A kind of rock wool directly prepared by melting sponge iron slag in an electric furnace and its preparation method

A technology of sponge iron and electric furnace, applied in the direction of glass manufacturing equipment, manufacturing tools, etc., can solve the problem of high energy consumption, achieve the effect of solving high energy consumption, saving energy consumption, and improving greenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the sponge iron involved in the embodiment is as follows:

[0036] (1) The iron ore is broken into particles with a particle size of about 3mm in a crusher;

[0037] (2) Put the crushed iron ore particles in step (1) into the tube furnace, control the temperature of the furnace to heat up to 1100°C at a rate of 10°C / min, and the furnace is always filled with N 2 as a shielding gas;

[0038] (3) Feed a reducing mixed gas for gas-solid reduction to obtain sponge iron; wherein, the main component of the reducing mixed gas is H with a molar ratio of 1:1 2 and CO, the temperature of the gas-solid reduction is kept at 1100° C., and the holding time is 2 hours.

Embodiment 1

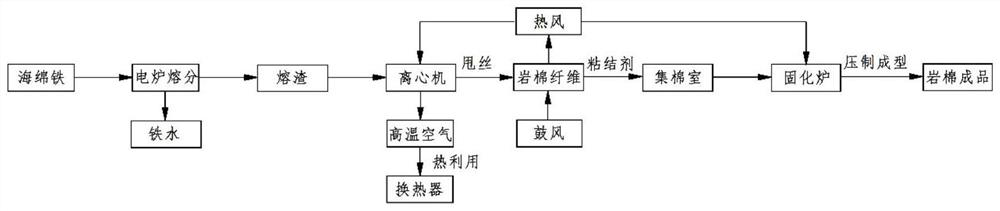

[0040] The present embodiment provides a kind of rock wool, and the preparation method of described rock wool is as follows (as figure 1 shown):

[0041] (1) Put the sponge iron into the electric furnace at a rate of 30kg / (MW·min), and melt it at 1500°C for 30 minutes to obtain molten iron and sponge iron slag; the temperature of the sponge iron slag is 1470°C;

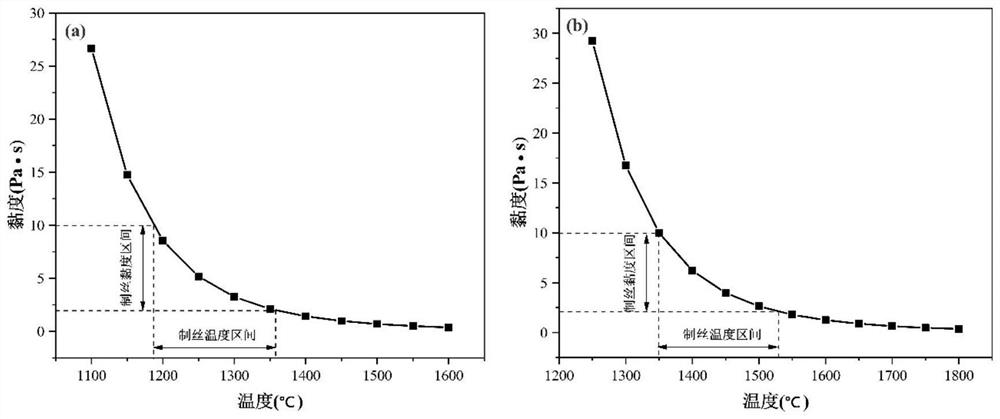

[0042] Wherein, the pseudo-binary phase diagram of the sponge iron slag is as follows figure 2 (a); In terms of mass percentage, the sponge iron slag comprises the following components:

[0043]

[0044] (2) The sponge iron slag at 1470°C is introduced into the spinning device (the main body is a three-roller centrifuge) through the drainage device. The speed configuration of the three-roller centrifuge is: 8000r / min for the distribution roller, 15000r / min for the first-stage acceleration roller, The secondary acceleration roller is 18000r / min; the high-pressure energy-carrying gas is passed through, and the roc...

Embodiment 2

[0050] The present embodiment provides a kind of rock wool, and the preparation method of described rock wool is as follows (as figure 1 shown):

[0051] (1) Put the sponge iron into the electric furnace at a rate of 30kg / (MW·min), and melt it at 1650°C for 60 minutes to obtain molten iron and sponge iron slag; the temperature of the sponge iron slag is 1600°C;

[0052] Wherein, the pseudo-binary phase diagram of the sponge iron slag is as follows figure 2 (b); In terms of mass percentage, the sponge iron slag comprises the following components:

[0053]

[0054] (2) The sponge iron slag at 1600°C is introduced into the spinning device (the main body is a three-roll centrifuge) through the drainage device. The speed configuration of the three-roll centrifuge is: 8000r / min for the distribution roller, 16000r / min for the first-stage acceleration roller, The two-stage acceleration roller is 20000r / min; the high-pressure energy-carrying gas is introduced, and the rock wool f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com