Machine room hoist rope hole plastic waterproof platform

A technology of traction rope and waterproof platform, applied in the field of elevators, can solve the problems of small construction space of waterproof platform, inconvenient installation and construction, no way to predict in advance, etc., and achieves the effect of reducing construction difficulty and facilitating wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

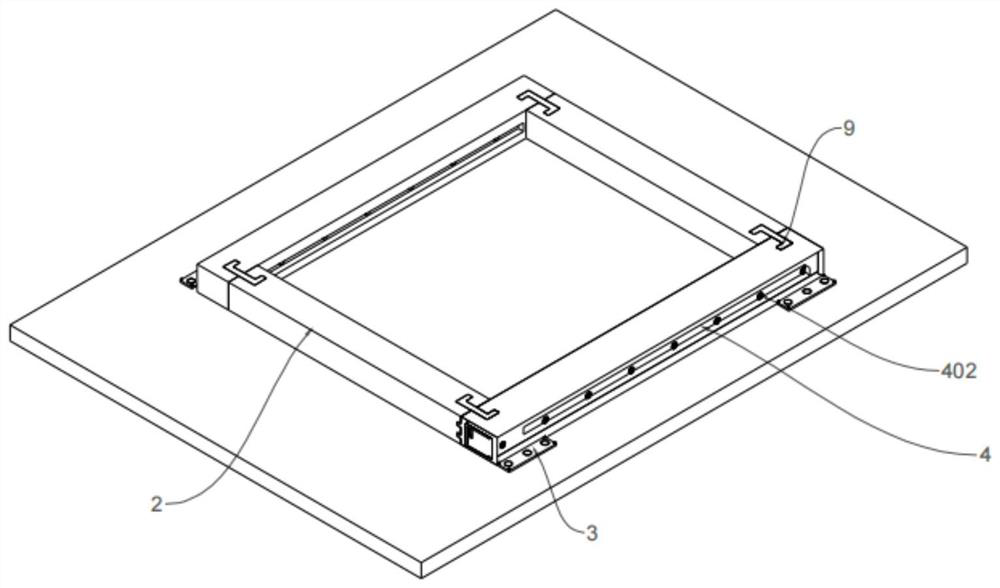

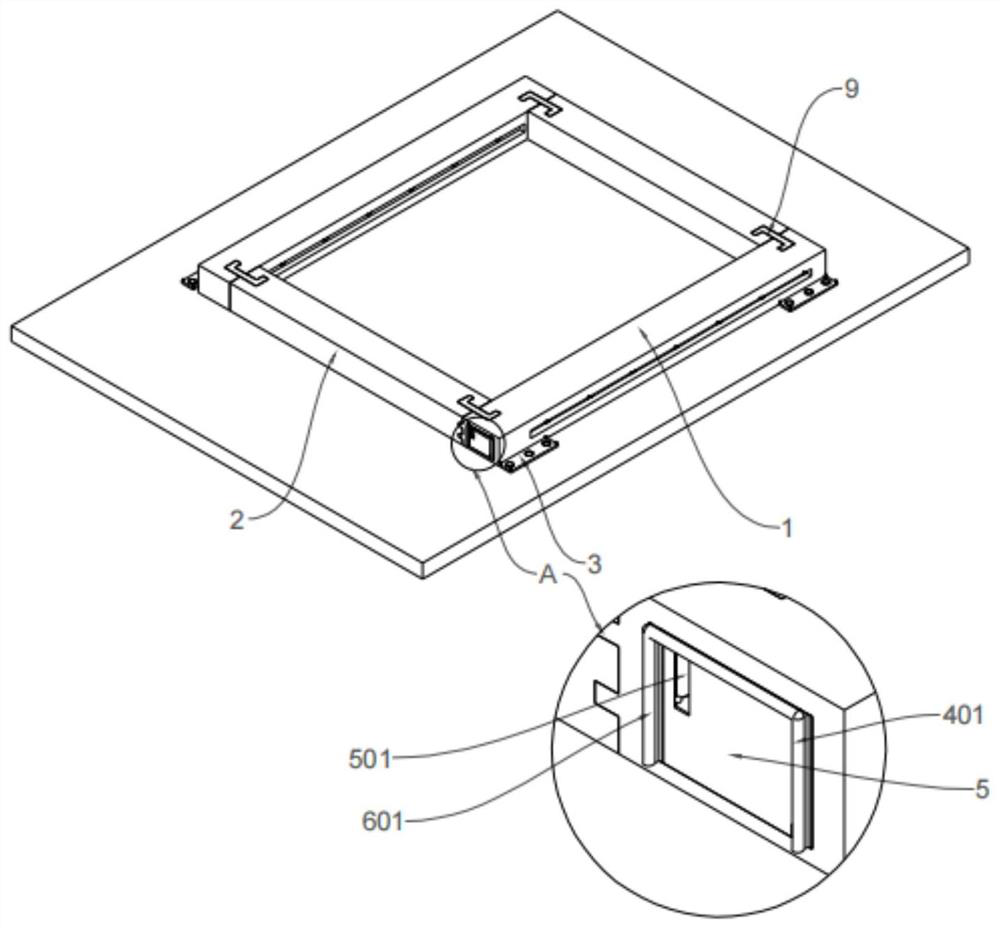

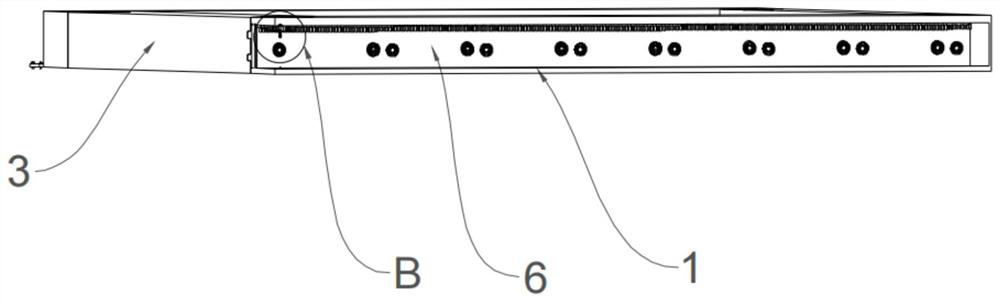

[0034] as attached figure 1 to attach Figure 9As shown: the present invention provides a plastic waterproof table with traction rope holes in a machine room, including a main table 1; Connect the fixing part 3, the front and rear ends between the two groups of main platforms 1 are fixedly connected to the auxiliary platform 2, and the internal activities of the main platform 1 are connected to the linkage plate 4 and the active plate 6, and one end of the main platform 1 is fixedly connected to the cover plate 5, The other end is in a closed state, the internal activity of the main platform 1 is engaged with the locking part 7, and the inner top surface of the main platform 1 is fixedly equipped with an unlocking part 8;

[0035] The auxiliary platform 2 is provided with two groups and forms a rectangular structure together with the two groups of the main platform 1, and the top surface of the connection between the auxiliary platform 2 and the main platform 1 is fixedly cla...

Embodiment 2

[0047] When the device is in use, the operator finds that since the elevator machine room is located on the top of the floor, a large area of water will enter the elevator machine room. To remind, so improve according to the method described in this embodiment.

[0048] The main platform 1 is fixedly installed on the ground of the computer room. The main platform 1 includes a first bump 101 and a first card slot 103. The inner bottom of the main platform 1 is rotatably connected with gears; the auxiliary platform 2 is fixedly installed with a displacement sensor 204 and a control unit 205. The front and rear ends of the two main platforms 1 are fixedly connected to the fixing part 3 on the side away from each other. The fixing part 3 includes a water collection unit 301. The size of the opening of the water collection unit 301 is controlled by the control unit. One end of the main platform 1 is fixedly connected to the cover plate 5. The other end is in a closed state, and a...

Embodiment 3

[0056] On the basis of Embodiment 2, when the water in the elevator machine room is discharged through the water collecting unit 301, since the water collecting unit 301 is set in a conical shape, there is a problem of clogging during the drainage process. When the water collecting unit 301 is blocked, according to this The method described in the example is controlled.

[0057]There is a water outlet hole at the bottom of the side of the main platform 1 close to the water collection unit 301. When the push ball 804 moves upward, the displacement sensor 204 will feed back the displacement change of the push ball 804 to the control unit 205, and the control unit 205 will press the The displacement of the ball 804 controls the size of the opening of the water collection unit 301. When the ball 804 is pressed to move to the top of the through groove 501, the contact plate 801 pushes the locking part 7 to move downward, releasing the restriction of the locking part 7 on the gear. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com