Liquid-gas separation method

A technology of liquid-gas separation and liquid-gas separator, which is applied in the field of oil drilling, can solve the problems of poor separation effect, difficult gas separation, low efficiency of liquid-gas separation, etc., to facilitate maintenance, promote liquid-gas separation, and enhance centrifugal separation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

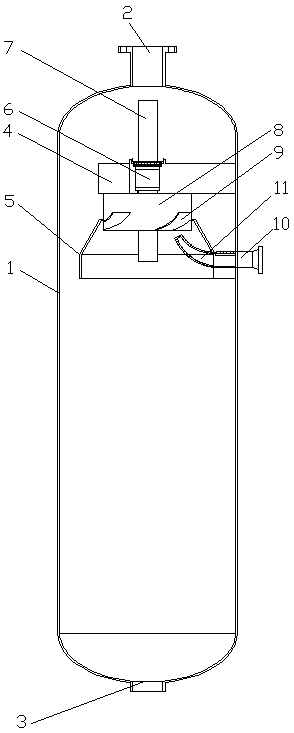

[0048] see figure 1 , a liquid-gas separation method, comprising the following steps:

[0049] a. Spray the gas-containing mud into the rotor of the liquid-gas separator through the inlet elbow 11 of the liquid-gas separator;

[0050] b. The gas-containing mud collides with the blades 9 in the rotor to disperse the gas-containing mud and perform the first liquid-gas separation;

[0051] c. The gas-containing mud pushes the rotor to rotate, and the gas-liquid is stratified under the action of centrifugal force, and the second liquid-gas separation is carried out;

[0052] d. The rotor rotates to throw out the air-containing mud, and evenly sprinkles it on the inner wall of the separation cover 5. The air-containing mud flows downward along the inner wall of the separation cover 5 under the action of gravity, forming an extremely thin cylindrical liquid film, and the air-containing mud The gas escapes from the cylindrical liquid film for the third liquid-gas separation;

[00...

Embodiment 2

[0055] see figure 1 , a liquid-gas separation method, comprising the following steps:

[0056] a. Spray the gas-containing mud into the rotor of the liquid-gas separator through the inlet elbow 11 of the liquid-gas separator;

[0057] b. The gas-containing mud collides with the blades 9 in the rotor to disperse the gas-containing mud and perform the first liquid-gas separation;

[0058] c. The gas-containing mud pushes the rotor to rotate, and the gas-liquid is stratified under the action of centrifugal force, and the second liquid-gas separation is carried out;

[0059] d. The rotor rotates to throw out the air-containing mud, and evenly sprinkles it on the inner wall of the separation cover 5. The air-containing mud flows downward along the inner wall of the separation cover 5 under the action of gravity, forming an extremely thin cylindrical liquid film, and the air-containing mud The gas escapes from the cylindrical liquid film for the third liquid-gas separation;

[00...

Embodiment 3

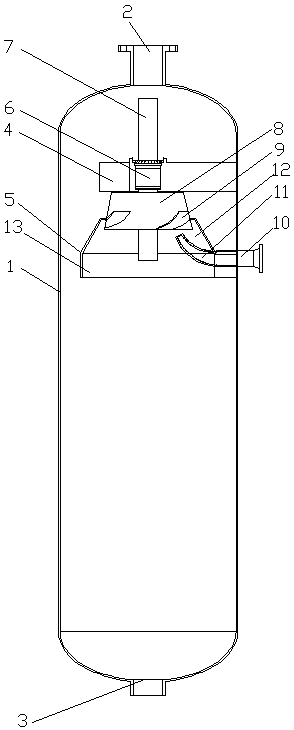

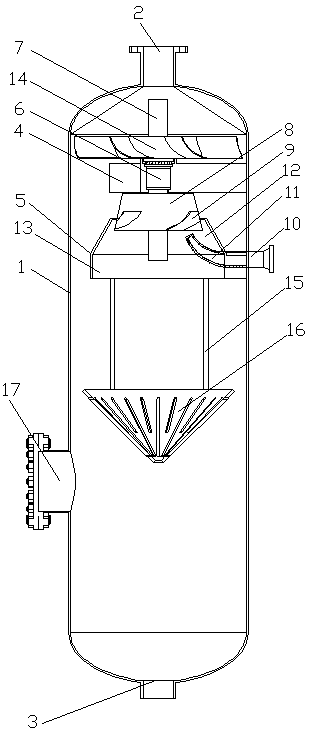

[0064] see figure 2 , a liquid-gas separation method, comprising the following steps:

[0065] a. Spray the gas-containing mud into the rotor of the liquid-gas separator through the inlet elbow 11 of the liquid-gas separator;

[0066] b. The gas-containing mud collides with the blades 9 in the rotor to disperse the gas-containing mud and perform the first liquid-gas separation;

[0067] c. The gas-containing mud pushes the rotor to rotate, and the gas-liquid is stratified under the action of centrifugal force, and the second liquid-gas separation is carried out;

[0068] d. The rotor rotates to throw out the air-containing mud, and evenly sprinkles it on the inner wall of the separation cover 5. The air-containing mud flows downward along the inner wall of the separation cover 5 under the action of gravity, forming an extremely thin cylindrical liquid film, and the air-containing mud The gas escapes from the cylindrical liquid film for the third liquid-gas separation;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com