Permanent magnetic high-gradient comprehensive force field separator with disc structure

A sorting machine and high-gradient technology, applied in high-gradient magnetic separators, magnetic separation, solid separation, etc., can solve the problems of low sorting efficiency, small number of poles in the magnetic process work area, and deterioration of magnetic field distribution characteristics. Achieve the effect of simplifying the mechanical structure of the equipment, reducing the cost and energy consumption, and eliminating the uneven sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

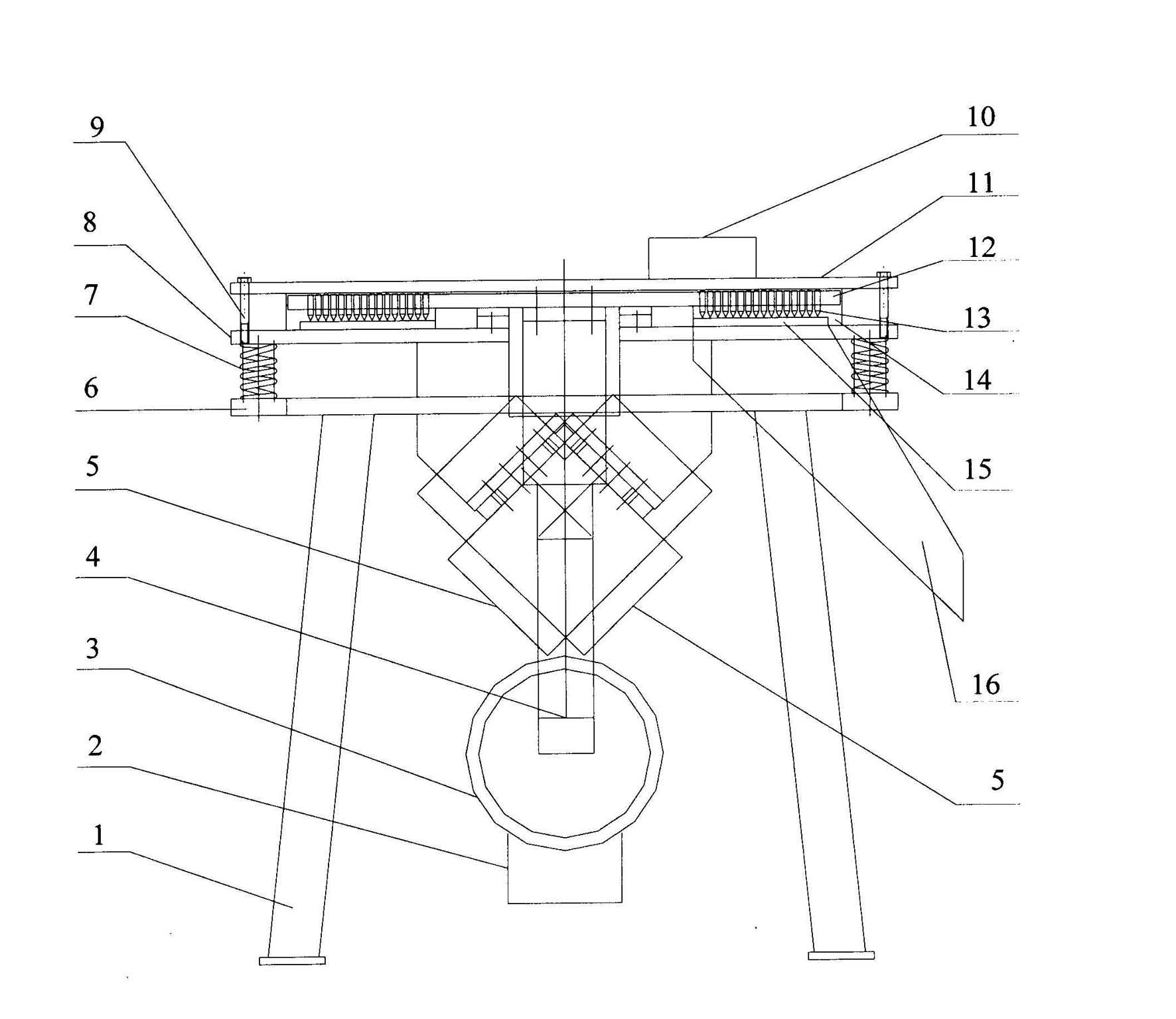

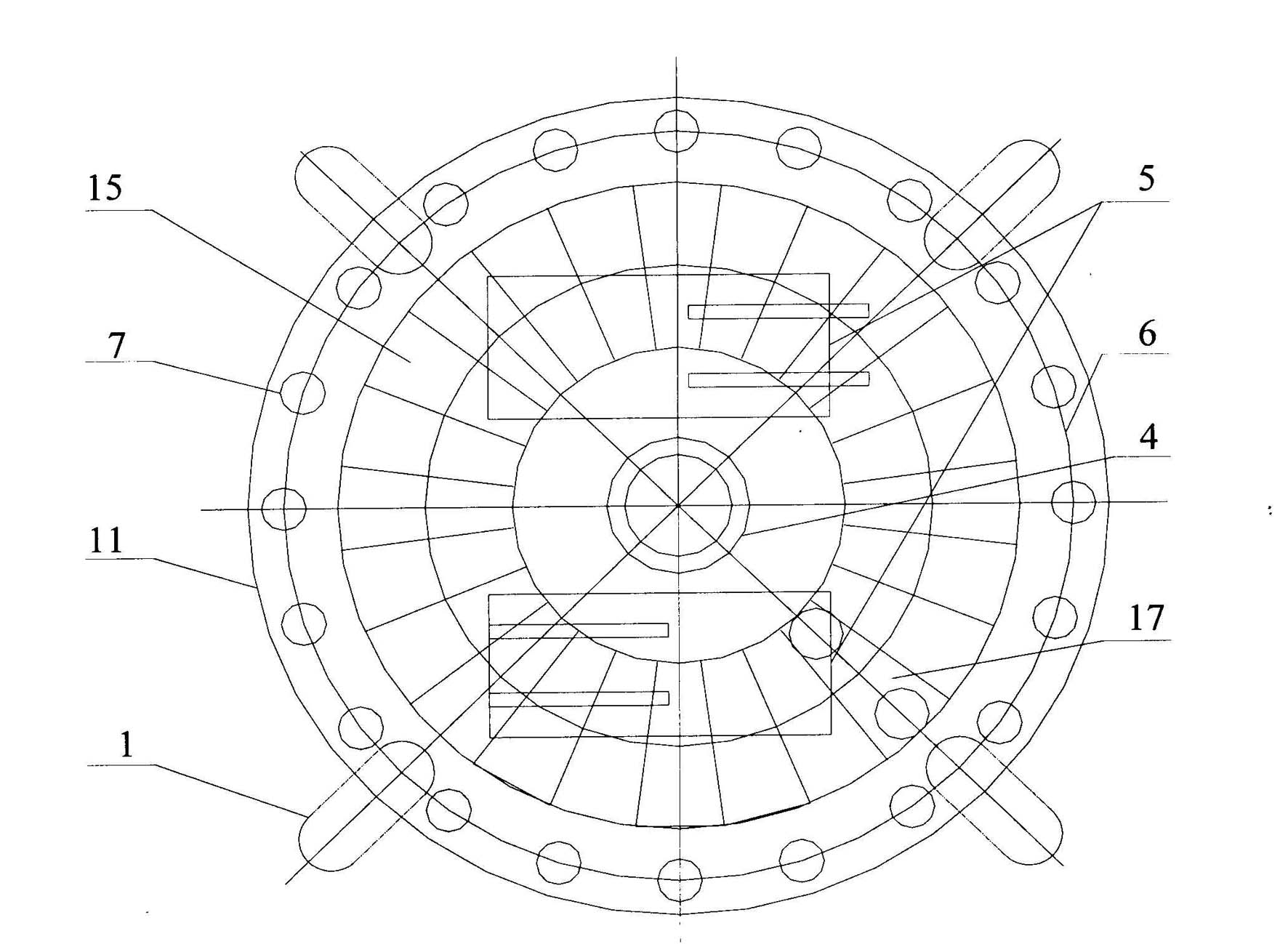

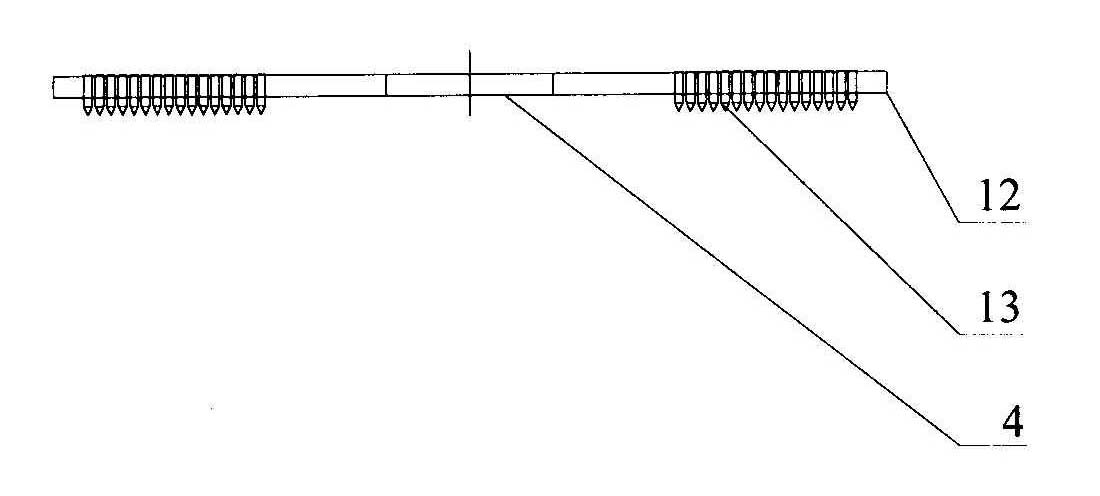

[0034] like figure 1 , figure 2 As shown, the disc structure permanent magnet high-gradient comprehensive force field separator of the present invention comprises a support 1 provided with four support legs, a support substrate 6 of an annular structure arranged on the support in a horizontal manner, and supported by surrounding The multiple groups of shock-absorbing springs 7 arranged on the circumference of the base plate 6 are installed on the disk 8 above the support base plate 6 in a coaxial manner with the support base plate 6, with a gap fit (the effect of the gap fit is to meet the smooth rotation of the magnetic nail rotating disk. need) and are installed on the magnetic gathering nail rotating disk 12 and the top layer of the ring disk 11 above the magnetic disk 8 in a coaxial manner with the magnetic disk 8, and are installed on the magnetic gather...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com