Method for continuously controlling the particle size distribution of powders used in the ceramics industry, and plant for its implementation

A technology of particle size distribution and milling equipment, applied in particle size analysis, particle and sedimentation analysis, measuring devices, etc., can solve problems such as errors, statistical uncertainties, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

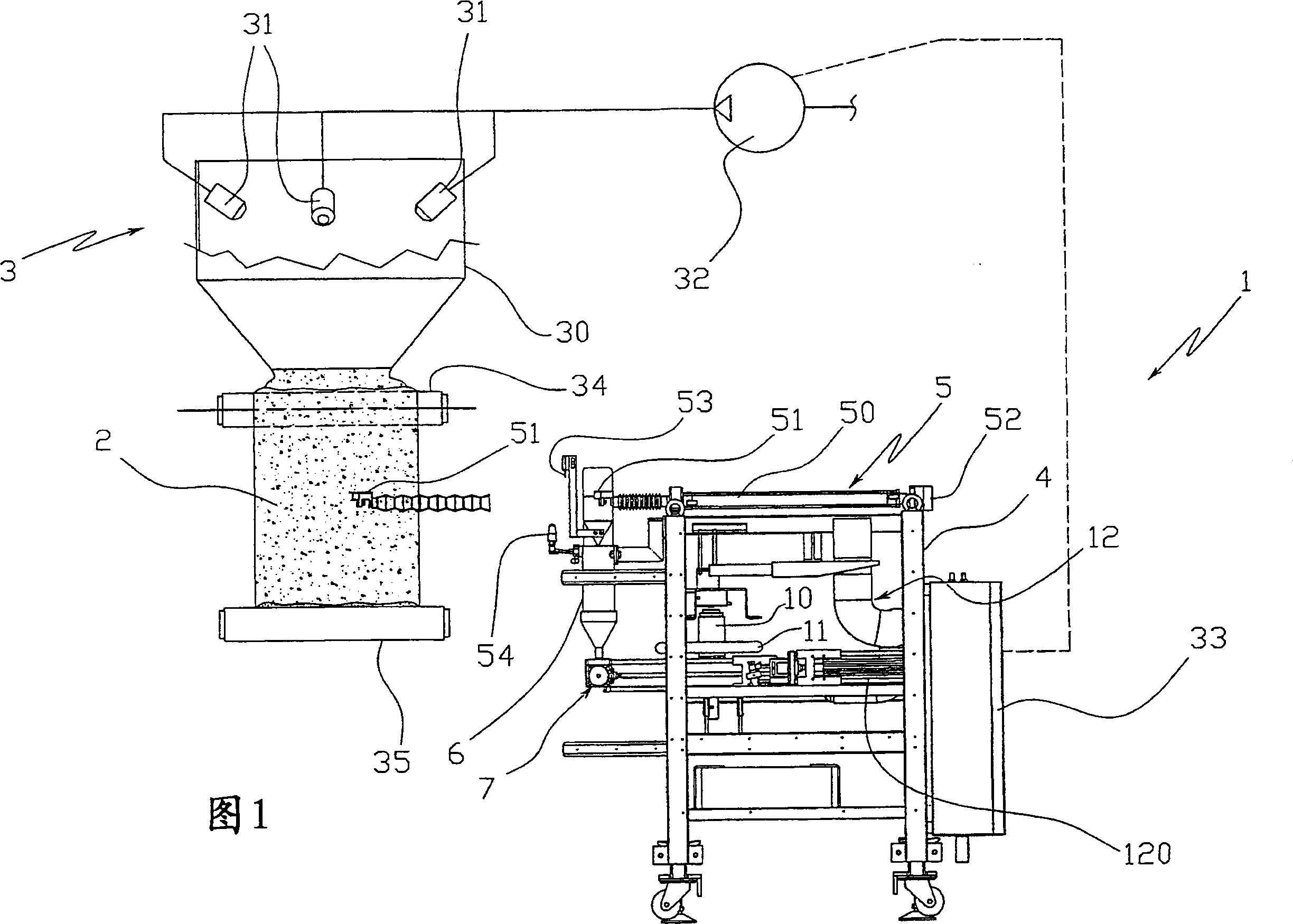

[0035] Said figure shows a device 1 for continuously controlling the particle size distribution of powder 2 produced by a suitable system 3.

[0036] The system 3 basically includes a known atomizer 30, and the slurry to be processed is sprayed into the aforementioned atomizer 30 from a nozzle connected to a feed pump 32.

[0037] Based on the particle size distribution value of the powder 2 measured by the device 1 at the outlet of the atomizer 30, the pressure of the slurry delivered by the feed pump 32 is operated and controlled by the processor 33 and via a suitable adjustment mechanism.

[0038] When the slurry has been processed, the atomizer 30 discharges the powder 2 onto the first conveyor belt 34, which then deposits the powder 2 on the second belt 35 located below, which is arranged as The powder is transferred to a storage area not shown.

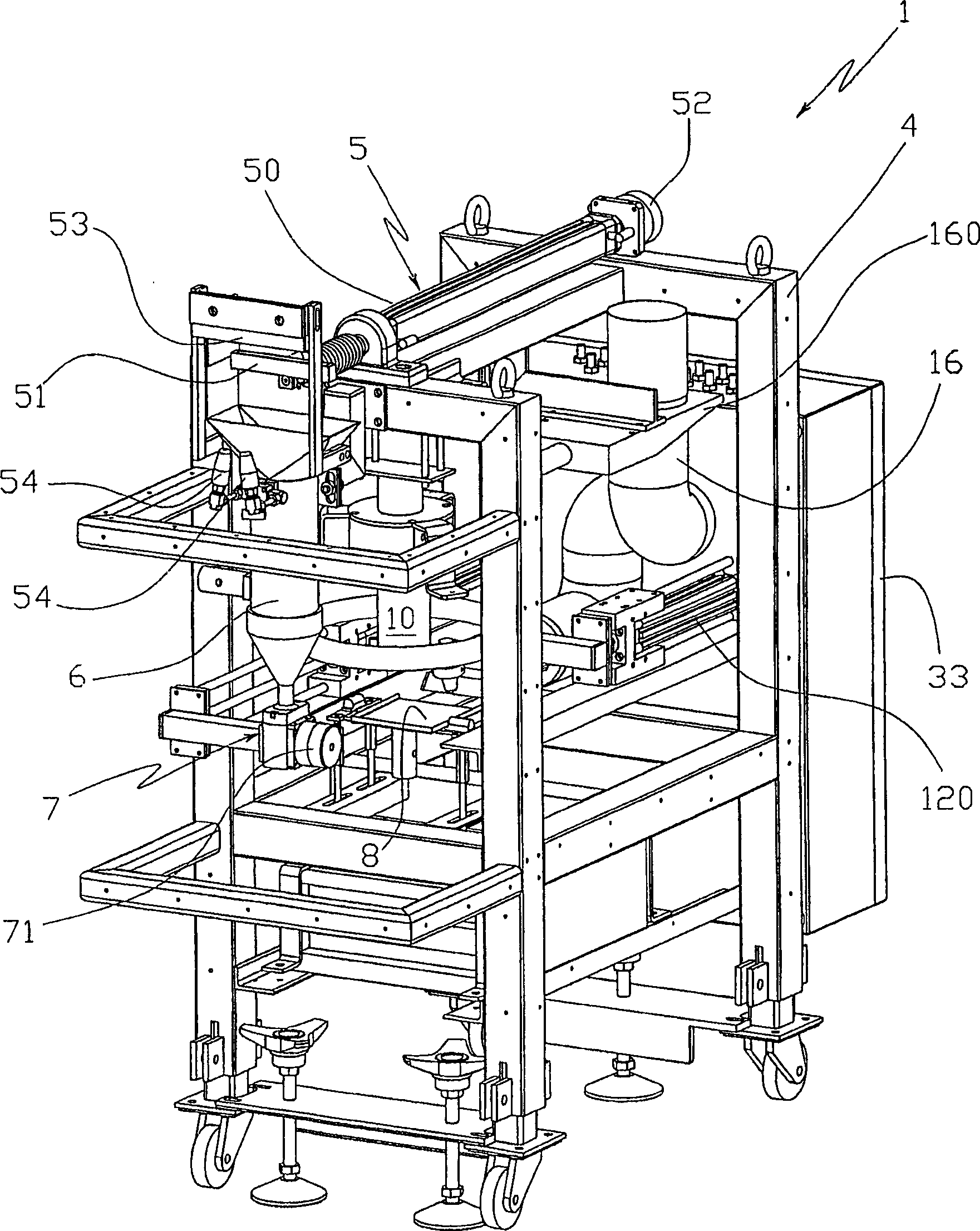

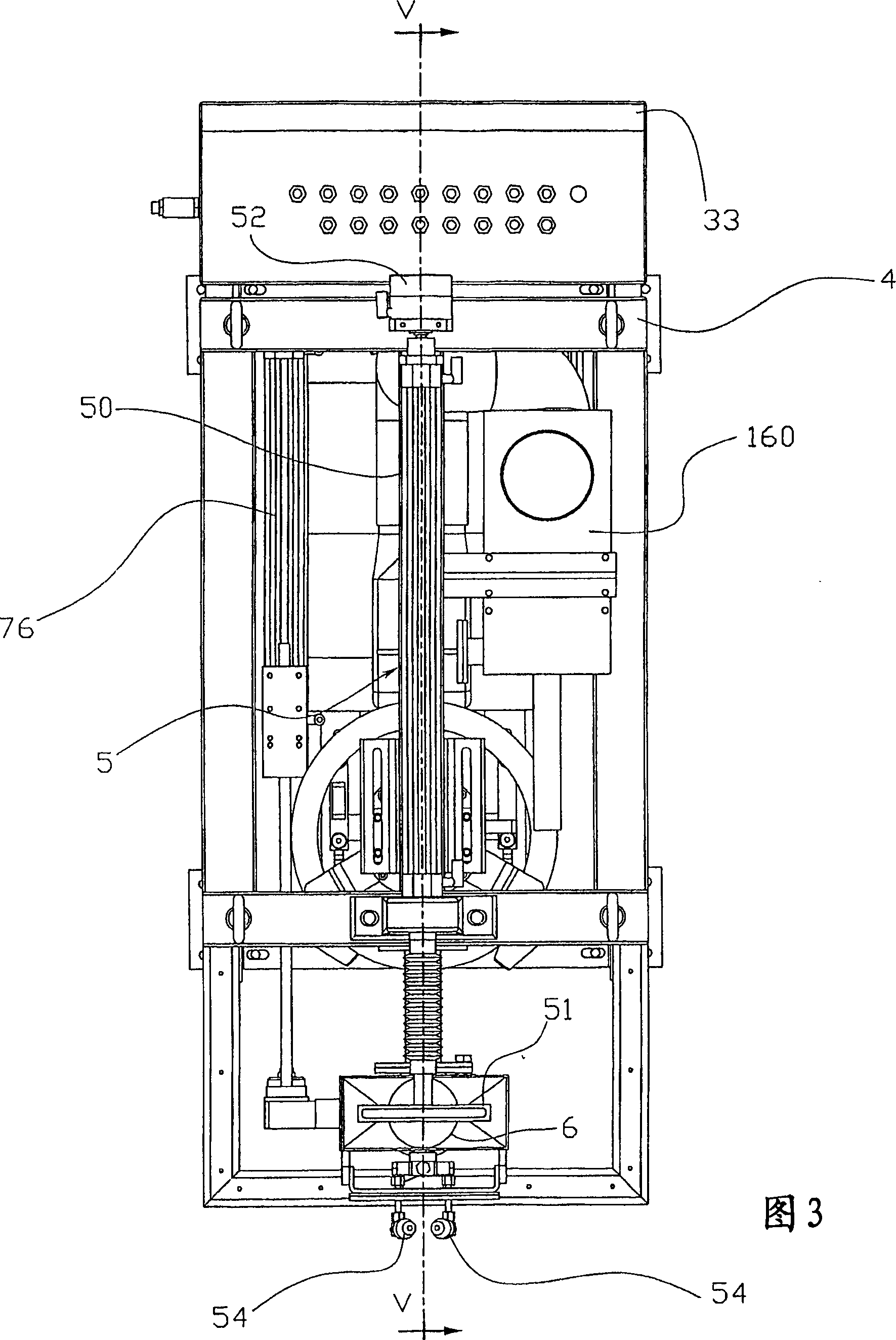

[0039] It can be seen from the figure that the device 1 for controlling powder particle size distribution includes a frame 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com