Station crossing device and method for shield tunneling machine

A shield machine and station-passing technology, which is applied in the fields of earth drilling, transportation and packaging, mining equipment, etc., can solve the problems of slow moving speed, slow construction period, and difficult work, and achieve consistency, easy operation, and work Effect of Difficulty Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

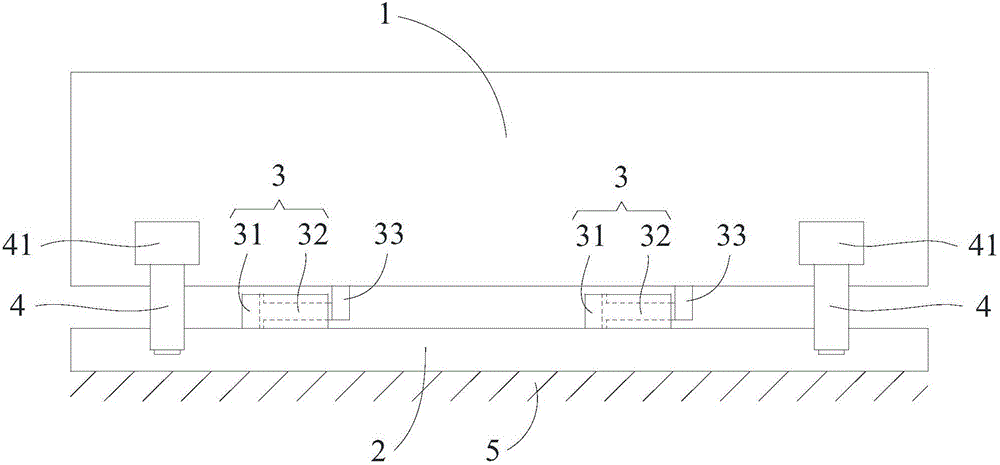

[0047] Such as Figure 1-5 As shown, a shield machine passing device according to the present invention includes:

[0048] The bracket 2 is used to receive the shield machine 1 at the exit of the tunnel at one end of the site, carry the shield machine 1 during the process of transferring the shield machine 1, and use the excavation point of the shield machine 1 at the other end of the site as the shield The counter force frame for the excavation of mechanism 1;

[0049] The piston mechanism includes two piston assemblies 3, each of which is connected to the shield machine 1 and the bracket 2 for horizontal movement between the shield machine 1 and the bracket 2;

[0050] The jacking mechanism includes four jacking assemblies 4, and each jacking assembly 4 is connected to the shield machine 1 for jacking the shield machine 1 and the bracket 2 higher than the foundation 5 by about 200mm.

[0051] As a preferred solution of this embodiment, the shield machine 1 is provided wit...

Embodiment 2

[0057] Such as Figure 1-6 As shown, a shield machine passing method according to the present invention, using the shield machine passing device as described in Embodiment 1, is characterized in that it includes the following steps:

[0058] A. If figure 2 As shown, the shield machine 1 moves: the piston mechanism moves to drive the shield machine 1 to move relative to the bracket 2;

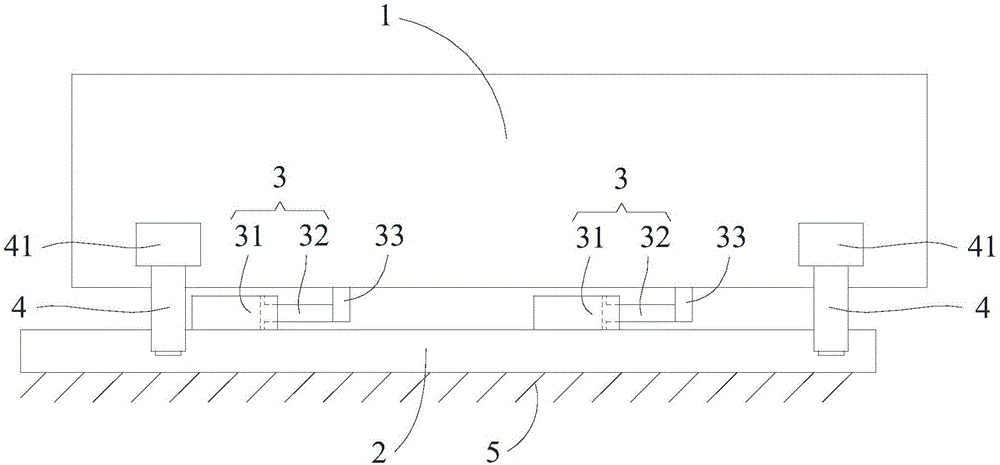

[0059] B. If image 3 As shown, the shield machine 1 is jacked up: the jacking mechanism jacks up the shield machine 1, and drives the bracket 2 away from the foundation 5;

[0060] C. If Figure 4 As shown, the bracket 2 moves: the piston mechanism resets, driving the bracket 2 to move relative to the shield machine 1;

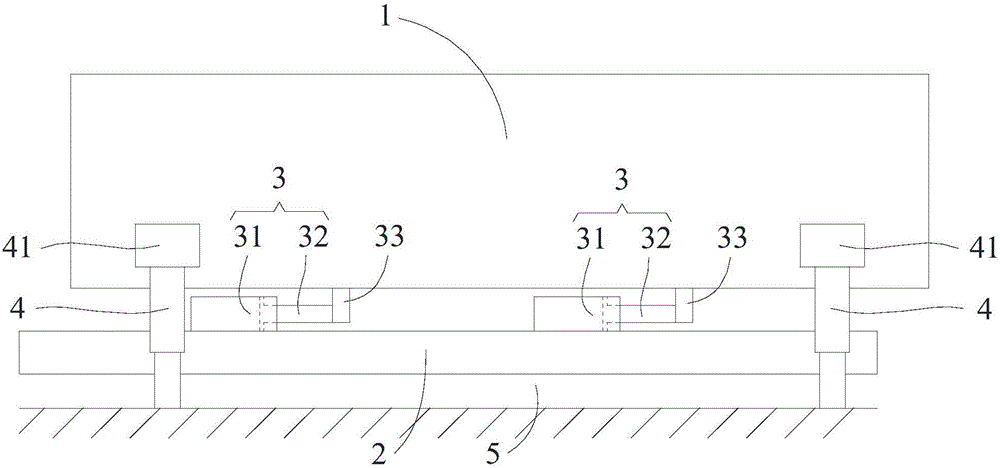

[0061] D. If Figure 5 As shown, the shield machine 1 lands: the jacking mechanism resets;

[0062] E. Cycle operation: repeat the steps A-D until the shield machine 1 passes through the station.

[0063] Using a shield machine passing method described in the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com