Steel pipe high strength concrete column reinforcing joint and method for manufacturing same

A high-strength concrete, beam-column connection technology, applied in columns, piers, pillars, etc., can solve the problems of difficult welding quality assurance, inconvenient construction, large workload, etc. The effect of seismic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

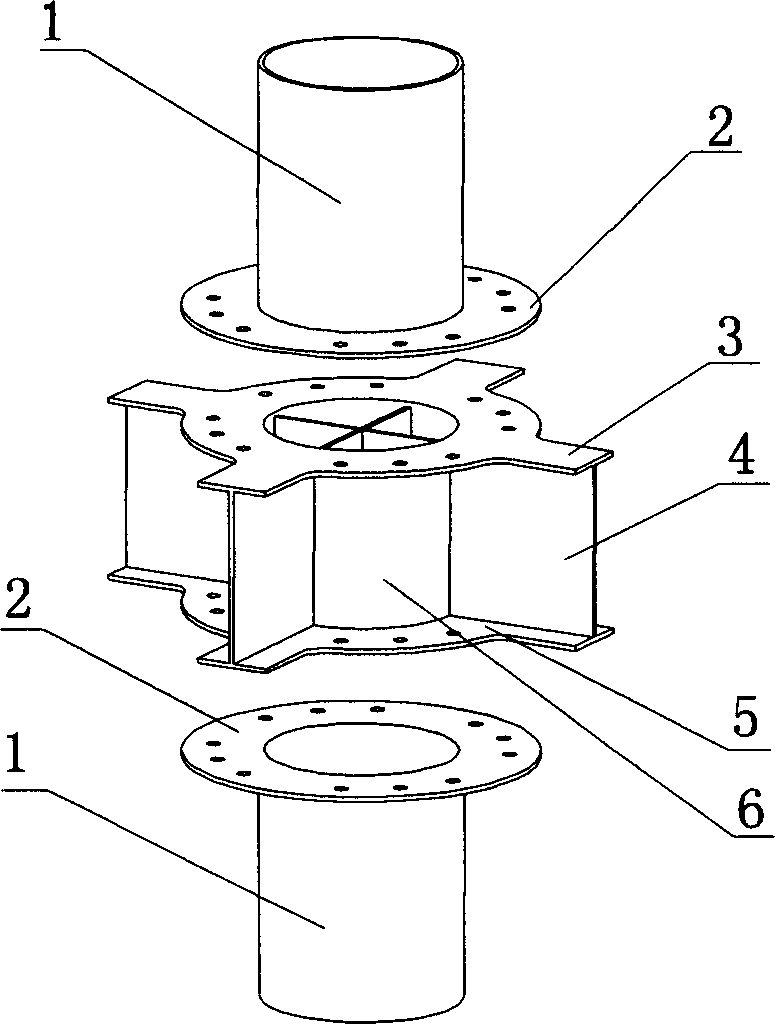

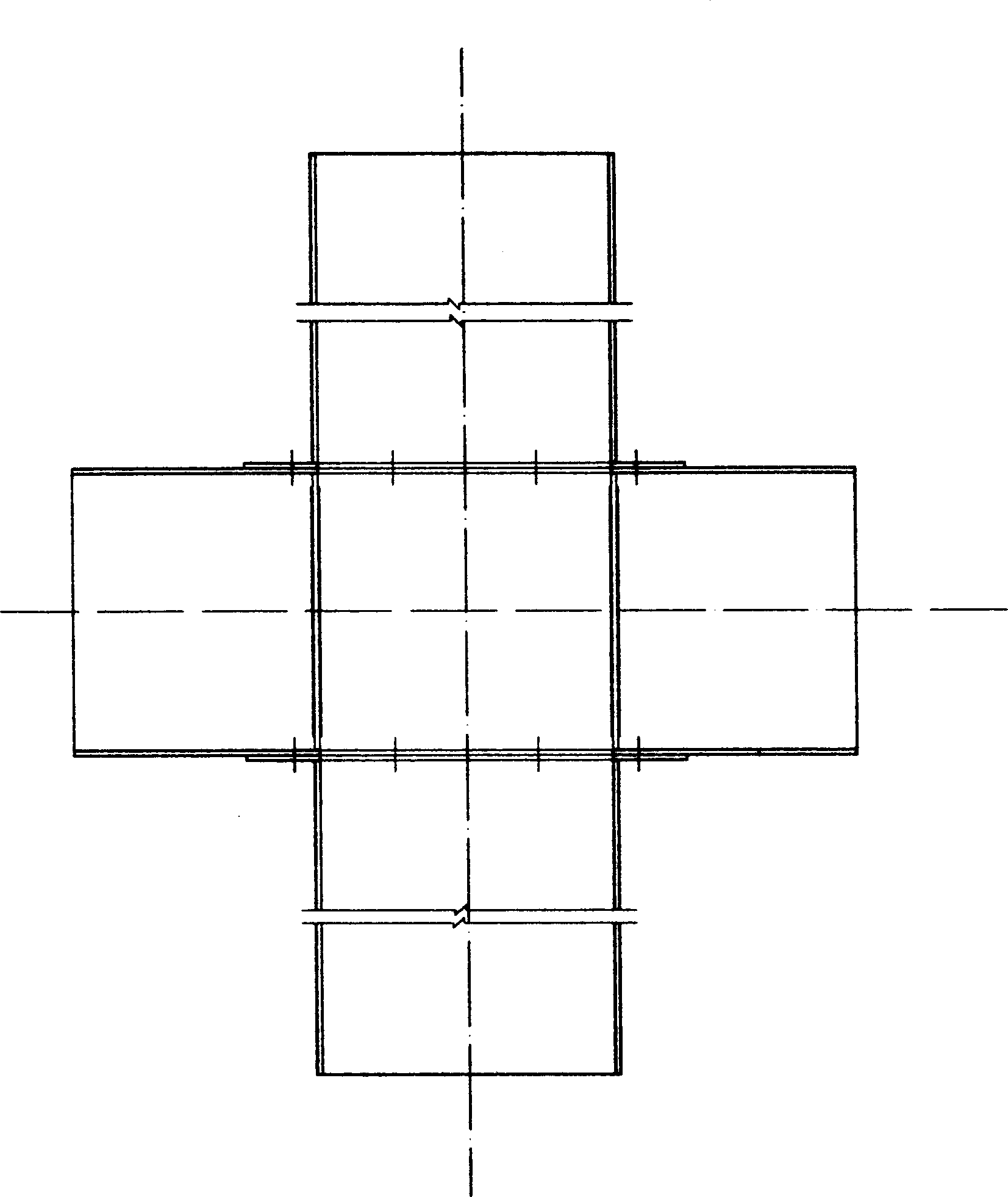

[0015] according to figure 1 As shown, the lengths of the two sections made of steel plates are h 1 and h 2 The steel pipe 6 of the node section and the steel pipe 1 of the column body section, where h 1 Equal to the beam height h of the concrete beam at the joint section b The remaining height after subtracting the thickness of the upper and lower concrete protective layers, h 2 Equal to floor height h minus h 1 remaining height; press Figure 4 with Figure 5 As shown, the flange ring 2, the pull ring 3 and the pressure ring 5 are cut out on a steel plate, and the flange ring 2 is stacked with the pull ring 3 and the pressure ring 5 to drill out Figure 4 with Figure 5 Bolt holes shown; press figure 1 As shown, the "ten"-shaped through-heart web 4 is made of a steel plate; the node segment steel pipe 6 is as figure 1 Cut the four sides as shown; weld the steel pipe 6 of the node section with the "ten"-shaped piercing web 4; respectively weld the pull ring 3 and the...

Embodiment 2

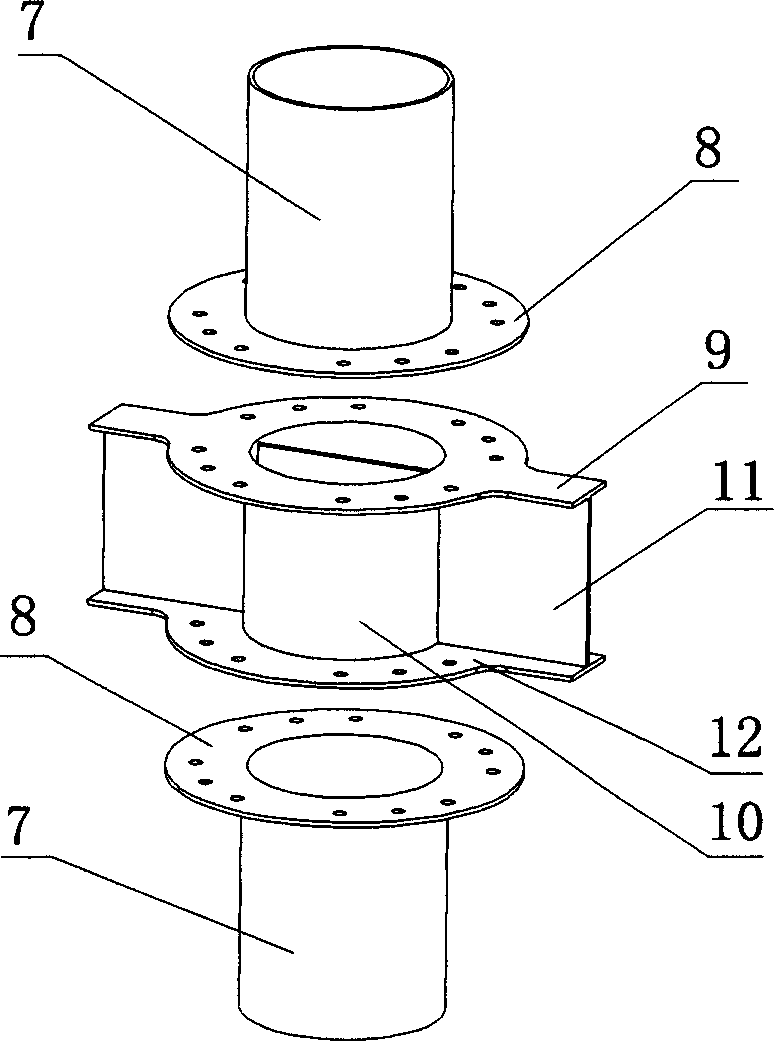

[0017] according to figure 2 As shown, two sections of length h are made with spiral coiled tube 1 and h 2 The steel pipe 10 of the node section and the steel pipe 7 of the column body section, where h 1 Equal to the beam height h of the concrete beam at the joint section b The remaining height after subtracting the thickness of the upper and lower concrete protective layers, h 2 Equal to floor height h minus h 1 the remaining height; press Figure 6 with Figure 4 As shown, the pull ring 9, the pressure ring 12 and the flange ring 8 are cut out on a steel plate, and the flange ring 8 is stacked with the pull ring 9 and the pressure ring 12 to drill out such as Figure 4 with Figure 6 Bolt holes shown; press figure 2 As shown, make a "one"-shaped through-heart web 11 with a steel plate; figure 2 Cut the two sides as shown; weld the steel pipe 10 of the node section with the "one"-shaped through-heart web 11; weld the pull ring 9 and the compression ring 12 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com