a shaft matching hole 114 . The top array of the centrifugal rotating frame 1 is provided with a plurality of hanging cup th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com