Phenol and cyanogen waste water physical chemical method control process and equipment

A waste water and equipment technology, applied in the direction of water pollutants, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems that waste water cannot reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

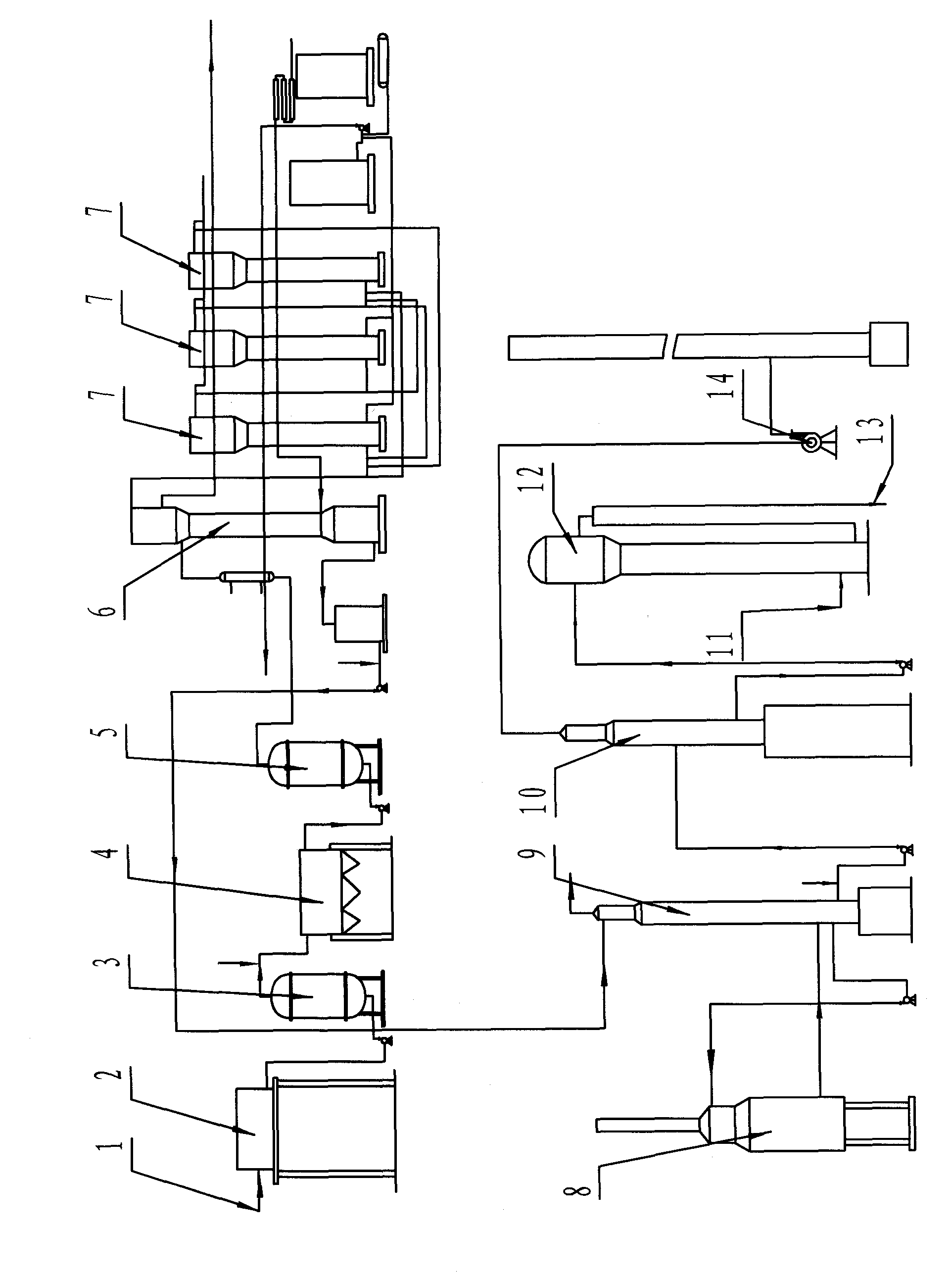

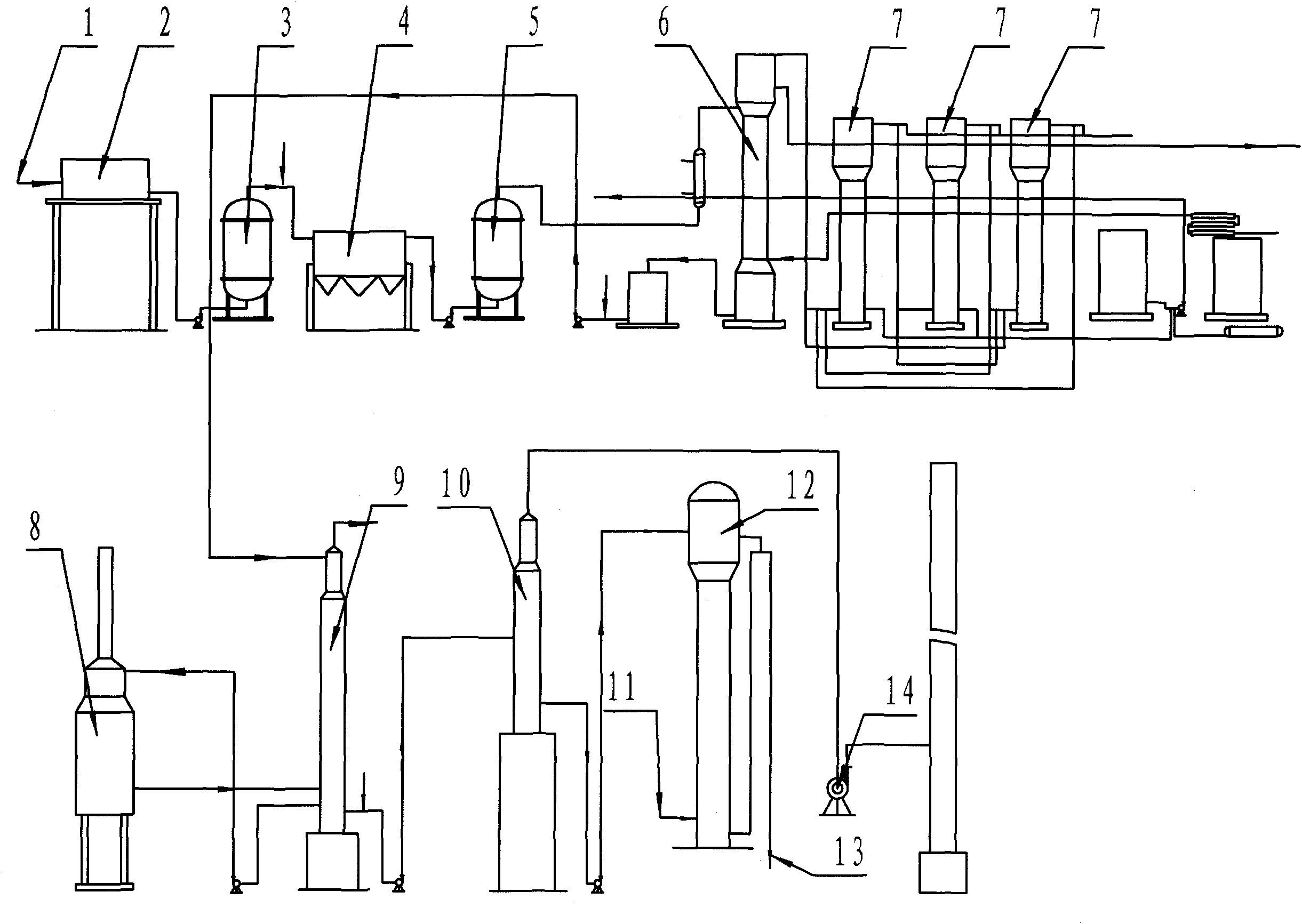

[0049] Embodiment 1, a kind of phenol cyanide-containing waste water physicochemical treatment process is characterized in that: its main process is

[0050] Wastewater containing phenol and cyanide→air flotation method for oil removal→iron condensation method for cyanide and sulfur removal→extraction and phenol removal→tubular furnace method for ammonia distillation→decompression method for NH removal 3 -N, phenol and organic matter, sulfur cyanide and other pollutants → ozone catalytic oxidation → standard waste water is used for coke quenching

[0051] The ferrocoagulation method for H removal 2 S, HCN is carried out in two steps. The first step is the H in the wastewater 2 S and HCN first react with active iron in the reactor to generate FeS and Fe 2 [Fe(CN) 6 ] or Fe 4 [Fe(CN) 6 ]3 precipitates, thus most of the H 2 S, HCN removal, the second step: to speed up and the remaining H 2 S, HCN reaction speed, add coagulant and flocculant to achieve the purpose of separ...

Embodiment 2

[0055] Embodiment 2, as shown in the figure: the equipment used in the treatment process of phenol cyanide wastewater physicochemical method, its structure is: mainly by successively connected air flotation and degreasing equipment, ferrocondensation and cyanide and sulfur removal equipment, extraction and phenol removal equipment, distillation Composition of deamination equipment. Ferrocoagulation cyanide and sulfur removal equipment is composed of ferrocoagulation reactor, reaction clarifier and filter connected in sequence. The extractive phenol removal equipment includes an extraction tower and multiple alkali washing towers connected in series.

[0056] The distillation denitrification equipment includes an ammonia distillation tower connected to a tubular heating furnace and a decompression phenol cyanide stripping tower connected to its outlet, the stripping tower is connected with a catalytic oxidation tower, and the catalytic oxidation tower is connected with a treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com