Method for determining ratio of reconstituted tobacco leaves obtained by paper-making method in cigarettes

A technology of reconstituted tobacco leaves and papermaking method, which is applied in the field of determining the blending ratio of reconstituted tobacco leaves by papermaking method in cigarettes, can solve the problems of inconvenient and fast detection technology, and achieve single variable, good reproducibility, and optimized blending process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for measuring the blending ratio of reconstituted tobacco leaves in cigarettes by papermaking method has the following specific steps:

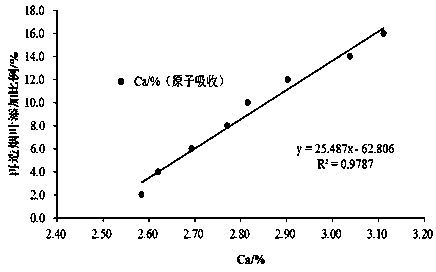

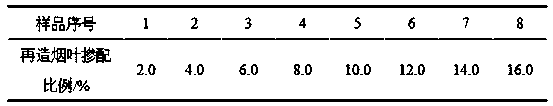

[0033] (1) Preparation of standard working curve

[0034] Step 1. Firstly, at the exit of the equipment after the pre-mixing of the cigarette making thread and before flavoring and shredding, take the shredded leaf of the specific cigarette brand and the reconstituted tobacco leaf of the papermaking method (general sampling through YC / T 5-1992 tobacco batch raw material sampling) The extraction is carried out in principle, and the shredded tobacco of A Yunyan (Dazhongjiu) cigarettes of Hongyun Honghe Group Kunming Cigarette Factory is extracted after pre-blending and before shredding, reconstituted tobacco leaves by papermaking method QTX-18), and dried in an oven (YC / T 31-1996 Tobacco and Tobacco Products Sample Preparation and Moisture Determination Oven Method), and then the dried shredded leaves and paper-making reconsti...

Embodiment 2

[0053] The method for measuring the blending ratio of reconstituted tobacco leaves in cigarettes by papermaking method has the following specific steps:

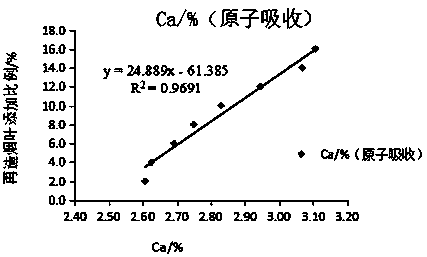

[0054] (1) Preparation of standard working curve

[0055] Step 1. Firstly, at the exit of the equipment after the pre-mixing of cigarette shreds and before flavoring and shredding, take the shredded leaves of specific cigarette brands and reconstituted tobacco leaves by papermaking method (general sampling of tobacco raw materials in batches according to YC / T 5-1992) The extraction is carried out in principle, extracting the shredded tobacco of B Yunyan (soft treasure) cigarettes made by Hongyun Honghe Group Kunming Cigarette Factory, which is pre-mixed and before shredded, reconstituted tobacco leaves KM-13 by papermaking method), and dried by oven method (YC / T 31 -1996 Tobacco and Tobacco Products Sample Preparation and Moisture Determination Oven Method), and then the dried shredded leaves and paper-making reconstituted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com