Automatic plastering robot for building

A construction automation and robot technology, applied in construction, building construction, etc., can solve the problems of high labor intensity, high requirements of practitioners, harsh working environment, etc., and achieve the effect of convenient movement and flexible walking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

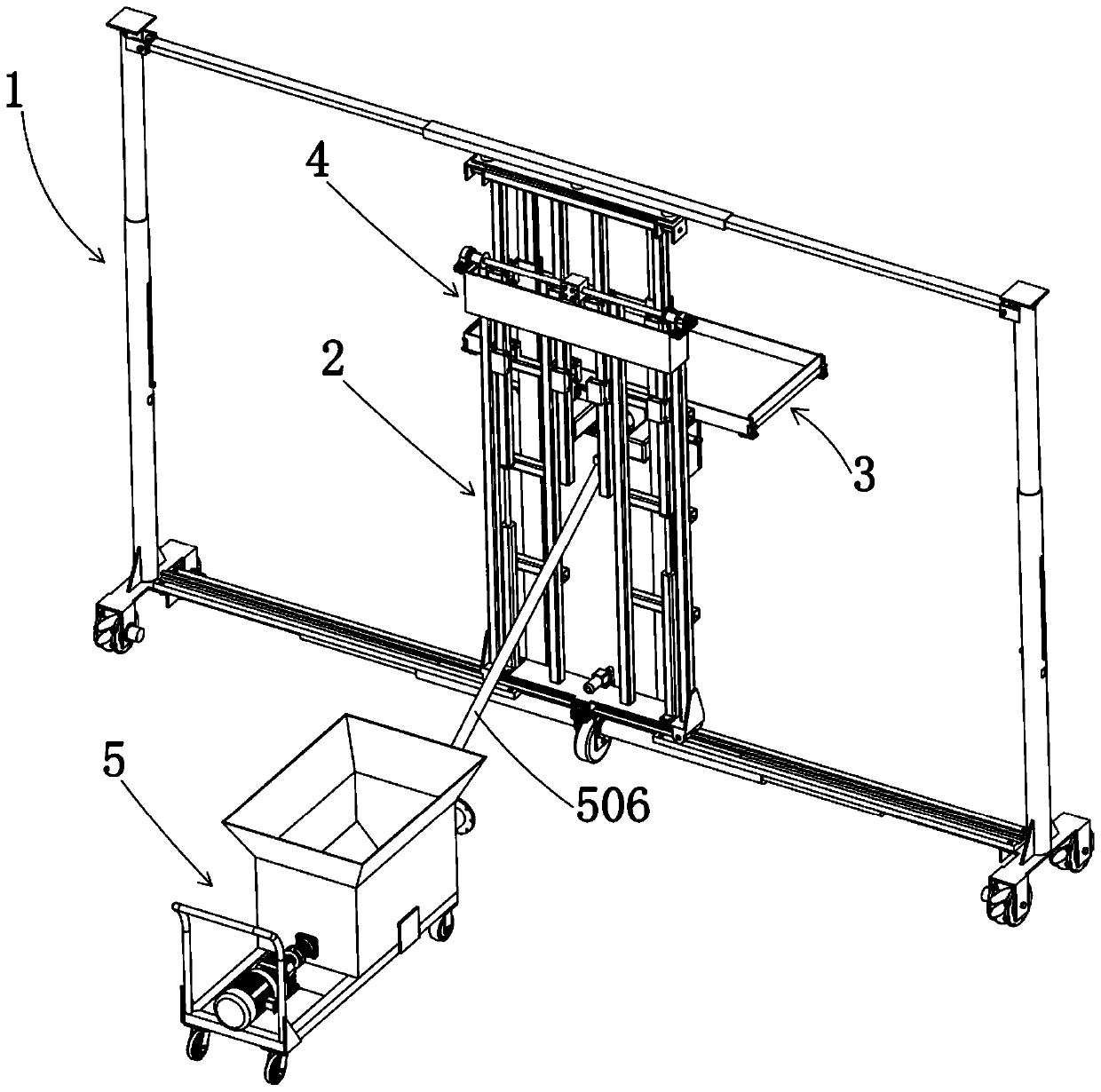

[0040] see Figure 1-16 As shown, a building automatic plastering robot includes a first frame mechanism 1, a second frame mechanism 2 arranged in the first frame mechanism 1, a plastering mechanism 3 arranged on the second frame mechanism 2, and a plastering mechanism arranged on the second frame mechanism 2. The driving mechanism 4 on the frame mechanism 2 is used to drive the plastering mechanism 3 to move up and down, and the feeding mechanism 5 is used to transport the ashes to the plastering mechanism 3 .

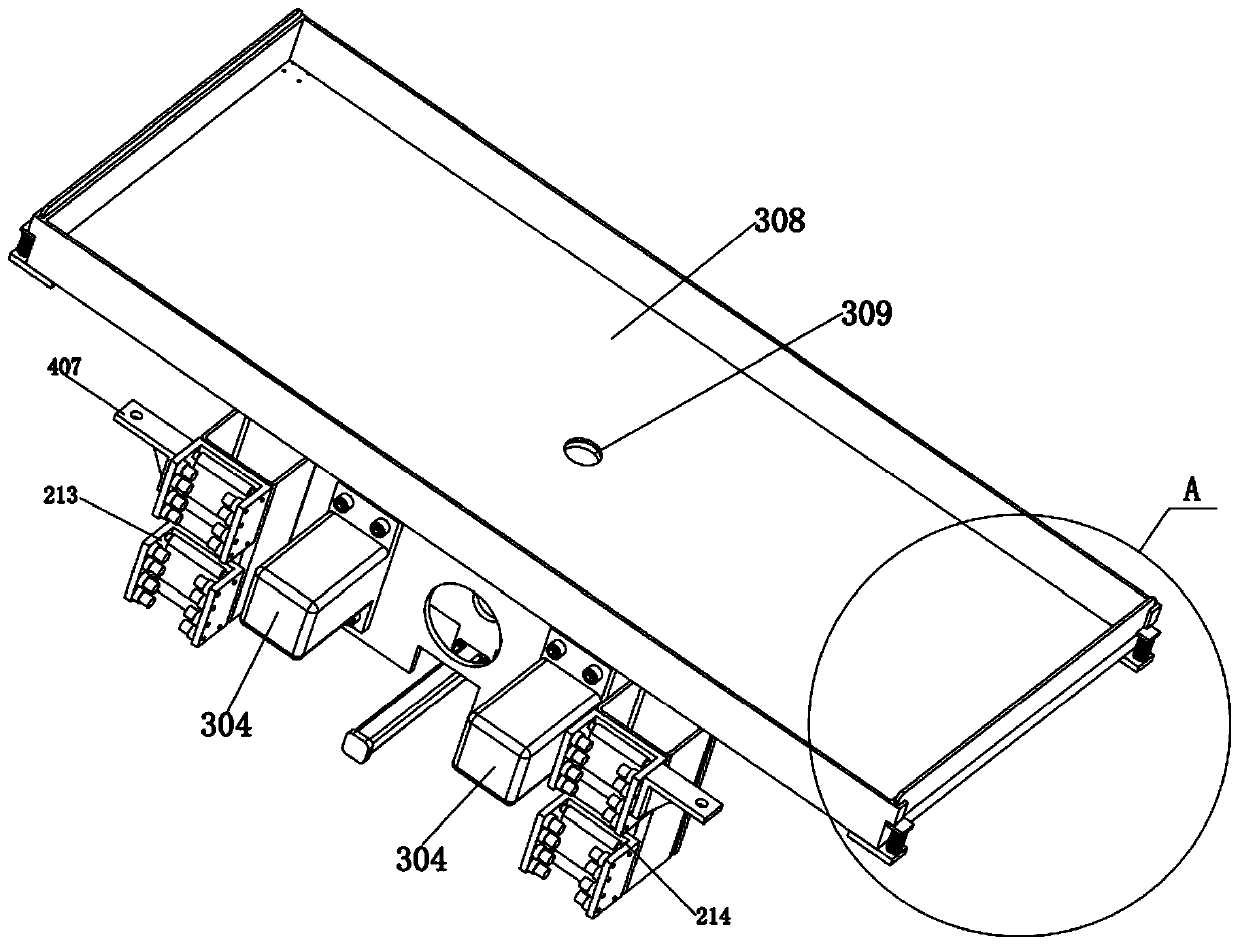

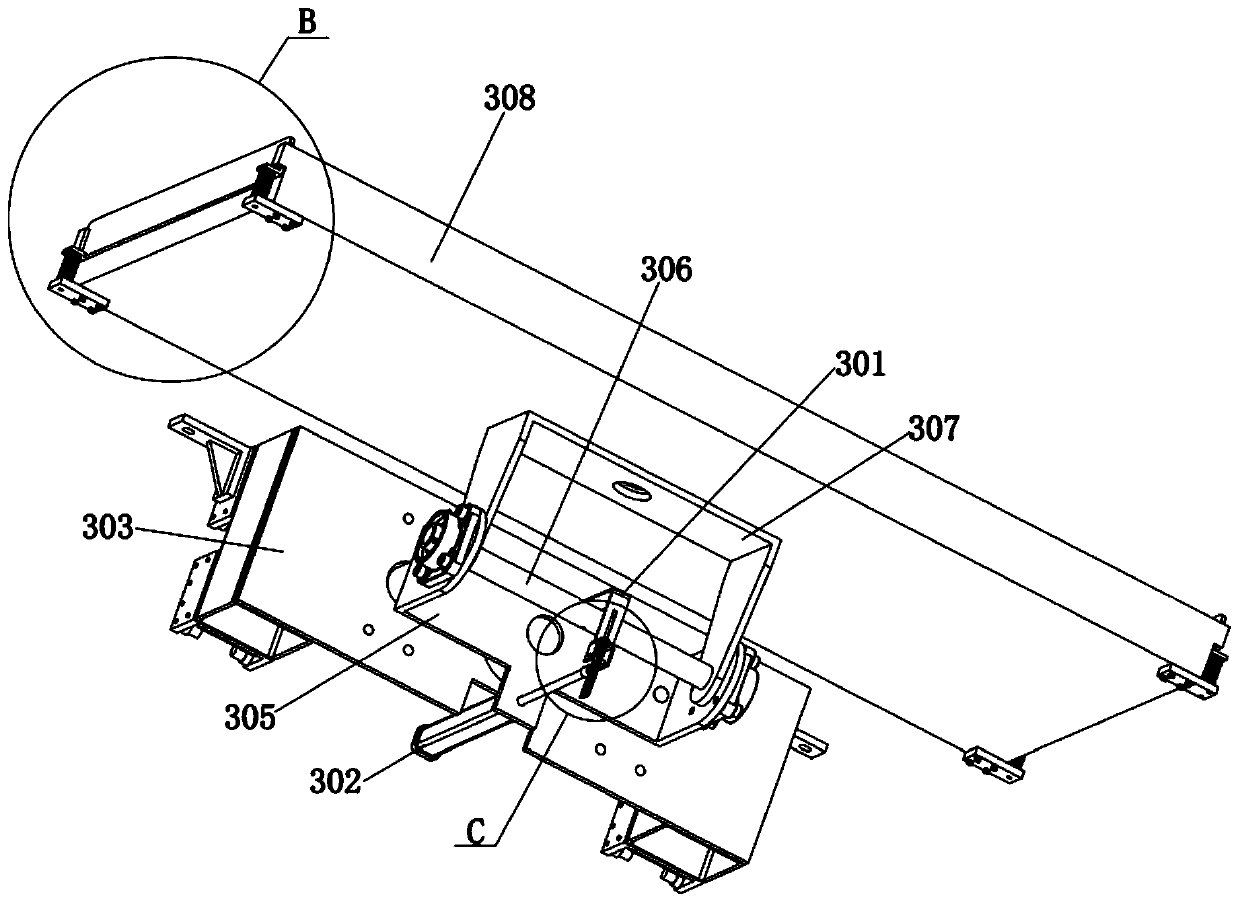

[0041] The plastering mechanism 3 includes an L-shaped connecting rod 301, an overturning cylinder 302, and an ash bucket base 303 slidingly connected to the second frame mechanism 2, and two adjustment cylinders are horizontally arranged side by side on the ash bucket base 303 304, a U-shaped turning seat 305 is arranged between the telescopic ends of the two adjusting oil cylinders 304, and a turning shaft 306 is rotatably connected to the turning seat 305, and a U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com