Integrated production method of organic sewage/waste residue treatment, microalgae culturing and oil refining

A technology for organic sewage and production methods, which is applied in flotation water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., and can solve problems such as eutrophication of water bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and the embodiments given in the drawings. The production technology of the present invention is easy to implement for people in the field.

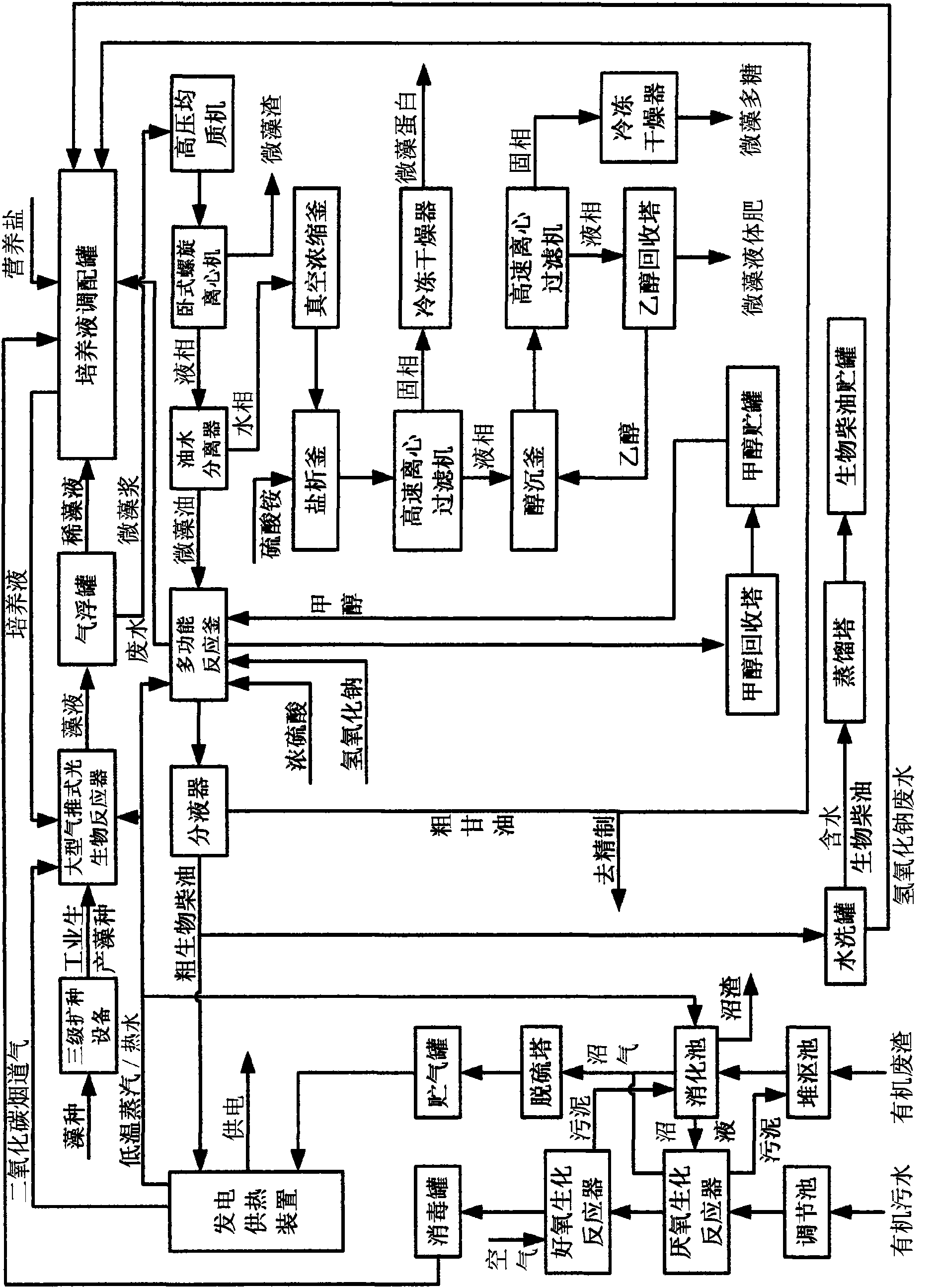

[0024] A sewage treatment plant, a large-scale biogas digester, a microalgae breeding and processing plant, and a biodiesel refinery are built near a large pig farm that produces 100,000 pigs per year. Organic sewage and waste residues (mainly including pig farm manure, urine, Sewage, nearby straw, etc.) coupled with algae cultivation and oil refining production methods to produce biodiesel, microalgal protein, microalgal polysaccharides, microalgal fertilizer, etc., see figure 1 .

[0025] The manure water and washing sewage collected from the pig breeding site are removed by the grille to remove mechanical impurities such as large floating matter and then enter the adjustment tank to adjust the sewage water volume, water quality, and pH value, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com