Method for treating wastewater generated by gas generator

A technology of gasifier and treatment method, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high removal rate of phenolic substances, low removal rate of harmful substances, Problems such as large energy consumption, to achieve the effect of reducing treatment costs, reducing environmental protection pressure, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

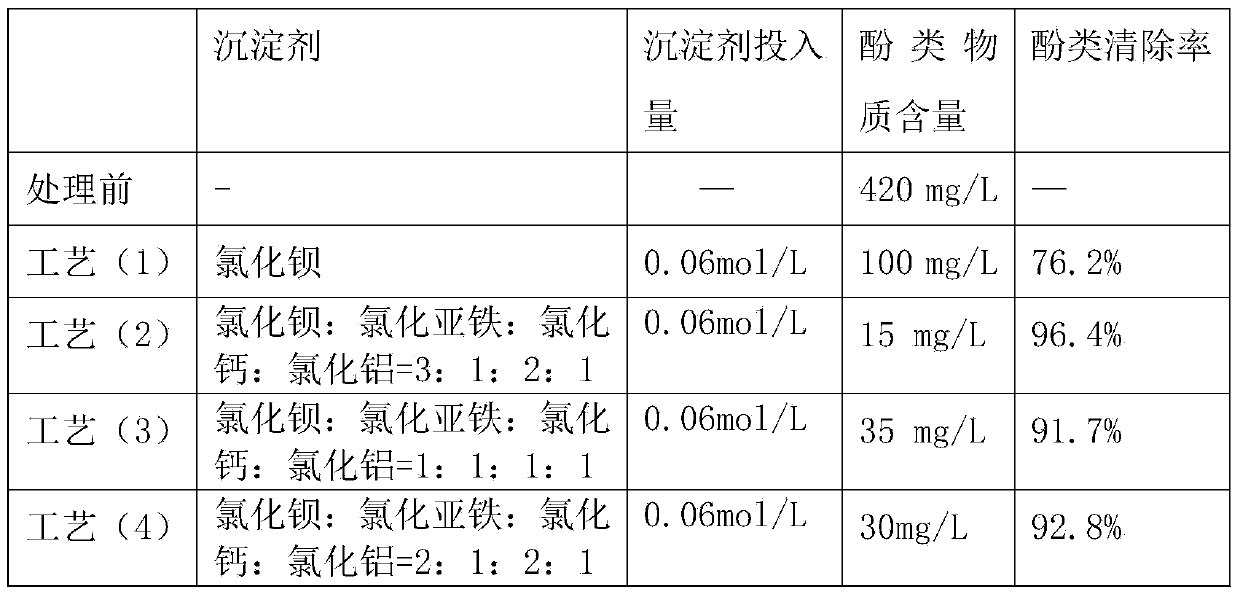

[0028] Embodiment 1 Wastewater treatment method of the present invention is to the influence of phenolic scavenging rate and COD scavenging rate

[0029] Take the waste water produced by a gas generator in a ceramic industry for treatment, and compare the effects of the two processes on dephenolization and COD:

[0030] Process (1): Use an adsorbent with a weight ratio of bentonite to activated carbon of 1:0.5 + ultrasonic treatment;

[0031] Process (2): Use an adsorbent with a weight ratio of bentonite to activated carbon of 1:0.8 + ultrasonic treatment;

[0032]Process (3): Use an adsorbent with a weight ratio of bentonite to activated carbon of 1:1 + ultrasonic treatment;

[0033] Process (4): Use an adsorbent with a weight ratio of bentonite to activated carbon of 1:0.8

[0034] Table 1 Effects of different treatment processes on phenolic scavenging rate and COD scavenging rate

[0035]

Phenolic content

COD

Phenol clearance

COD clearance rate...

Embodiment 2

[0042] Embodiment 2 The treatment method of the waste water produced by the coal gasifier of the present invention

[0043] Adopting the gasifier discharged by a certain ceramics factory produces waste water as treatment object, and its phenolic substance content is 750mg / L, and COD content is 1350mg / L; Adopt following treatment process to process described waste water, it comprises the following steps:

[0044] (1) Collect the phenol-containing waste water that the gasifier produces, and use a sieve to remove suspended matter, tar and insoluble impurities in the waste water, wherein the aperture of the sieve is 2mm;

[0045] (2) Add an adsorbent to the effluent in step (1) according to a weight-to-volume ratio of 2%, stand still for 2-5 hours after stirring, use an ultrasonic generator to ultrasonically treat the waste water, and filter it twice after standing still for 1.5 hours; The adsorbent is composed of bentonite and activated carbon, wherein the weight ratio of bentoni...

Embodiment 3

[0049] Embodiment 3 The treatment method of the waste water produced by the coal gasifier of the present invention

[0050] Adopting the gasifier discharged by a ceramic factory produces waste water as treatment object, and its phenolic substance content is 790mg / L, and COD content is 1380mg / L; Adopt following treatment process to process described waste water, it comprises the following steps:

[0051] (1) Collect the phenol-containing waste water that the gasifier produces, and use a sieve to remove suspended matter, tar and insoluble impurities in the waste water, wherein the aperture of the sieve is 2mm;

[0052] (2) Add adsorbent to the effluent in step (1) according to the weight-to-volume ratio of 3.5%, stand still for 2-5 hours after stirring, use an ultrasonic generator to ultrasonically treat the waste water, and filter it for the second time after standing still for 2 hours; The adsorbent is composed of bentonite and activated carbon, wherein the weight ratio of ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com