Lightweight fabricated shear wall structure

A prefabricated shear wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult structure of prefabricated shear walls, producing a lot of construction waste, and self-heavy wall components. The effect of lifting efficiency and safety, reducing the amount of reinforcement works, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

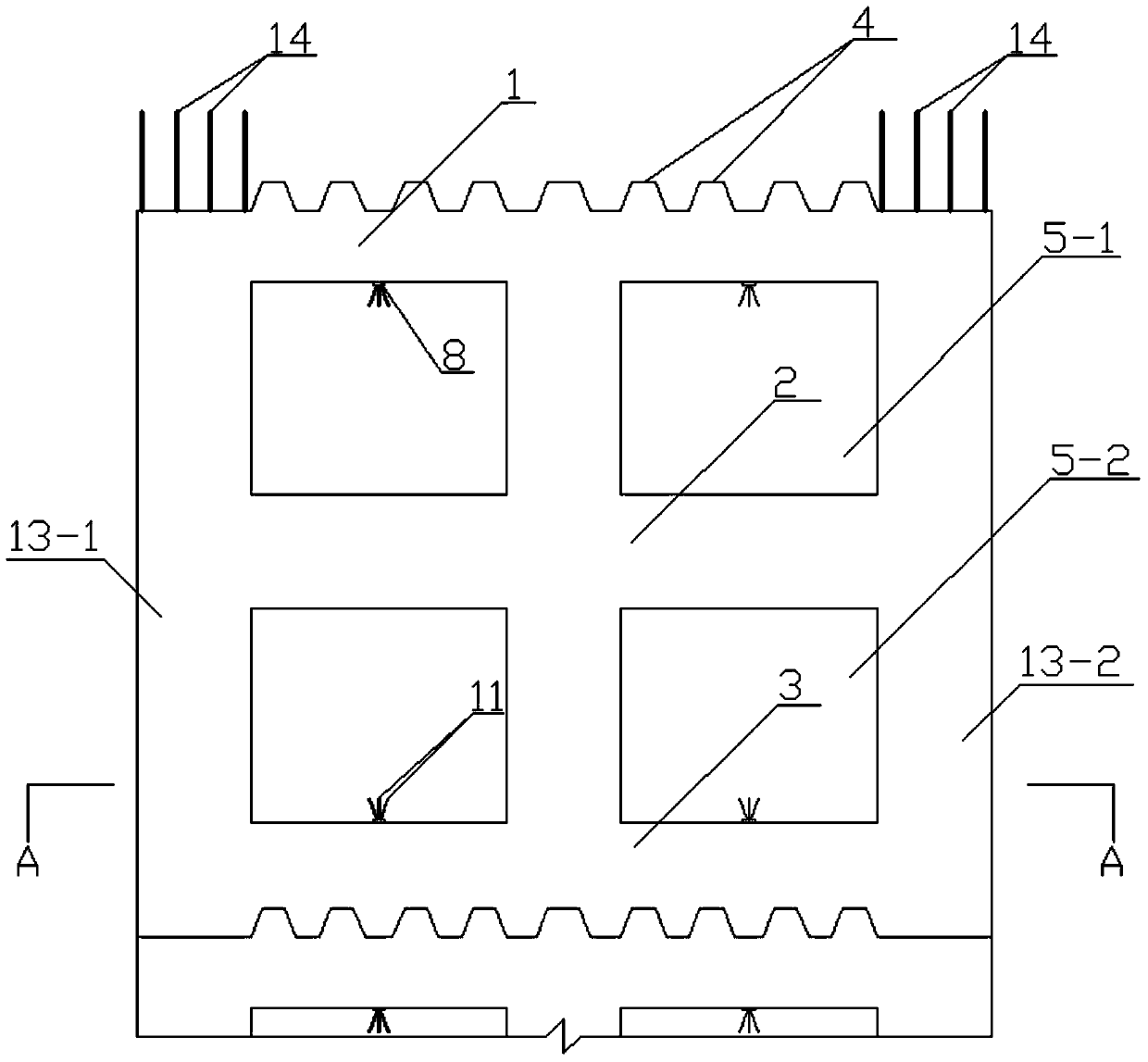

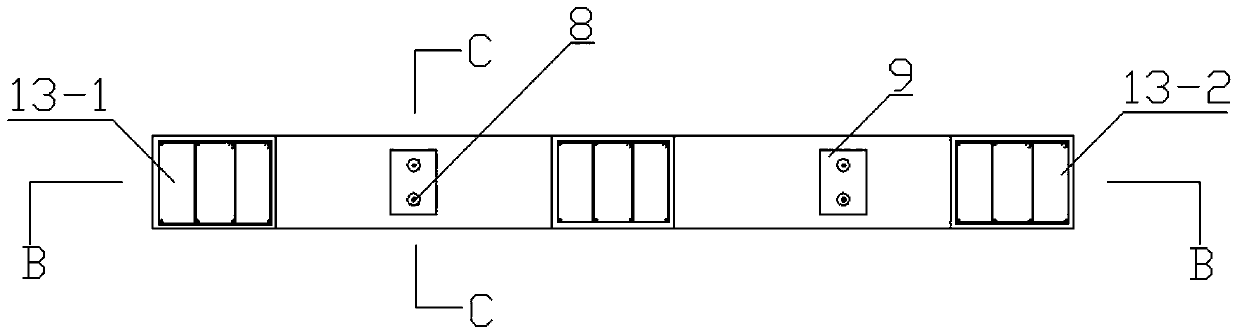

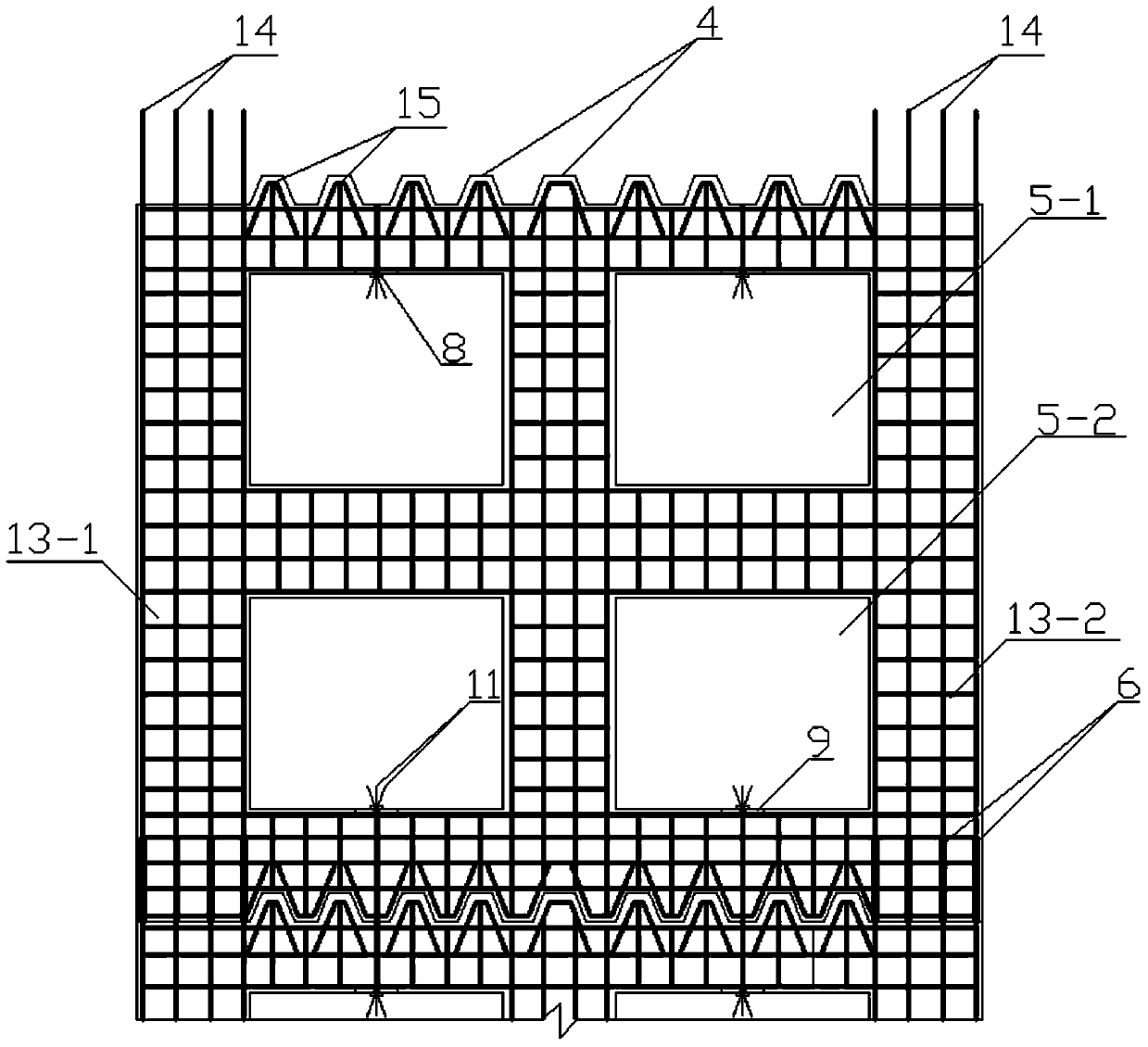

[0021] see Figure 1 to Figure 6 , a light prefabricated shear wall structure, which is formed by assembling a plurality of reinforced concrete wall panels, and the wall panels are provided with openings; the openings divide the wall panels into upper beams 1, lower beams 3, Left concealed column 13-1 and right concealed column 13-2, described left concealed column 13-1 and described right concealed column 13-2 are all equipped with concealed column vertical reinforcement 14; The wall panels are connected by the vertical steel bars 14 of the concealed columns and the prestressed steel strands 11, and the prestressed steel strands 11 are connected to the bottom surface of the upper beam at the opening of the lower wall panel and the upper beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com