Ridger capable of forming ridge through overturn and reverse push

A ridge-building machine and ridge-building technology, applied in the fields of farming machines, agricultural machinery and tools, applications, etc., can solve the problems of affecting the working speed, inconvenient building ridges, inconvenient horizontal adjustment, etc., so as to improve the working speed and facilitate the horizontal adjustment , the effect of the same direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

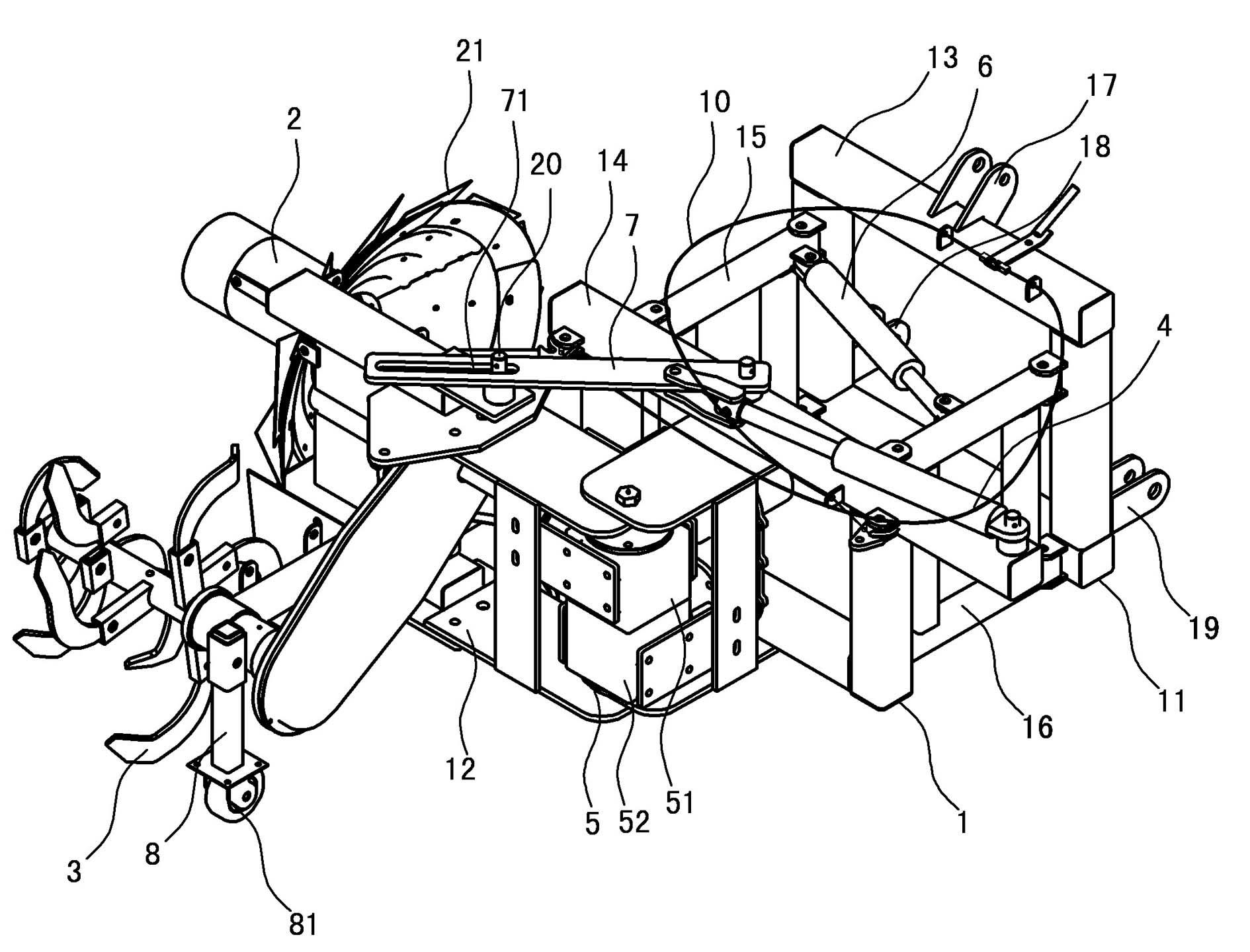

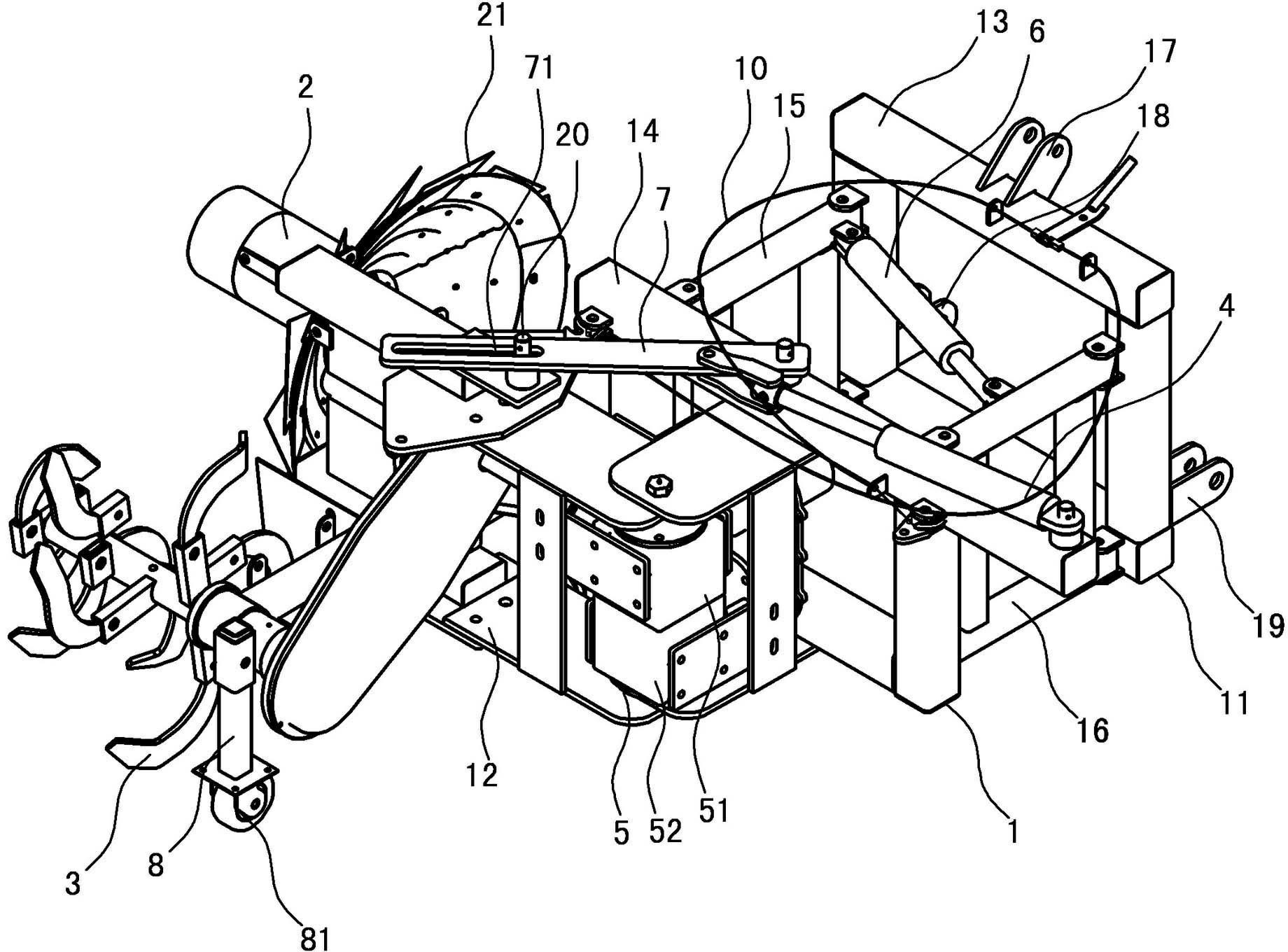

[0008] It also includes a gearbox 5 installed between the traction suspension frame 11 and the ridge frame 12 for rotary tillage. The upper box body 51 and the lower box body 52 are composed of two parts. The upper box body 51 is installed on the traction suspension frame 11, and the upper box body 51 is connected with the input shaft 53 connected with the tractor. The lower box body 52 is installed on the rotary tiller. The first output shaft and the second output shaft connected on the upper and lower boxes 52 of the ridge frame 12 are respectively connected with the ridge wheel 2 and the rotary tiller wheel 3 by chains.

[0009] The traction suspension frame 11 and the rotary tillage building ridge frame 12 can be locked to prevent the traction wire rope 10 from turning over automatically after the traction suspension frame 11 and the rotary tillage building ridge frame 12 are provided with the rotary tillage building ridge frame 12 and turned over and positioned.

[0010] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com