Fixed telescopic type crevasse plugging device and method

A plugging device and telescopic technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of not considering the size of the crevasse, the depth of the crevasse, and the difficulty of use, and achieve rapid and efficient deployment, simple structure, and low failure rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

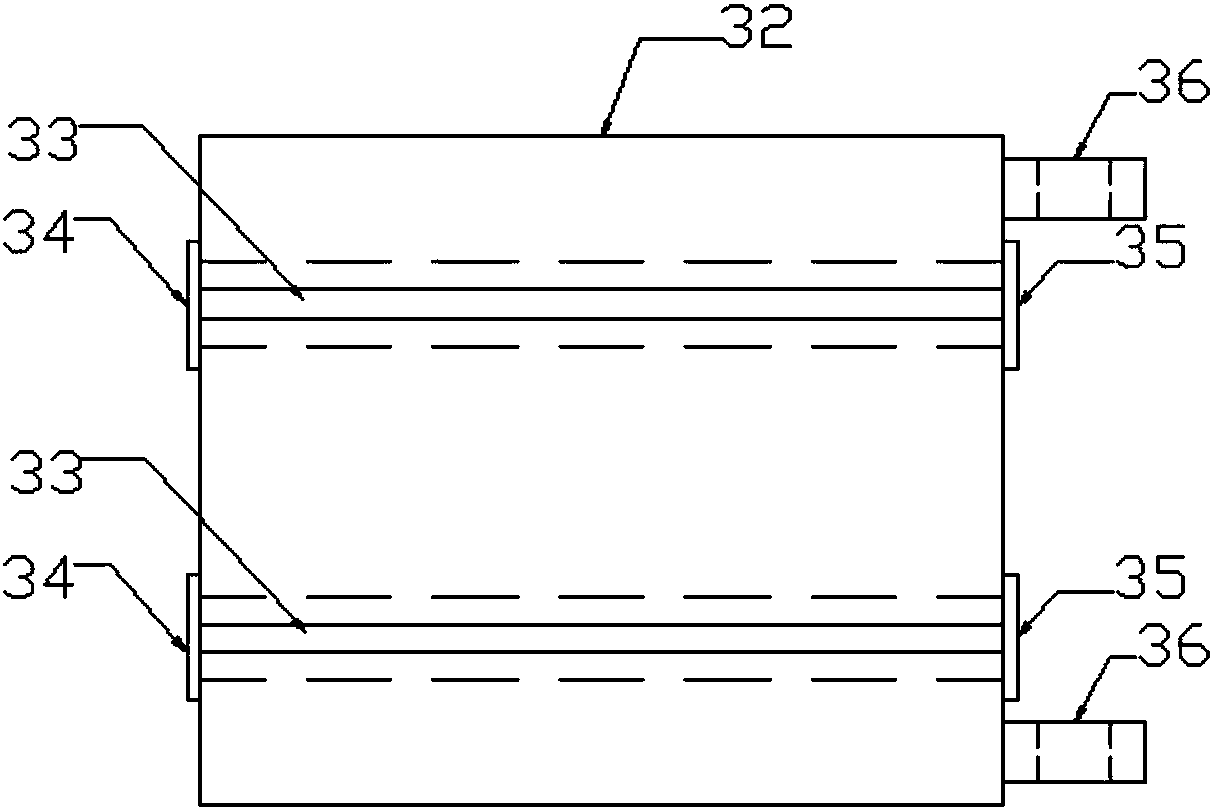

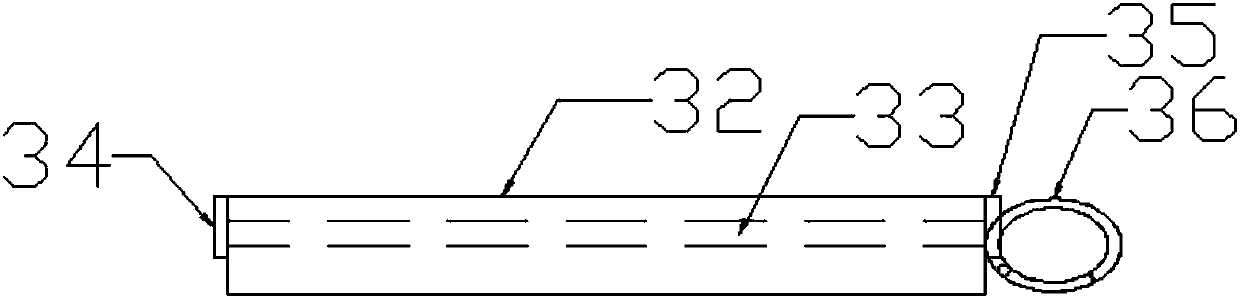

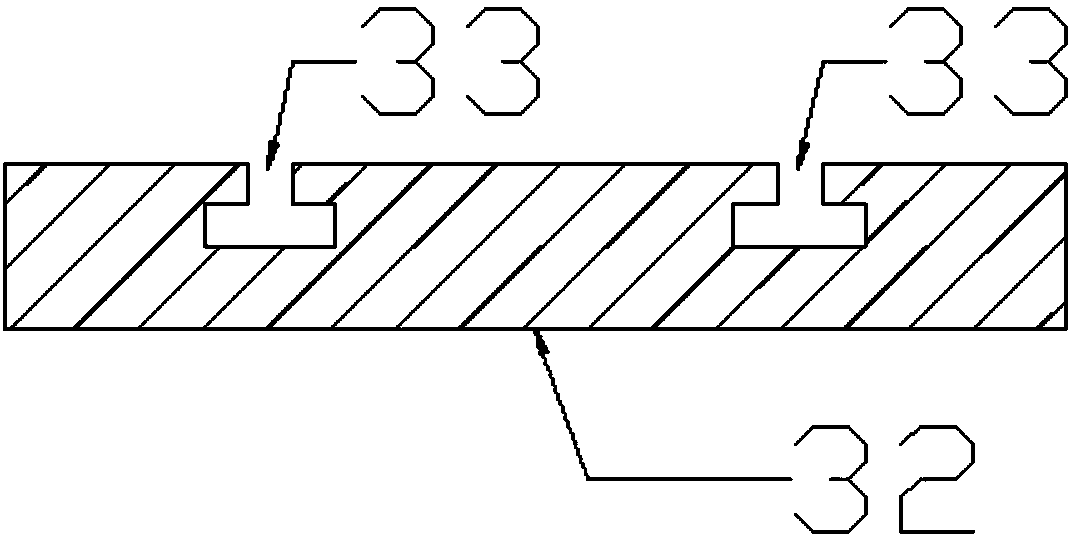

[0139] Such as Figure 1-3 Shown is a foundation baffle 31 of another embodiment of the present invention. The base baffle 31 includes a base baffle main body 32, at least one base baffle slideway 33, at least one base baffle stopper (including the base baffle front stopper 34 and the base baffle rear stopper 35), at least A base baffle hook 36.

[0140] The base baffle body 32 is a rectangular plate with a thickness of more than 1 millimeter, a length of more than 0.5 meters, and a width of more than 5 centimeters; preferably, the thickness is 10 millimeters, the length is 3 meters, and the width is 2 meters.

[0141] At least one base baffle slideway 33 parallel to the long side and above is fixedly arranged on the top of the base baffle main body 32; The plate slideway 33 runs through the base baffle main body 32; the cross-section of the base baffle slideway 33 main body includes one of the following shapes: inverted "T" shape, triangle, trapezoid, regular polygon; prefe...

Embodiment example 2

[0154] Such as Figure 4-6 Shown is the unit baffle 37 of the intercepting baffle group 03 according to another embodiment of the present invention. The unit baffle 37 includes: a unit baffle main body 38, at least one unit baffle slideway 39, at least one unit baffle stopper (including unit baffle front stopper 40 and unit baffle rear stopper 41), At least one unit shutter sliding member 42 .

[0155] The unit baffle body 38 is a rectangular plate with a thickness of more than 1 millimeter, a length of more than 0.5 meters, and a width of more than 5 centimeters; preferably, the thickness is 10 millimeters, the length is 3 meters, and the width is 2 meters.

[0156] At least one unit baffle slideway 39 parallel to the long side and parallel to the top is fixedly arranged on the top of the unit baffle main body 38; the unit baffle slideway 39 is used for sliding parts used in conjunction with it; The plate slideway 39 runs through the unit baffle main body 38; the cross sect...

Embodiment example 3

[0171] Such as Figure 7-9 Shown is the tail plate 43 of the intercepting baffle group 03 of another embodiment of the present invention. Tail plate 43 comprises: tail plate main body 44, tail plate sliding part 45;

[0172] The tail plate main body 44 is a rectangular plate with a thickness of more than 1 millimeter, a length of more than 0.5 meters, and a width of more than 5 centimeters; preferably, the thickness is 10 millimeters, the length is 2.76 meters, and the width is 2 meters.

[0173] The rear end below the tailgate main body 44 is fixedly arranged with at least one tailgate sliding part 45;

[0174] Preferably, the relative position, size, structure, shape, number, etc. of the tailgate sliding part 45 and the unit baffle sliding part 42 in the seventh embodiment are the same.

[0175] Optionally, reinforcing ribs are fixedly arranged on the main body 44 of the tail plate to increase the compressive capacity of the tail plate 43; preferably, 19 reinforcing ribs a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com