Method and device for refining brine by air floatation method

A technology for refining brine and air flotation, which is used in chemical instruments and methods, flotation water/sewage treatment, water/sewage treatment, etc. It can solve the problem that the effect of reducing the turbidity of brine is not obvious and the concentration of suspended solids in the influent cannot be too high. , low removal rate of grease and colloids, etc., to reduce the dissolution equipment, prevent the blockage of salt crystals, and reduce the cost of salt products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, the amount of seawater concentrated brine treated by the air flotation device is 250m 3 / h, the circulating water volume is 40% of the treated water volume, and the dissolved air pressure is 0.30Mpa.

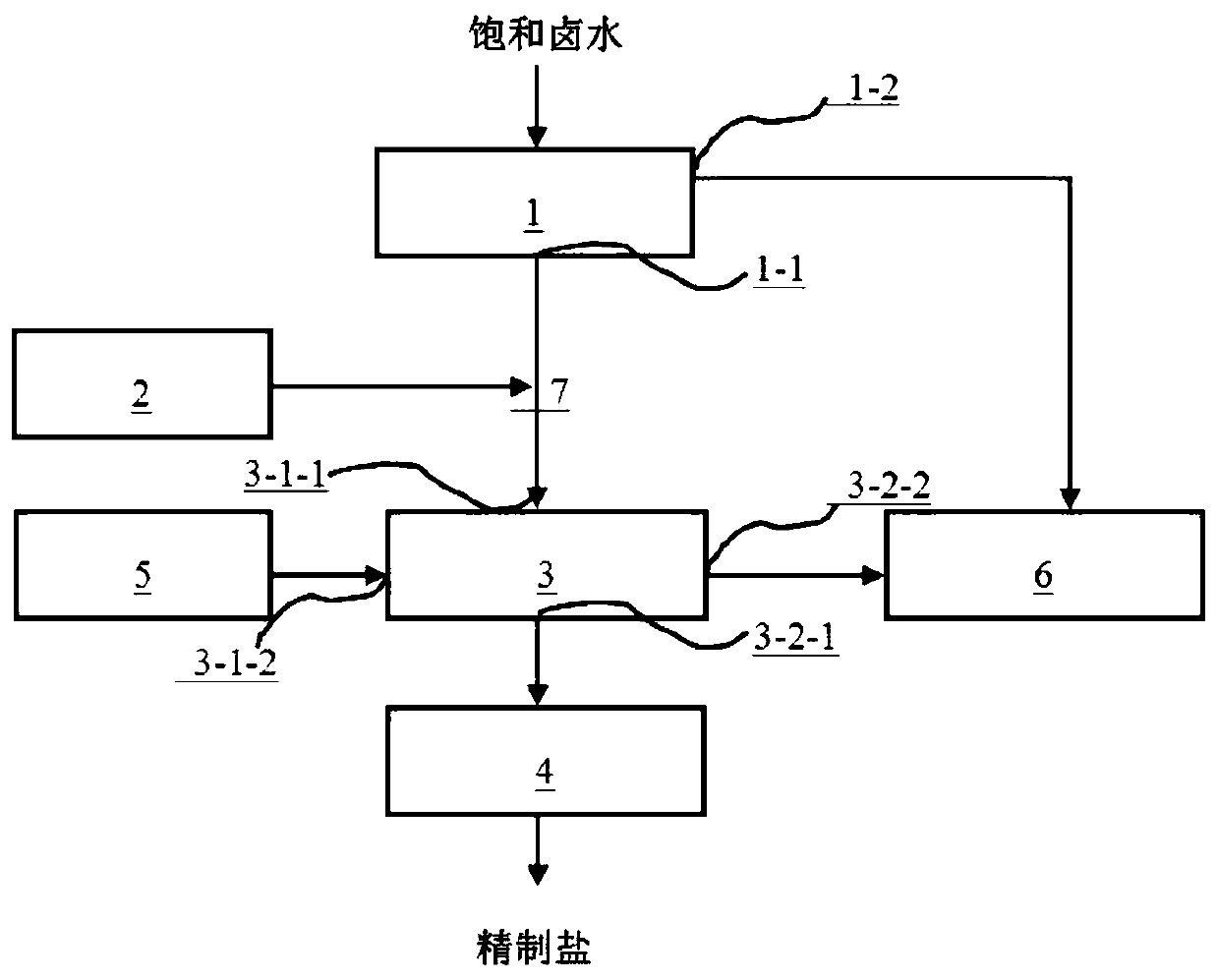

[0054] After removing some impurities from the raw brine, the brine water body is introduced into the settling unit 1 (Dall settler) for sedimentation, and solid-liquid separation is carried out to obtain a preliminary clarified liquid, and the obtained impurities pass through the second discharge port 1-2 of the settling unit 1 Enter the sludge storage tank 6; introduce the preliminary clarified liquid into the first connection port 3-1-1 of the air flotation unit 3 through the first discharge port 1-1 of the settling unit 1, and pass through the remote automatic control system 5 Control the air flotation unit 3, control the brine water temperature at 30°C, and add the flocculant of the drug-dissolving unit 2 to the water pipeline connecting the settl...

Embodiment 2

[0061] The water volume of the air flotation device to treat the mine salt brine is 350m 3 / h, the circulating water volume is 45% of the treated water volume, and the dissolved air pressure is 0.30Mpa.

[0062] After the raw brine is reacted by adding lime, the brine water body is introduced into the settling unit 1 (Dall settler) for settlement, and solid-liquid separation is carried out to obtain a preliminary clarified liquid, and the obtained impurities pass through the second discharge port 1-2 of the settling unit 1 Enter the sludge storage tank 6; introduce the preliminary clarified liquid into the first connection port 3-1-1 of the air flotation unit 3 through the first discharge port 1-1 of the settling unit 1, and pass through the remote automatic control system 5 Control the air flotation unit 3, the water temperature is controlled at 25 ° C, and the flocculant of the drug dissolving unit 2 is added to the water pipeline connecting the settlement unit 1 and the air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com