Self-heating curly asphalt blanket and preparation and construction methods thereof

A self-heating, curling technology, which is applied to the pavement paved with prefabricated blocks, roads, road repairs, etc., to achieve the effect of increasing temperature, improving bonding effect, and sufficient heating reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

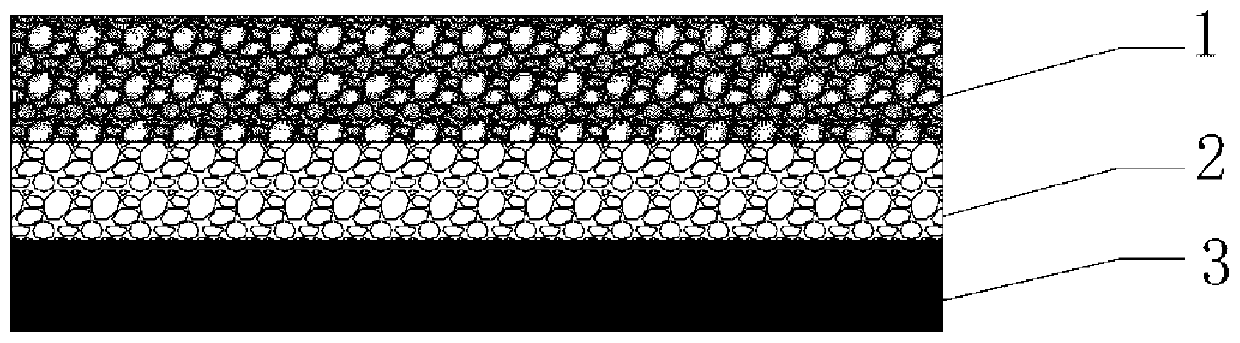

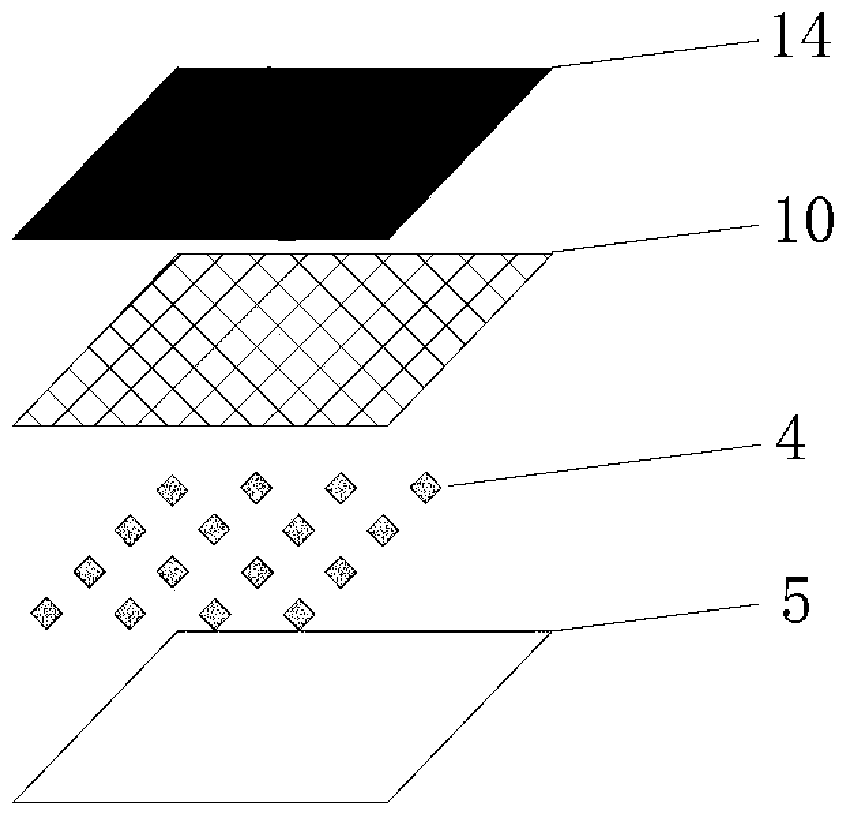

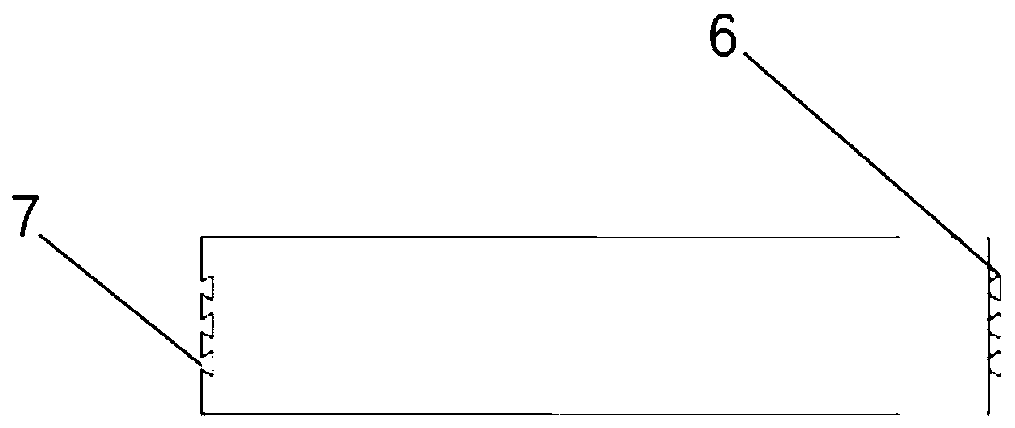

[0038] Refer to the accompanying drawings, a self-heating curly asphalt blanket, including asphalt mixture layer 1, middle layer 2, self-heating adhesive layer 3, asphalt mixture layer 1, intermediate layer 2, self-heating adhesive layer 3 from top to The asphalt blanket is laid in sequence, the asphalt mixture layer 1 is composed of modified asphalt, coarse aggregate, fine aggregate and filler, and its thickness is 20-30mm, and the middle layer 2 is composed of fine aggregate and modified asphalt. Its thickness is 5-10mm. The self-heating adhesive layer 3 is composed of a heating pack 4, a self-heating adhesive layer modified asphalt 14, an isolation film 5 and a geogrid 10. Its thickness is 5-10mm. The heating pack 4 generates heat. The formulation of the agent is: reduced iron powder 20-40%, aluminum powder 10-50%, calcium oxide 5-25%, sodium carbonate 5-25%, activated carbon 3-12%, magnesium powder 1-3%, trihydrate acetic acid Sodium crystal 1-5%, sodium chloride 1-5%, roa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com