Fully-prefabricated structure and construction method thereof

A technology of prefabricated assembly and prefabricated components, which is applied in the direction of building construction, construction, and building material processing, etc. It can solve problems such as difficult to control the quality of concrete parts, poor waterproof effect at joints of external walls, and difficulty in ensuring the flatness of walls, etc. , to save the cost of maintenance measures, avoid on-site concrete work, and save the effect of plastering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

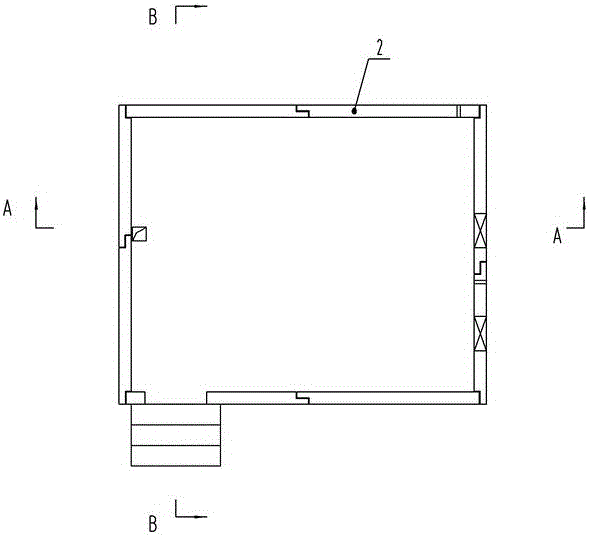

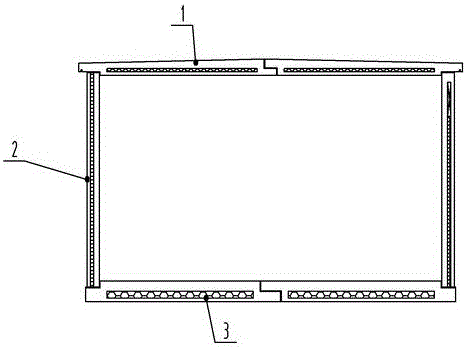

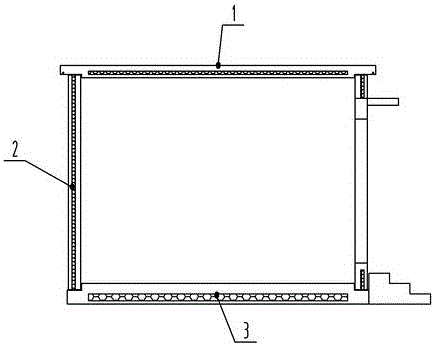

[0031] Embodiment 1: (This embodiment takes a single-story computer room as an example for illustration)

[0032] see Figure 1-3 , in the figure, the fully prefabricated assembly structure of the present invention is composed of twelve prefabricated components, including two top panels 1, eight wall panels 2, and two bottom panels 3, and each prefabricated component is reserved and pre-embedded with bolts according to the drawing design , Steel gaskets, rings, drip tanks, etc. Among them, the prefabricated wall panels, roof panels and bottom panels are respectively spliced by two pieces. An assembly gap of 10 mm is reserved between components of the assembly structure. The assembly connection between the components includes the parallel connection of the concrete prefabricated components and the connection between the prefabricated wall panels and the vertical joints between the top and bottom panels. Among them, the parallel connection of concrete prefabricated componen...

Embodiment 2

[0044] The present invention also provides a construction method for a fully prefabricated assembly structure as described in Embodiment 1, wherein the prefabricated components are poured and cured in the factory, and after meeting the lifting strength requirements, the prefabricated components are transported to the site for assembly construction, specifically The construction process is as follows: first fix the water-expandable rubber water-stop strip at the L-shaped interface of the prefabricated component, and then hoist the bottom plate, wall plate and roof plate in sequence according to the construction plan, and reserve a 10mm assembly gap between the components; After being fixed with tension bolts between the two sides, apply concrete sealant at the joints of the inner and outer sides first, and then pour cement-based grouting material from the top, so that the two adjacent prefabricated components form an integral structure; the joint between the wall and the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com