Robot used for logistics warehousing

A logistics and warehousing technology, applied in the field of logistics and warehousing, can solve problems such as manual unloading, and achieve the effect of great practicability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

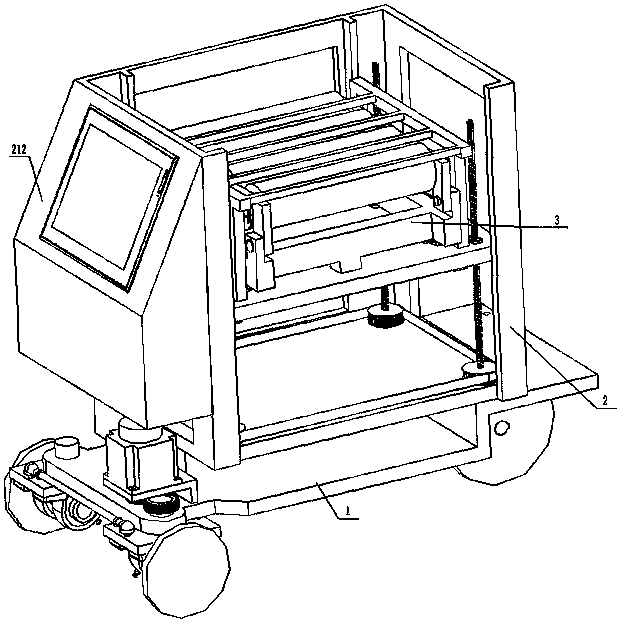

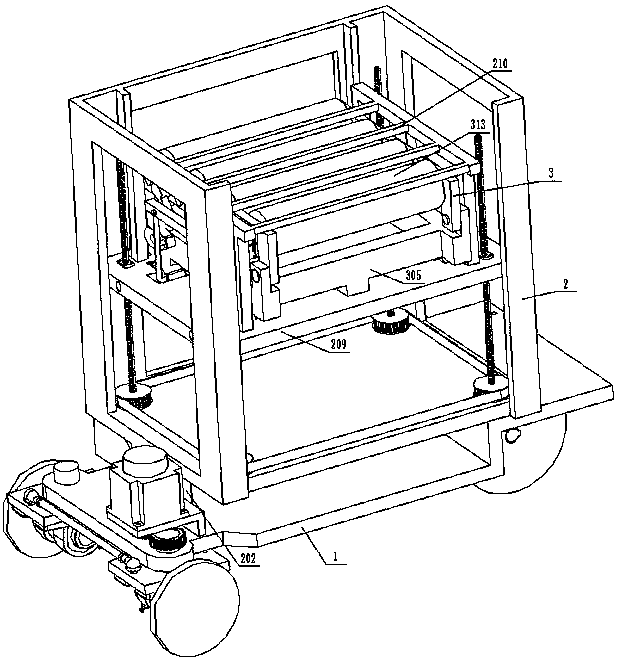

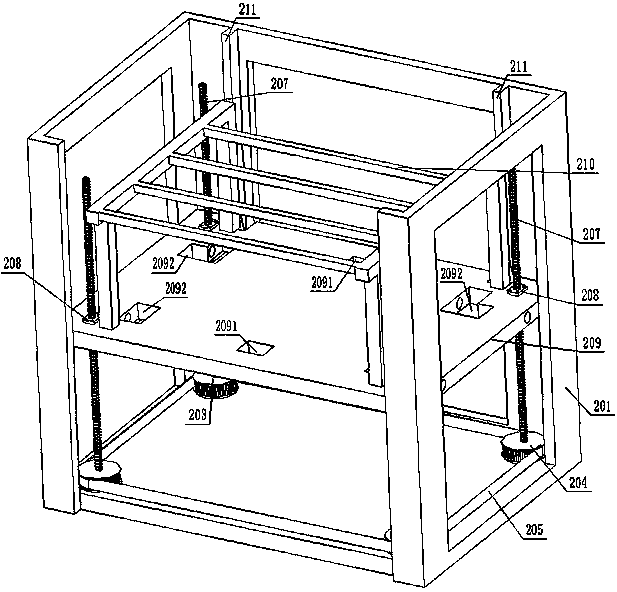

[0019] The present invention is clearly and completely described below in conjunction with the accompanying drawings, as figure 2 As shown, a robot for logistics and warehousing includes an AGV trolley 1, a main lifting assembly 2 and an auxiliary lifting assembly 3, and the first-level lifting platform 305 of the auxiliary lifting assembly 3 is inserted into the first-level lifting platform of the main lifting assembly 2 In the insertion hole 2091, the first-stage camshaft 302 of the auxiliary lifting assembly 3 is fixedly installed on the lifting platform 209 in the main lifting assembly 2, and the first-stage cam 303 and the second-stage cam 304 are placed on the lifting platform The cam of 209 is placed in the hole 2092, the loading roller 313 of the auxiliary lifting assembly 3 is below the loading frame 210 in the main lifting assembly 2, and the main lifting assembly 2 is placed on the AGV trolley 1.

[0020] Among them, such as Figure 2-4 As shown, the main lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com