Integrally fabricated box-shaped multi-ribbed composite floor

A monolithic and floor-slab technology, which is applied to floors, building components, buildings, etc., can solve the problems of low industrial production level, low prefabrication rate, labor and time-consuming problems of hollow ribbed floors, etc., and achieve the reduction of poor sound insulation performance, hollow The effect of high efficiency and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

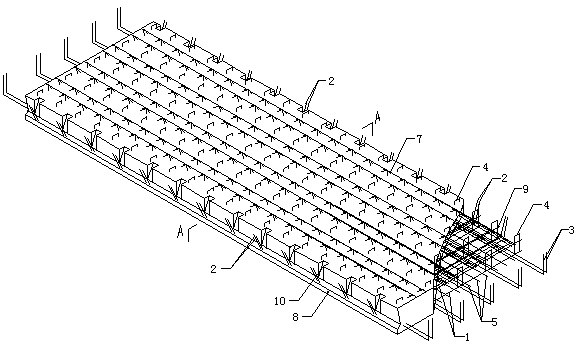

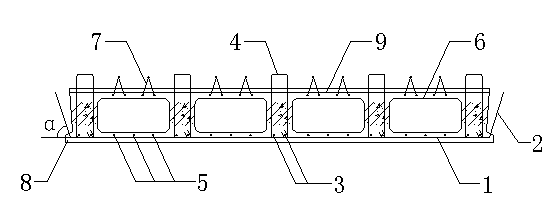

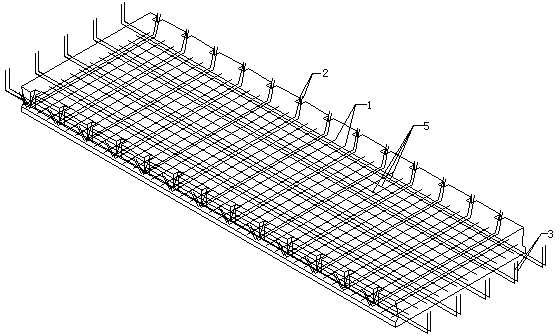

[0042] From Figure 1-5 It can be seen from the figure that: an assembled integral dense-ribbed box-shaped composite floor (referred to as composite floor), is characterized in that: the assembled integral dense-ribbed box-shaped composite floor is mainly composed of the bottom horizontal reinforcement 1, the bottom connection reinforcement 2, The rib beam lower longitudinal reinforcement 3, the rib beam stirrup 4, the bottom longitudinal reinforcement 5, the formwork 6, the truss reinforcement 7, the flange 8, the top horizontal reinforcement 9, the wedge-shaped groove 10 and the concrete layer (that is, the concrete slab), The bottom connecting reinforcing bars 2 are evenly laid at intervals from left to right according to the design, and the connecting reinforcing bars 2 at the bottom are double reinforcing bars in front and rear directions, and the front end and rear end sections of each connecting reinforcing bar 2 are symmetrically respectively The angle α is bent in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com