Connecting structure for prefabricated regenerated block concrete beam and construction method thereof

A technology for concrete beams and prefabricated beams, which is applied to building structures, joists, girders, etc., can solve problems such as large environmental impact, slow construction speed, adverse effects on concrete pouring quality, etc. The effect of solving the quality problem of concrete pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

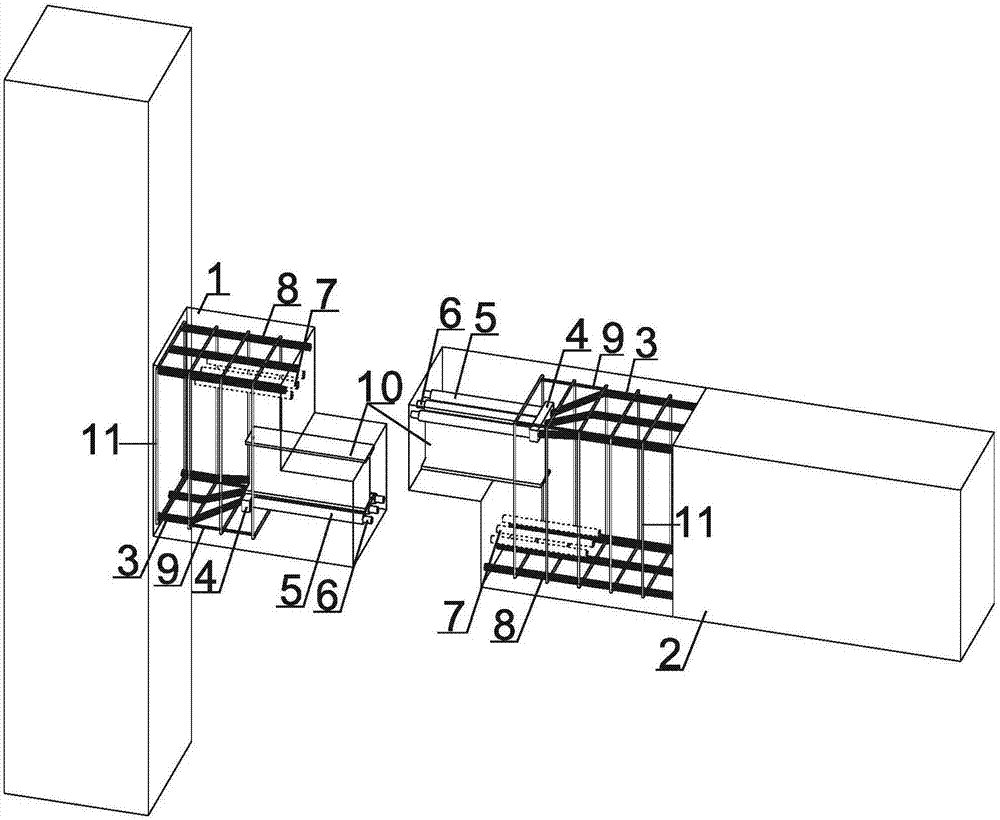

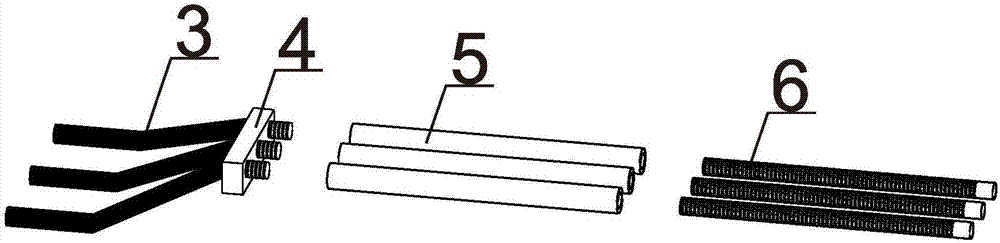

[0041] like figure 1As shown, a connection structure of prefabricated recycled block concrete beams, including corbels 1 prefabricated simultaneously with columns, prefabricated beams 2 with notches at the ends, positioning plates with holes 4, vertical bars 9, stirrups 11, common Longitudinal bars 8 , bent longitudinal bars 3 , steel sleeves with internal threads 5 , steel bar bars with external threads 6 , shear steel 10 and axial tunnels 7 .

[0042] The size of the complete section of the corbel 1 prefabricated at the same time as the column is 350 mm × 600 mm, the size of the complete section of the prefabricated beam 2 with notches at the end is 350 mm × 600 mm, and the diameter of the vertical reinforcement 9 and the stirrup 11 is 10 mm 1. The diameters of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com