Method for fixing CO2 and treating oil field sewage by using microalgae

A technology for oilfield sewage and microalgae, applied in sterilization/microdynamic water/sewage treatment, separation method, aerobic process treatment, etc., can solve the problems of high cost, immature large-scale breeding technology, and difficulty in large-scale application. , to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

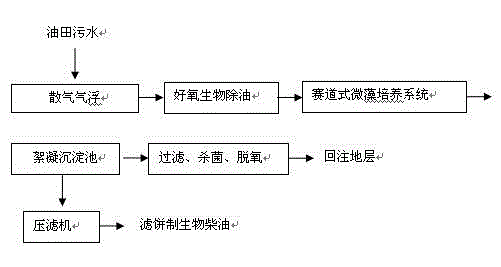

Image

Examples

Embodiment 1

[0022] a. Firstly, the oil field sewage of the oilfield sewage joint station is pretreated for oil removal by air flotation method. The pretreatment uses high gradient coalescence air flotation, and no chemical agents are added in the process of air flotation and oil removal to avoid damage to the oil field. Subsequent biological degreasing and microalgae cultivation produce toxicity; the oilfield sewage after most of the crude oil is removed by air flotation enters the activated sludge or biofilm degreasing treatment system to further remove crude oil, and the activated sludge or biofilm degreasing process According to TOC: N: P = 100: 5: 1 weight ratio, add N, P nutrient salt, the crude oil contained in the oil field sewage after activated sludge method or biofilm method treatment is lower than 1mg / L, and the TOC is less than 60 mg / L, COD is less than 150 mg / L;

[0023] b. First, the oilfield sewage treated with the aerobic biological method in step a overflows into the micr...

Embodiment 2

[0026] a. Firstly, the oil field sewage of the oilfield sewage joint station is pretreated for degreasing by air flotation method. Degreasing and microalgae cultivation produce toxicity; oilfield sewage after most of the crude oil is removed by air flotation enters the activated sludge method or biofilm deoiling treatment system to further remove crude oil, and the activated sludge or biofilm deoiling process is carried out according to the TOC: N: P = 100: 10: 1 weight ratio of N, P nutrient salt, the crude oil contained in the oil field sewage after activated sludge method or biofilm method treatment is less than 1mg / L, and the TOC in the sewage is less than 60 mg / L, COD less than 150 mg / L;

[0027] b. First overflow the oilfield sewage treated with the aerobic biological method into the microalgae biological cultivation system in step a, and CO 2Flue gas with a content of 15% is directly charged into the track-type microalgae cultivation system through the aeration system ...

Embodiment 3

[0030] a. Firstly, the oil field sewage of the oilfield sewage joint station is pretreated for oil removal by air flotation method. The pretreatment uses high gradient coalescence air flotation, and no chemical agents are added in the process of air flotation and oil removal to avoid damage to the oil field. Subsequent biological degreasing and microalgae cultivation produce toxicity; the oilfield sewage after most of the crude oil is removed by air flotation enters the activated sludge or biofilm degreasing treatment system to further remove crude oil, and the activated sludge or biofilm degreasing process According to TOC:N:P=100:8:1 weight ratio, N and P nutrient salts are added, and the crude oil contained in the oil field sewage after the treatment by the activated sludge method or the biofilm method is less than 1mg / L. TOC is less than 60 mg / L, COD is less than 150 mg / L;

[0031] b. First, the oilfield sewage treated with the aerobic biological method in step a overflows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com