Precision spherical hinge clearance-measuring instrument and measurement method

A technology of ball hinges and measuring instruments, which is applied in the direction of measuring devices, instruments, and electric devices, etc., can solve the problems of complex influence on motion accuracy and difficult error models, and achieve simple structure, easy pressurized load, improved rigidity and rotation The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

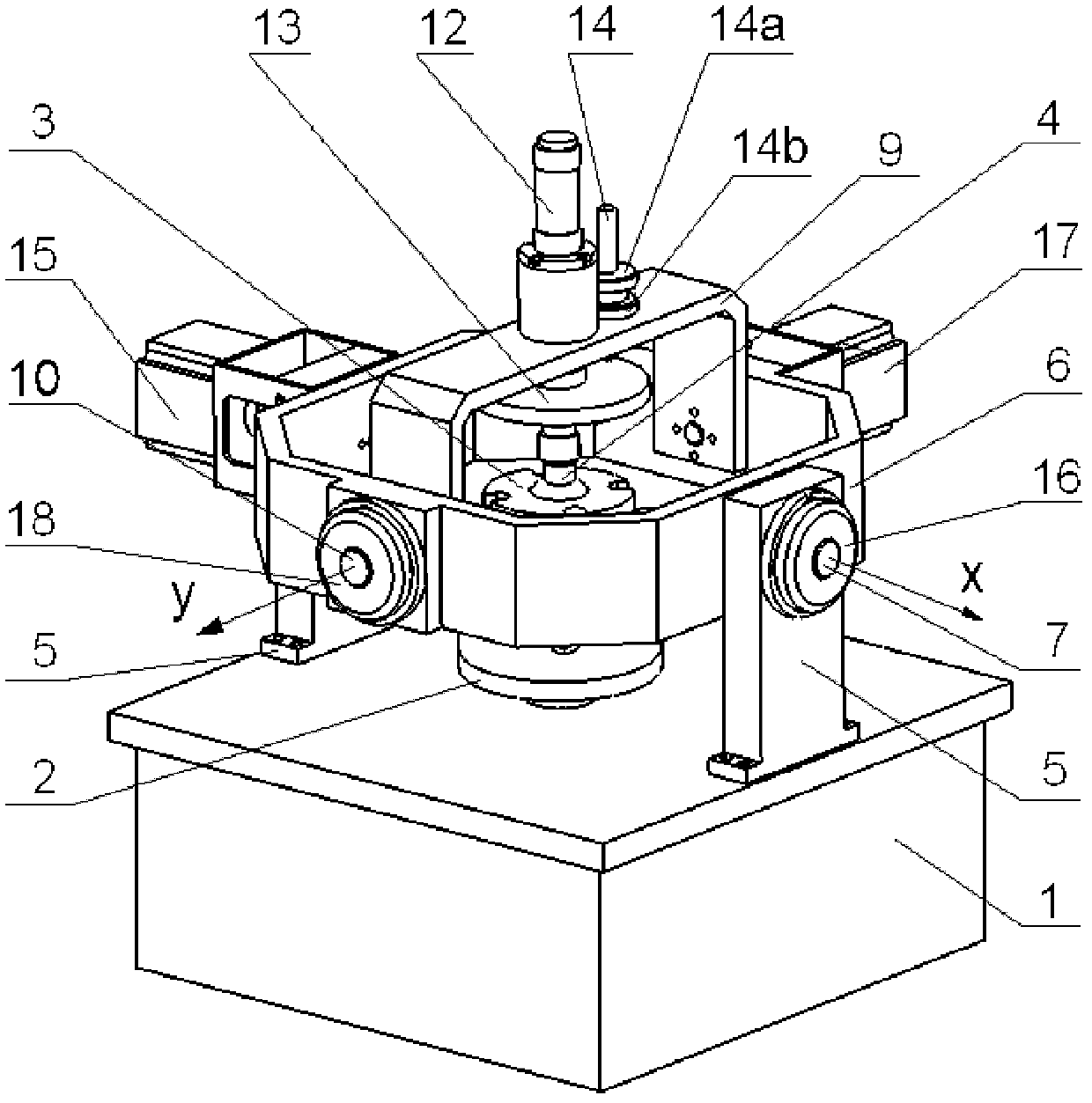

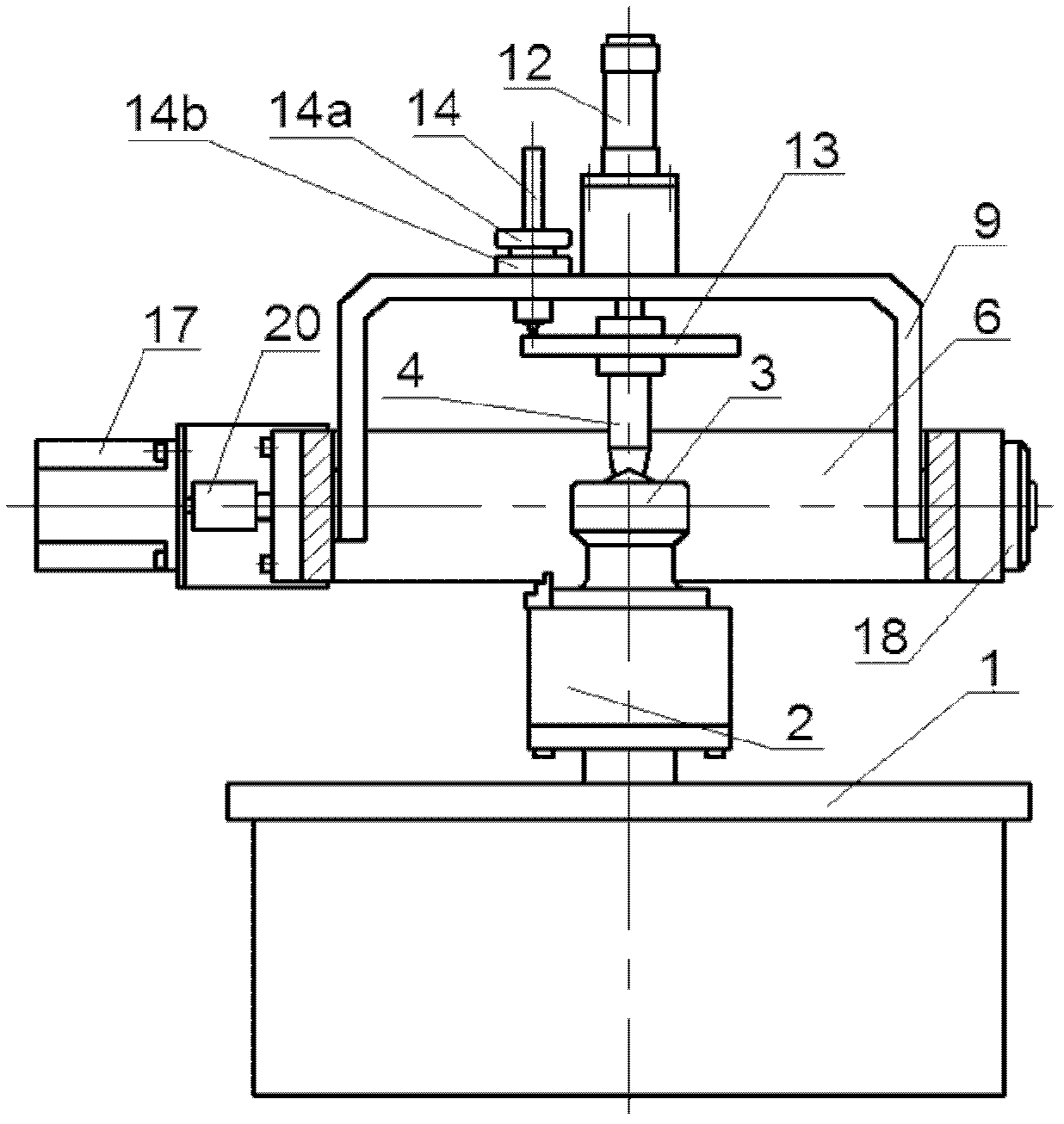

[0049] The structure of the precision ball hinge gap measuring instrument in this embodiment is set as follows:

[0050] like figure 1 and image 3 As shown, the chuck fixture 2 is fixedly arranged on the horizontal base platform 1, the ball hinge seat 3 of the ball hinge to be tested is fixedly arranged in the chuck fixture 2, and the ball hinge rod 4 of the ball hinge to be tested is vertical; On the base platform 1 and on both sides of the chuck fixture 2, vertical outer frame supports 5 are arranged symmetrically.

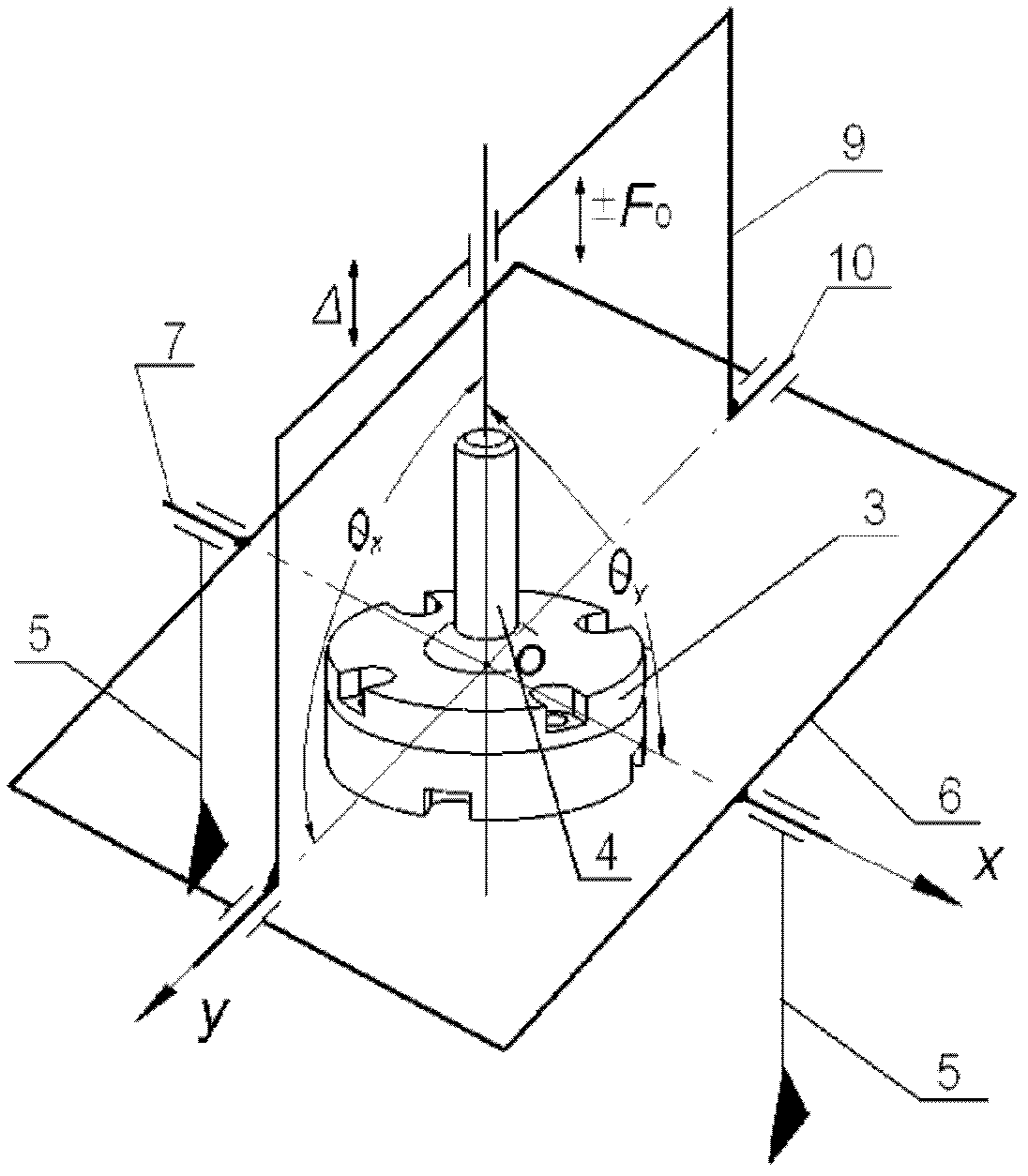

[0051] On the rectangular outer frame 6, a pair of opposite side frames are respectively provided with outer frame half shafts 7 along the X-axis direction, and the other pair of opposite side frames are respectively set as inner frame bearing seats, and the inner frame The axis of the bearing seat is arranged along the Y-axis direction; the rectangular outer frame 6 is supported on the vertical outer frame support 5 by the outer frame half shaft 7 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com