Preparation method of fixed perforation rock sample

A technology for rock sample and surface determination, applied in the field of physical simulation experiments, can solve the problems of inability to repeat experiments, high cost, and inoperability, saving preparation time and cost, saving experimental costs, and realizing precise control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

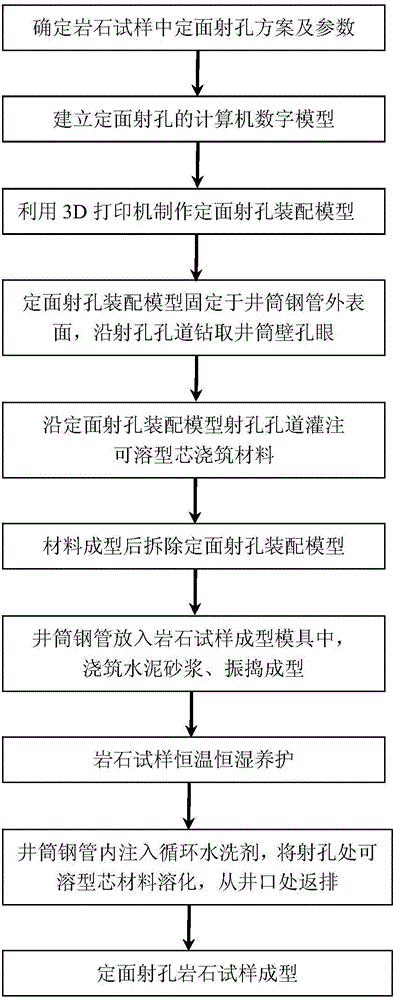

[0040] The invention provides a method for preparing a rock sample for fixed-surface perforation, such as figure 1 As shown, it includes the following steps:

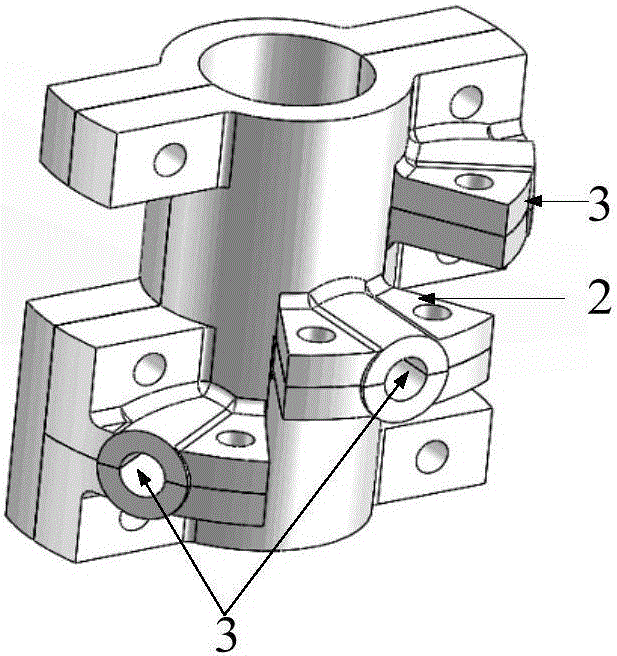

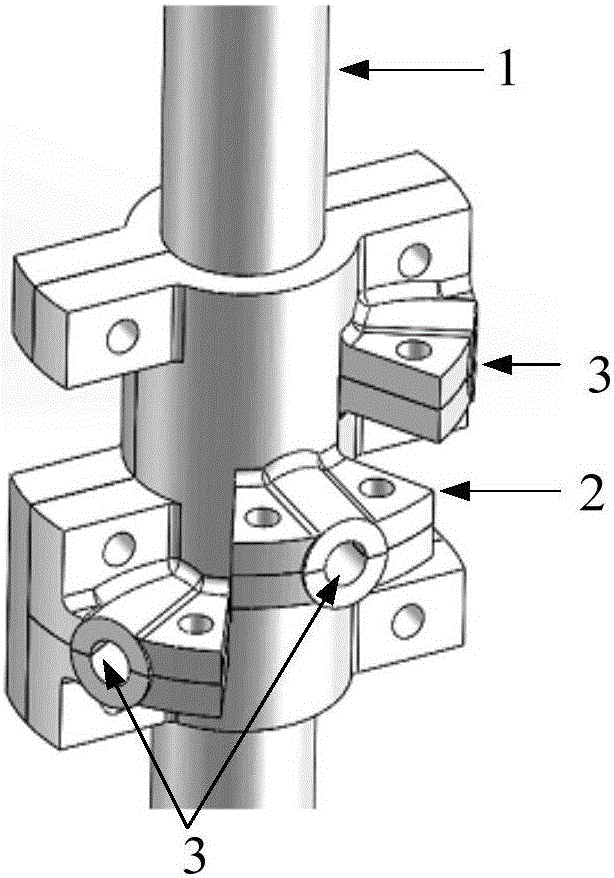

[0041] A. According to the parameters of the fixed surface perforation in the rock sample, the multi-cluster fixed surface perforation assembly model is directly obtained through the 3D printer;

[0042] B. Fix the corresponding fixed-plane perforation assembly model on the outer surface of the wellbore steel pipe, drill holes on the wellbore steel pipe wall along the direction of the perforation tunnel, and then pour soluble cores into the perforation tunnel of the fixed-plane perforation assembly model Casting materials, soluble core pouring materials are filled in the perforation channels and holes;

[0043] C. After the soluble core pouring material is dried and hardened in the air, the fixed surface perforation assembly model is removed, and a soluble simulation rod for simulating the perforation channel is formed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com