Prefabricated compound integrated wall board and application thereof

A wallboard and function technology, which is applied in the field of prefabricated composite wallboards, can solve the problems of inconvenient wallboard construction, thermal bridges at beams and columns, and wall cracking, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

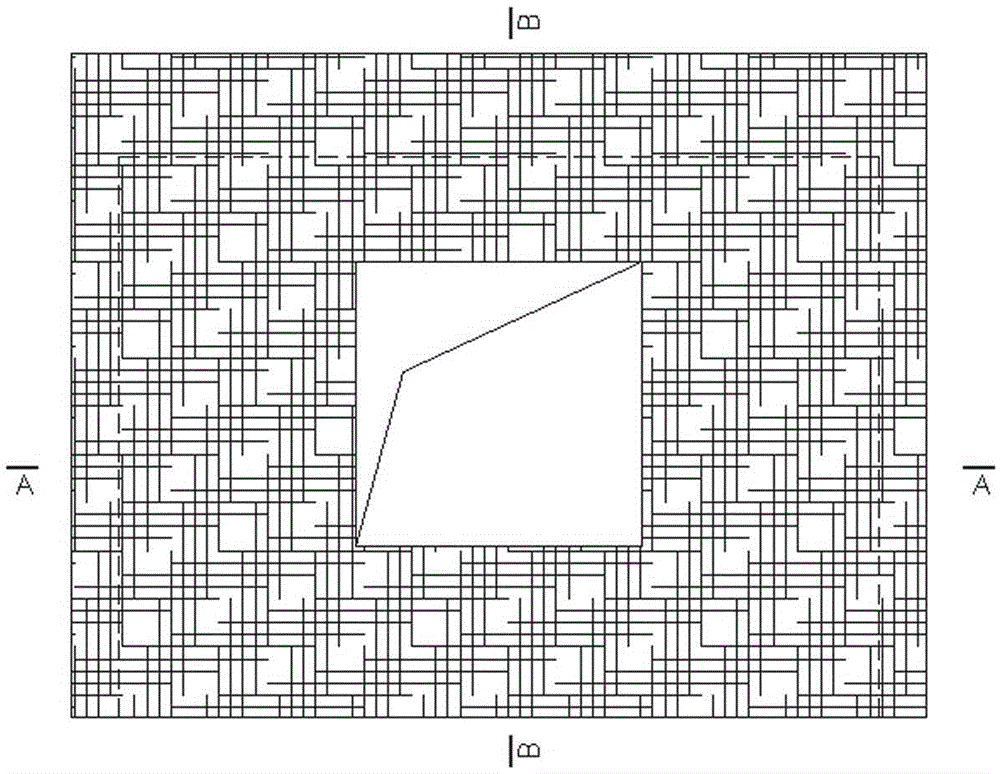

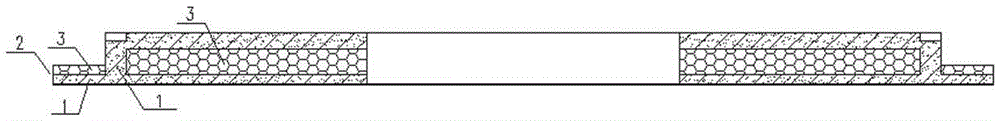

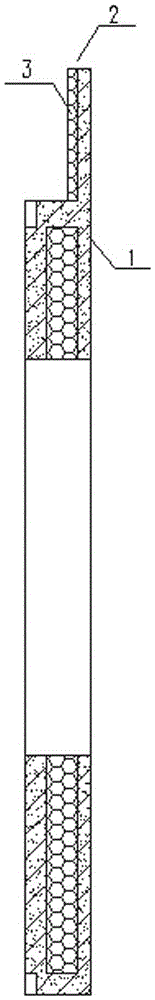

[0029] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] Please combine Figure 1-Figure 4 As shown, a prefabricated composite wall panel of the present invention has overhanging flanges 2 on both sides and upper ends for aligning beams 9 and columns 8 (especially fabricated frame columns and steel columns) Wrapping is carried out to avoid generating thermal bridges at the beams 9 and columns 8 of the frame structure, wherein the overhang of the flanges at both ends is 1 / 2 of the column width; the overhang of the upper flange is equal to the beam height. The prefabricated composite whole wall panel includes the inner and outer concrete layers 1 and the middle insulation layer 3 at the non-flange 2, and the prefabricated composite whole wall panel includes the outer concrete layer 1 and the inner insulation layer 3 at the flange 2 . The insulation layer 3 is made of polystyrene boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com