Waterproof rotary driving device

A technology of slewing drive and slewing bearing, applied in transmission parts, engine components, engine sealing, etc., can solve problems such as poor sealing and waterproof performance, and achieve the effect of convenient maintenance, creativity and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

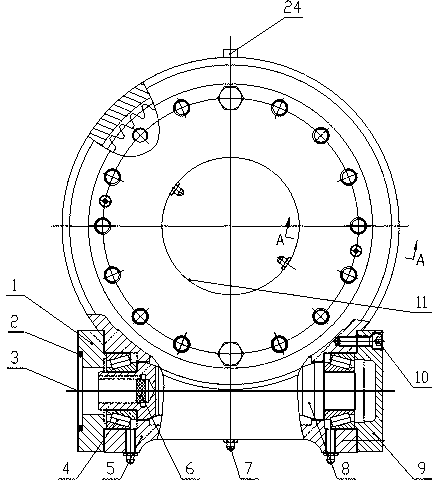

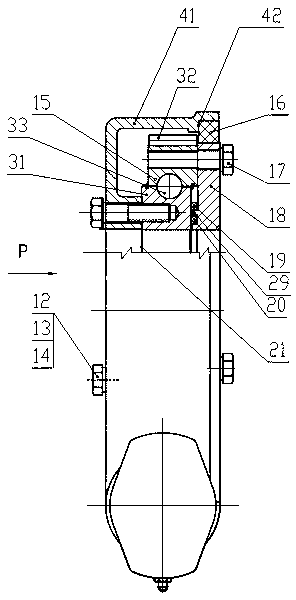

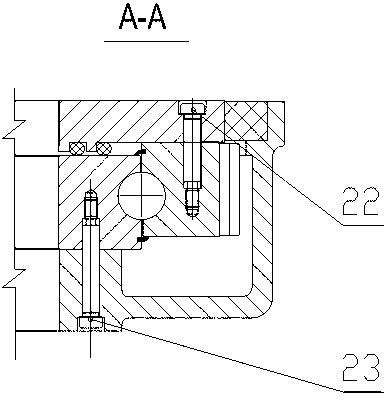

[0021] The waterproof slewing drive device shown in the figure includes a base 5, a slewing bearing 15, and a worm 8. The base 5 is formed by precision casting from two parts: the shaft shell and the seat ring 41. The axis line of the shaft shell and the seat ring The axis lines of 41 are perpendicular to each other in space, the worm 8 is installed in the shaft housing of the base 5, and the slewing bearing 15 includes an inner ring 31, an outer ring gear 32 and a ball 33 embedded in the inner ring and the outer ring gear. The ring gear 32 is provided with a number of mounting screw holes, the inner ring 31 is fixed above the seat ring of the base 5, the outer ring gear 32 is engaged with the worm 8, and the top plate 18 is provided with a channel corresponding to the mounting screw holes of the outer ring gear 32. hole, the top plate 18 is installed above the outer gear ring 32 and the inner ring 31, a lip seal 16 is installed between the outer gear ring 32 and the seat ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com