Treatment method of cutting fluid wastewater of automobile engine

A technology of automobile engine and treatment method, which is applied in the field of treatment of automobile engine cutting fluid wastewater, can solve the problems of unstable treatment effect, high operating cost, poor operating environment, etc., achieve reasonable design of process steps, reduce investment cost, and reduce use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

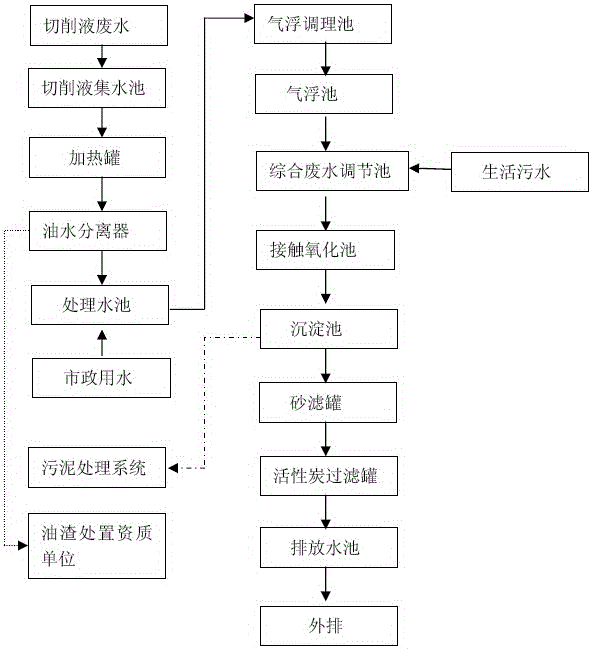

Method used

Image

Examples

Embodiment 1

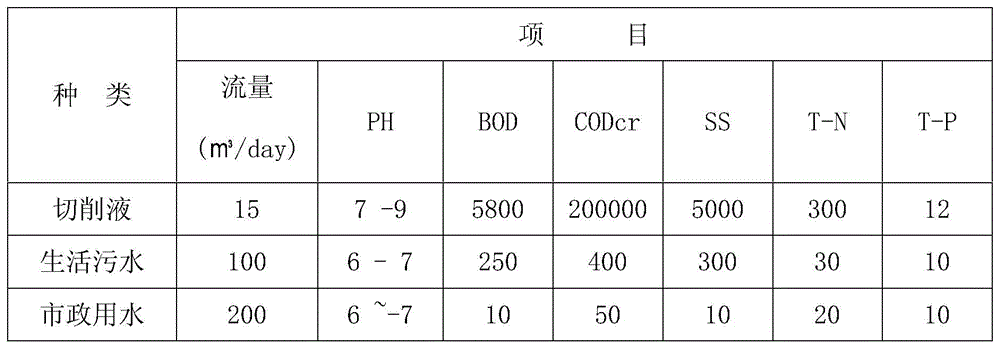

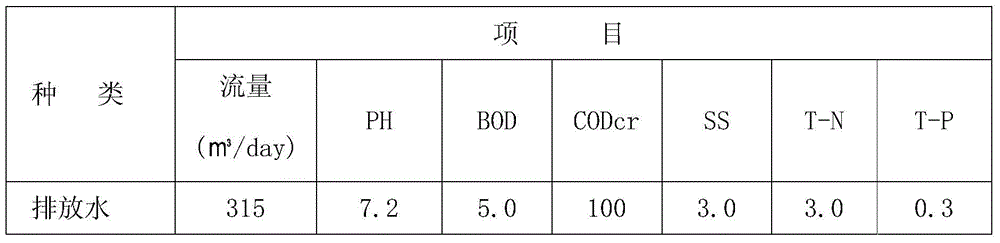

[0028] Method of the present invention carries out as follows:

[0029] a. The cutting fluid wastewater is discharged from the workshop into the collection pool, and the cutting fluid wastewater is sent to the heating device through the lifting pump in the pool. The steam is heated to 90°C and kept for 14 hours to break the emulsion of the wastewater, and then pump the wastewater after demulsification into the The oil-water separator realizes the separation of oil and water; the grease scum is collected by the oil scraper and sent to a qualified grease processing unit for safe disposal;

[0030] b. Add municipal water and wastewater to the waste water after oil-water separation in step a according to the ratio of waste water: municipal water waste water = 1:4 volume parts, then use sodium hydroxide to adjust the pH value of the mixed solution to 9, and then use the waste water : flocculant = 100: 0.95 integral ratio to add polyaluminum chloride flocculant, after adding floccul...

Embodiment 2

[0037] Method of the present invention carries out as follows:

[0038] a. The cutting fluid wastewater is discharged from the workshop into the collection pool, and the cutting fluid wastewater is sent to the heating device through the lifting pump in the pool. The steam is heated to 100 ° C and kept for 12 hours to break the wastewater, and then pump the demulsified wastewater into the The oil-water separator realizes the separation of oil and water; the grease scum is collected by the oil scraper and sent to a qualified grease processing unit for safe disposal;

[0039] b. Add municipal water and wastewater to the waste water after oil-water separation in step a according to the ratio of waste water: municipal water waste water = 1:6 volume parts, then use sodium hydroxide to adjust the pH value of the mixed solution to 8, and then follow the waste water : flocculant = 100: 1.05 integral ratio to add polyaluminum chloride flocculant, after adding flocculant, add anionic pol...

Embodiment 3

[0043] Method of the present invention carries out as follows:

[0044] a. The cutting fluid wastewater is discharged from the workshop into the collection pool, and the cutting fluid wastewater is sent to the heating device through the lifting pump in the pool. The steam is heated to 95°C and kept for 13 hours to break the emulsion of the wastewater, and then pump the wastewater after demulsification into the The oil-water separator realizes the separation of oil and water; the grease scum is collected by the oil scraper and sent to a qualified grease processing unit for safe disposal;

[0045] b. Add municipal water and wastewater to the waste water after oil-water separation in step a according to the ratio of waste water: municipal water waste water = 1:5 parts by volume, then use sodium hydroxide to adjust the pH value of the mixed solution to 8.5, and then follow the waste water : flocculant = 100: 1.0 integral ratio to add polyaluminum chloride flocculant, after adding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com