Treatment method and apparatus of electroplating wastewater

A technology of electroplating wastewater and treatment methods, which is applied in the direction of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high cost and complicated process of electroplating wastewater treatment, and achieve low cost of treatment equipment and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A treatment method for electroplating wastewater, the method comprises the following steps in sequence:

[0035] (1) Remove the suspension and slick oil in the raw water by air flotation, and then adjust the pH of the treated electroplating wastewater to 3-4.

[0036] (2) Adding Fenton's reagent to the electroplating wastewater, a first-order Fenton reaction occurs, and the pH is adjusted to 8-9; specifically, the time for the first-order Fenton reaction is 1 hour.

[0037] (3) After the electroplating wastewater treated in step (2) is precipitated, the pH of the supernatant is adjusted to 4-6.

[0038] (4) Add Fenton's reagent to the supernatant obtained in step (3), a secondary Fenton reaction occurs, and the pH is adjusted to 9-10; specifically, the time of the secondary Fenton reaction is 45min-1.5h; preferably Yes, after adjusting the pH to 9-10, add bleach water to the electroplating wastewater, a cyanide breaking reaction occurs to remove cyanide, and then remov...

Embodiment 2

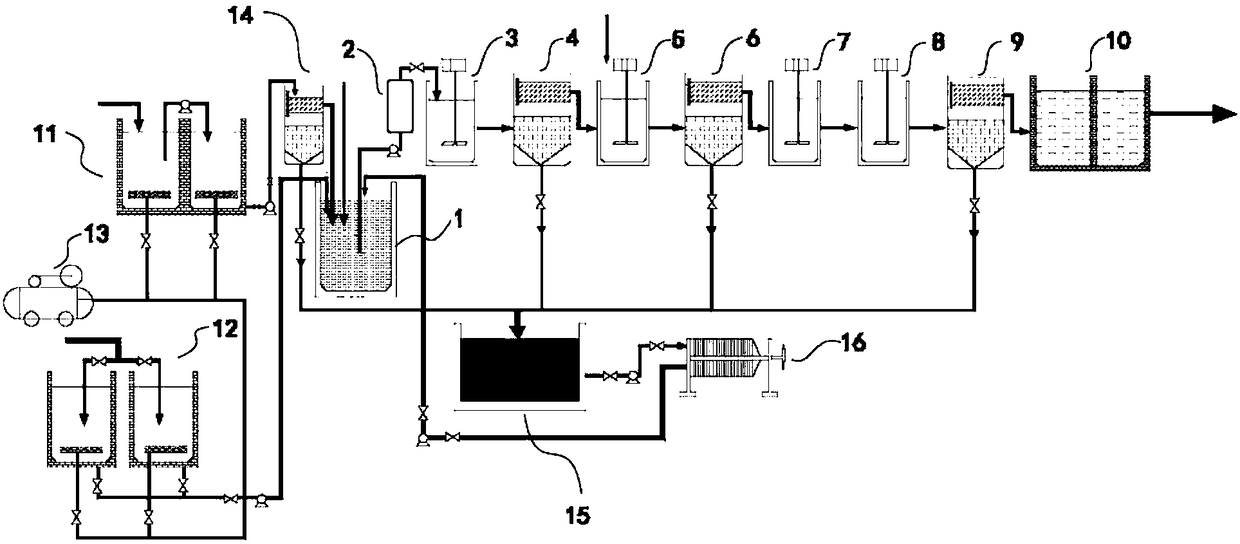

[0044] Such as figure 1 As shown, the application provides a treatment device for electroplating wastewater, comprising a comprehensive pool 1, an air flotation machine 2, a primary reaction pool 3, a primary sedimentation pool 4, a secondary reaction pool 5, and a secondary sedimentation pool arranged in sequence 6. Reduction reaction pool 7, pH callback pool 8, tertiary sedimentation pool 9 and biochemical pool 10.

[0045] Specifically, a cyanide breaking tank is also provided between the secondary reaction tank 5 and the secondary sedimentation tank 6 . Lift pumps are installed between the comprehensive tank 1 and the air flotation machine 2, between the primary reaction tank 3 and the primary sedimentation tank 4, and between the secondary reaction tank 5 and the secondary sedimentation tank 6. Among them, the primary sedimentation tank 4, the secondary sedimentation tank 6 and the tertiary sedimentation tank 9 are inclined plate sedimentation tanks.

[0046] Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com