Treatment method for potassium clavulanate production wastewater

A technology for potassium clavulanate and waste water production, which is applied in biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., which can solve the problems of large land occupation, large investment, and high treatment cost, and reduce construction investment , High processing efficiency, reasonable combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

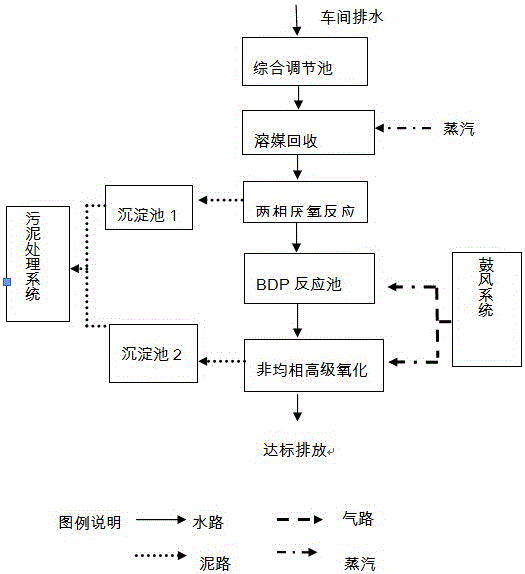

Image

Examples

Embodiment 1

[0039] A pharmaceutical group company produces 180 tons of potassium clavulanate per year, and the total amount of sewage generated every day is about 3,000 cubic meters. The production of potassium clavulanate undergoes fermentation reaction, membrane filtration, solvent extraction, activated carbon decolorization, salt formation, and purification processes to produce high-concentration refractory organic wastewater containing a large number of pollutants: 1) Organic load: COD up to 15000mg / L, NH3- The N content exceeds 350mg / L; 2) The salt content reaches 5000mg / L; 3) The residual organic solvent ethyl acetate; 4) The color is heavy and the smell is heavy.

[0040] The production wastewater enters the comprehensive adjustment pool after being discharged from the workshop, and the solvent-containing wastewater passes through the recovery tower, and the COD is reduced to 4000mg / L.

[0041] In the two-phase anaerobic stage, the hydrolysis and acidification tank, in the hydrolys...

Embodiment 2

[0045] The processing method of this potassium clavulanate production waste water is carried out as follows:

[0046] a. Send potassium clavulanate industrial waste water to the recovery unit to recover ethyl acetate at 69.9°C;

[0047] b. Send the clavulanic acid potassium industrial waste water of a step through the recovery of ethyl acetate to the hydrolysis acidification tank, adjust the pH value to 9.0, and treat it with the hydrolysis acidification bacteria group in the hydrolysis acidification tank for 2 hours, then enter the anaerobic reactor, and Anaerobic flora including methanogens were treated for 48 hours;

[0048] c. Send the wastewater treated by anaerobic reaction in step b to the BDP treatment process, and control the dissolved oxygen of the wastewater to 0.1mg / L;

[0049] d. Send the wastewater treated by the BDP process in step c to the advanced oxidation process, first adjust the pH value of the wastewater to 3.5, and add hydrogen peroxide to the wastewate...

Embodiment 3

[0051] The processing method of this potassium clavulanate production waste water is carried out as follows:

[0052] a. Send potassium clavulanate industrial waste water to the recovery unit to recover ethyl acetate at 70.1°C;

[0053] b. Send the clavulanic acid potassium industrial waste water of step a through recovery of ethyl acetate to the hydrolysis acidification tank, adjust the pH value to 8.0, and then enter the anaerobic reactor for 4 hours in the hydrolysis acidification tank by including Anaerobic flora including methanogens were treated for 36 hours;

[0054] c. Send the wastewater treated by anaerobic reaction in step b to the BDP treatment process, and control the dissolved oxygen of the wastewater to 0.3mg / L;

[0055] d. Send the wastewater treated by the BDP process in step c to the advanced oxidation process, first adjust the pH value of the wastewater to 3.0, and add hydrogen peroxide to the wastewater according to the addition amount of 2.5ml / L and accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com