Harnessing and resource recovering process of low concentration industrial oxymethylene waste water

A low-concentration technology for formaldehyde waste water, applied in water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste of resources, high equipment investment costs, and increased treatment costs , to achieve the effect of reducing equipment material requirements, reducing investment costs, and inhibiting side reactions

Inactive Publication Date: 2010-11-10

NANJING UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(2) A large amount of alkali metal oxides and strong inorganic acids need to be added during the conversion treatment of the mother liquor, which increases the treatment cost

(3) Formaldehyde is converted into formose sugar, which cannot be recycled and reused, and resources are wasted

(1) Under high-pressure operating conditions, the energy consumption of the process is high, the amount of condensed water is large, the operating cost is high, and the energy cannot be effectively comprehensively utilized;

(2) Because the feed liquid stays in the tower for too long, a large amount of formaldehyde is lost due to the formic acid generated by the Cannizzaro side reaction, and the recovery rate of formaldehyde is low. At the same time, the presence of formic acid requires that the acid resistance of the equipment in the separation system be improved, and the investment cost of the equipment is relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

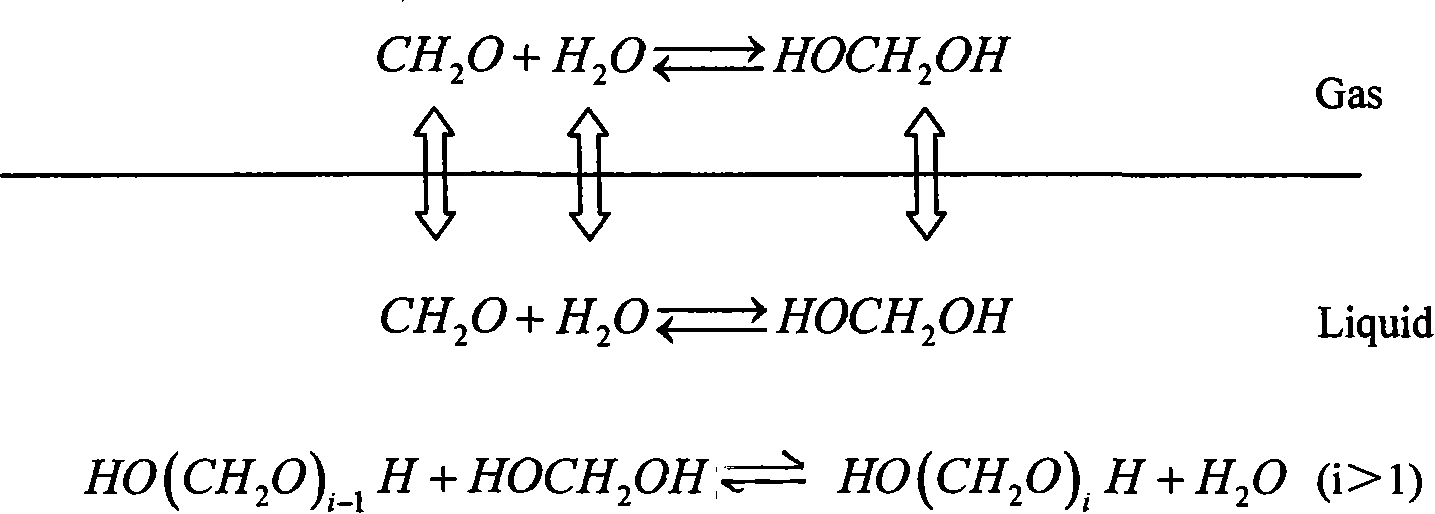

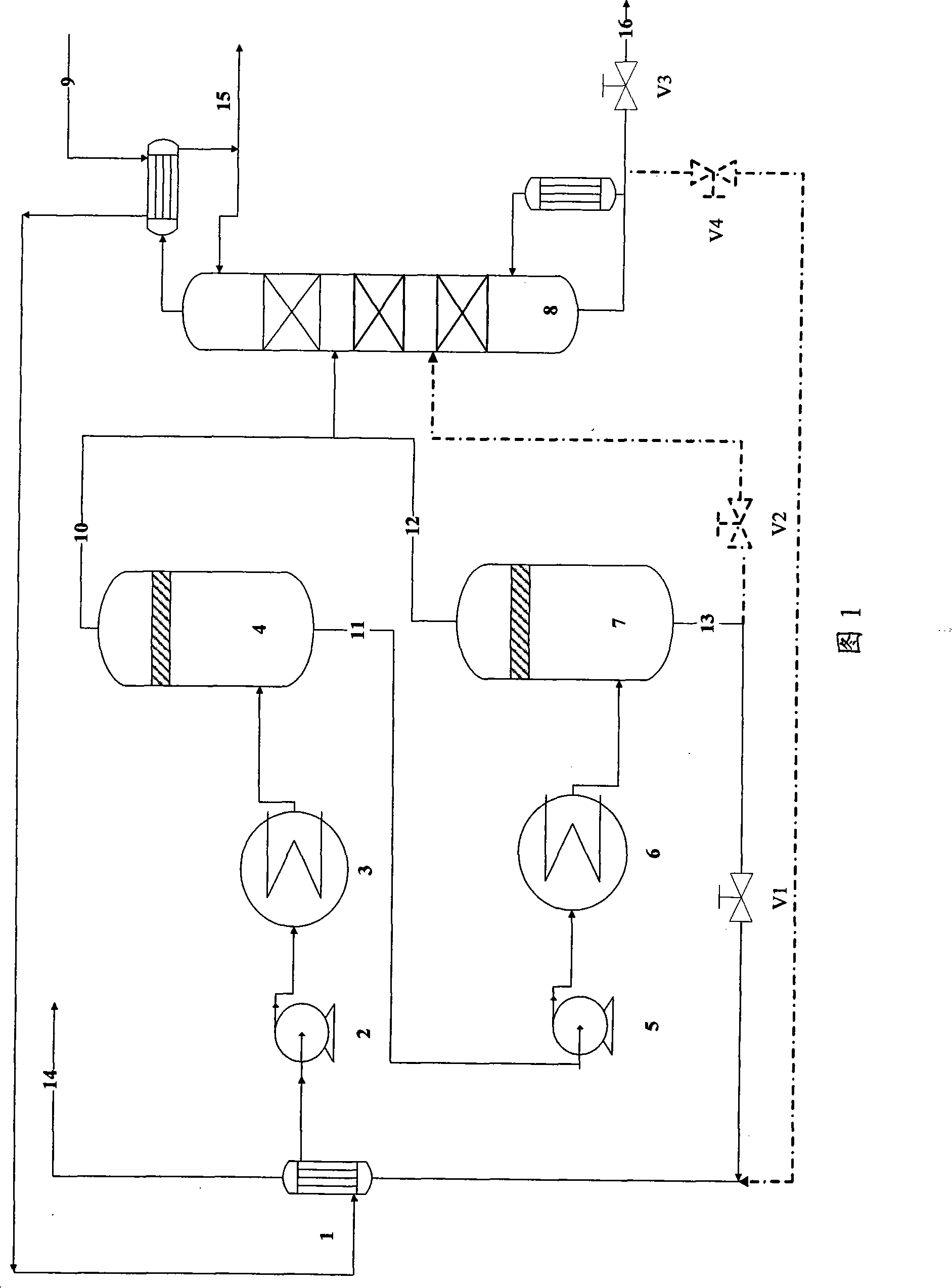

The invention relates to a treatment and resource reclamation technique for industrial formaldehyde wastewater with low concentration. The technique is as follows: the formaldehyde wastewater to be treated is preheated and pressurized and enters into a flash tank for flash evaporation so as to form two streams: a flashed formaldehyde steam and a flashed formaldehyde wastewater; after double-effect heat exchange and cooling are performed on the flashed formaldehyde wastewater through a preheater, the flashed formaldehyde wastewater is exhausted by combing up to the standards; the flashed formaldehyde steam enters into a low-pressure rectification tower for concentration; the operating pressure and the reflux ratio on the top of the tower are controlled, thereby the tower top can obtain 30 to 37 percent formaldehyde solution; and wastewater coming up to the standards is exhausted through a V3 valve on the lower side of a tower bottom. The technique has the advantages that: the hydrationbetween formaldehyde and water can be effectively controlled and the formaldehyde can be highly efficiently separated from the wastewater through flash evaporation at a high temperature; due to adoption of the flow of high-temperature flash evaporation and low-pressure rectification and concentration, the technique inhibits the Cannizzaro side reaction to the maximum degree, improves the recoveryrate of the formaldehyde, reduces the requirements of the technique on the material quality of equipment, and then reduces the investment cost.

Description

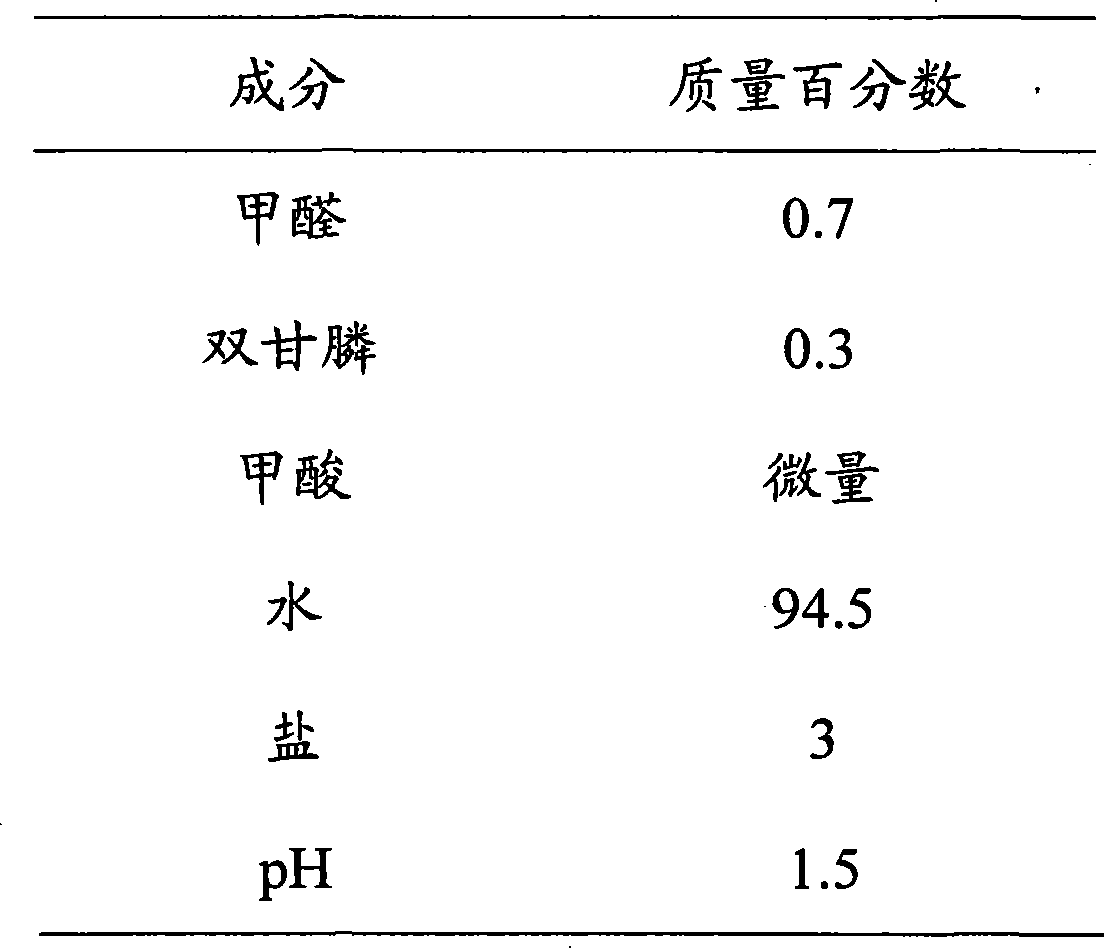

Treatment and resource recovery process of low-concentration industrial formaldehyde wastewater technical field The invention relates to a treatment and resource recovery process of low-concentration industrial formaldehyde wastewater. Background technique Formaldehyde is an important chemical raw material, which plays a decisive role in chemical synthesis fields such as chemical industry and pharmaceuticals, especially in the field of synthesis of pesticides and their intermediates. Since only 37% of commercially available formaldehyde is formaldehyde, and the rest are water, and because formaldehyde has high reactivity only in aqueous solution, even if solid formaldehyde is used as raw material, most of its reactions can only occur in aqueous solution, so in Industrial production process will inevitably produce low-concentration industrial formaldehyde wastewater. These wastewaters are difficult to treat with traditional biochemical methods because the presence of forma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/10C02F1/04C02F101/36

Inventor 张志炳李磊王辉孟为民

Owner NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com