Riprap elephant trunk retraction system for immersed tube foundation construction

A technology for foundation construction and stone chute, which is applied in the field of riprap devices, can solve problems such as potential safety hazards, and achieve the effects of small occupied space, reasonable design, and easy and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

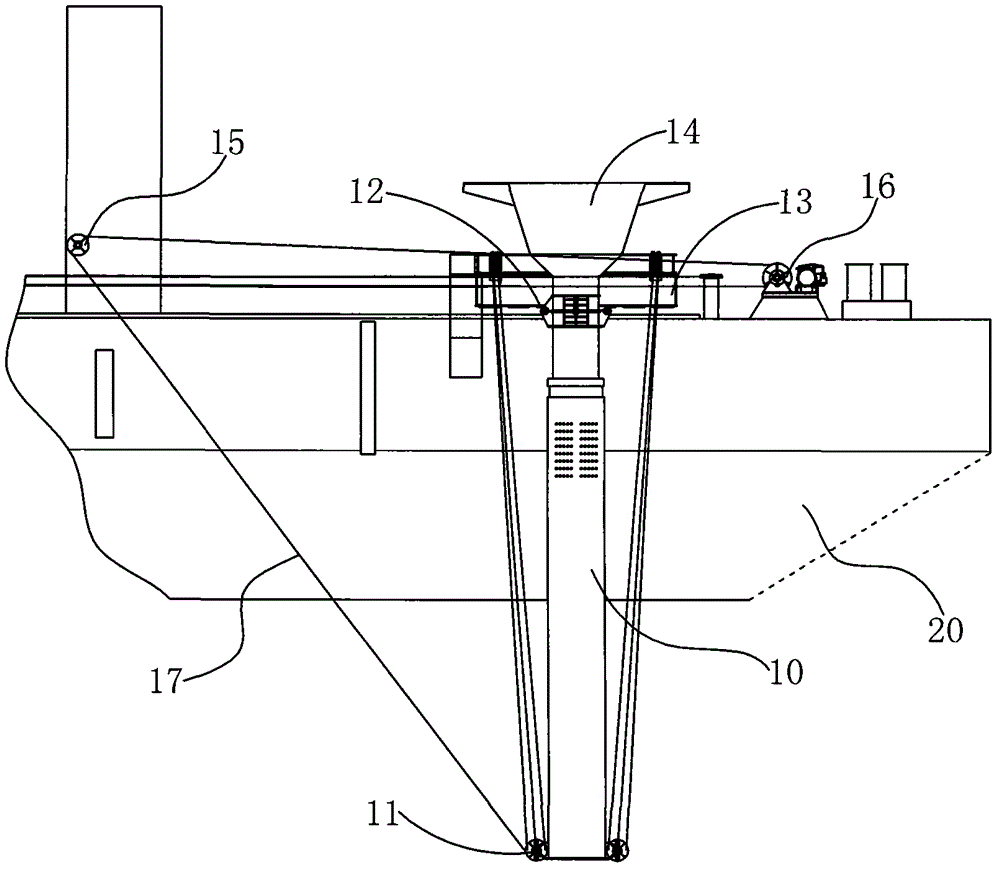

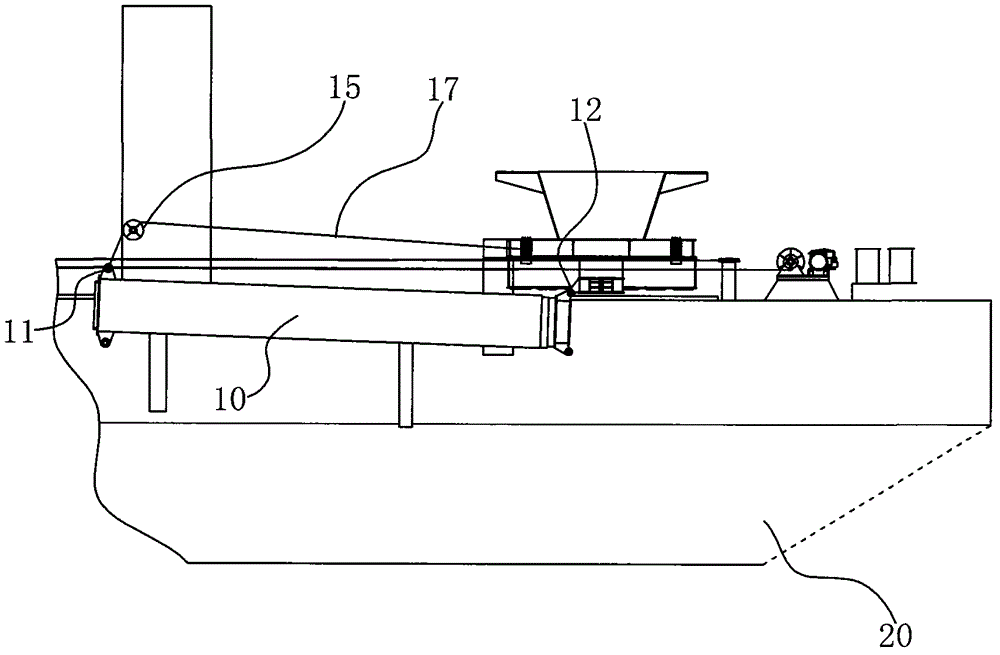

[0016] Such as figure 1 and figure 2 As shown, the riprap chute retracting system for the immersed tube foundation construction can be set on the immersed tube foundation construction barge 20, which mainly consists of a riprap chute 10 and a retractable traction cable 17. The riprap chute 10 is a multi-section cylindrical tube set in a movable suit, the upper end of the innermost cylindrical tube is connected to the lower port of the riprap funnel 14, and the upper part of the innermost cylindrical tube is pivotally connected to the chute trolley. . The upper part of the innermost cylindrical tube of the riprap chute is pivotally connected to the chute trolley through the ear plate 12; Set retractable traction rope 17 traction settings. The riprap chute is arranged on a chute trolley 13, which is assembled with a track, and a pulley 15 is arranged at intervals on one side of the chute trolley, and the other end of the retractable traction cable 15 passes through the pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com