Catalyst distribution method and distribution device for coupling utilization of gas-solid fluidization reaction catalyst

A fluidized reaction and distribution device technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high reaction temperature, increased hydrocarbon partial pressure, and increased olefin, so as to reduce investment, realize coupled utilization, avoid mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

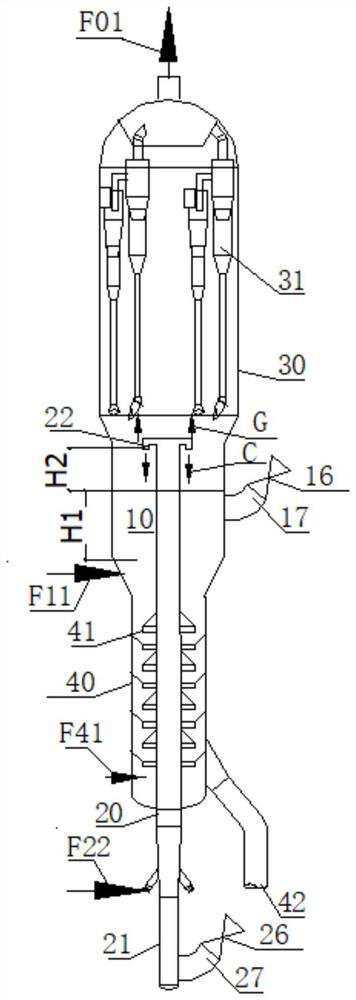

[0036] like figure 1 As shown, the implementation process is as follows:

[0037] The first reactor 10 is a turbulent fluidized bed reactor, the feedstock oil F11 enters from below the fluidized bed of the first reactor 10, and the regenerated catalyst enters the fluidized bed from the regenerated catalyst inlet pipe 17;

[0038] The second reactor 20 is a riser. The riser is in the middle of the first reactor 10 and the stripping section 40. Light hydrocarbons with a real boiling point lower than 360°C enter the second reactor 20 from the bottom as the second reaction raw material F22 to regenerate the catalyst. Enter from the regenerated catalyst inlet pipe A 27;

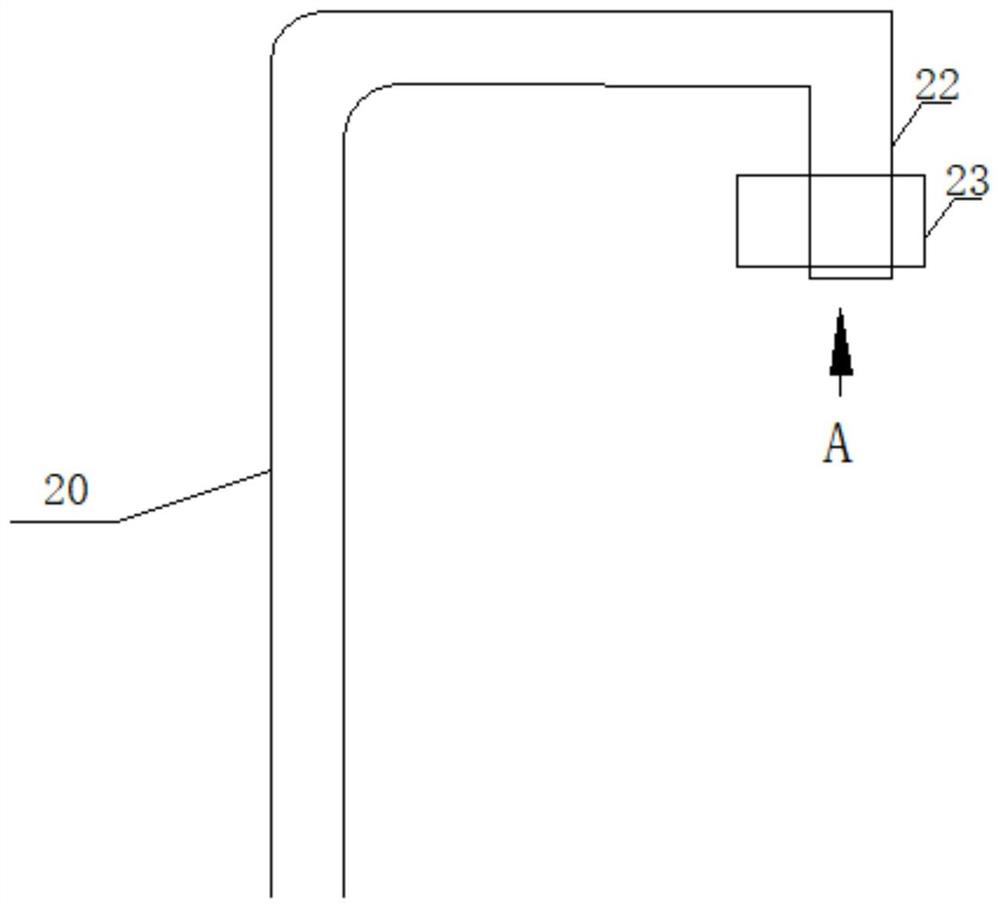

[0039] The outlet 22 of the second reactor 20 is turned downward, and the outlet 22 is above the catalyst in the fluidized bed of the first reactor 10. The reacted stream flows out of the second reactor 20 downward through the outlet 22, and the catalyst C gravity settles to the bottom. In the fluidized bed of t...

Embodiment 1

[0041] The first reactor 10 is a fluidized bed reactor, the regenerant enters the fluidized bed reactor, the reacted catalyst settles from the fluidized bed reactor 10 to the stripping section 40, the second reactor 20 is in the form of a riser, and the first reactor 20 is in the form of a riser. The second reactor 20 is arranged in the center of the first reactor 10 and the stripping section 40, and the superficial gas velocity (gas volume flow divided by the cross-sectional area) in the first reactor 10 is not greater than 1.5 m / s, preferably not greater than 1.0 m / s, the catalyst material level H1 in the fluidized bed is calculated according to the average density of the catalyst, the second reactor outlet 22 and the catalyst material level H2 in the first reactor 10 are designed to be 1.0-3.0 meters, and the second reactor outlet 22 is one or more; catalyst circulation and catalyst stripping are well known and will not be repeated here.

Embodiment approach 2

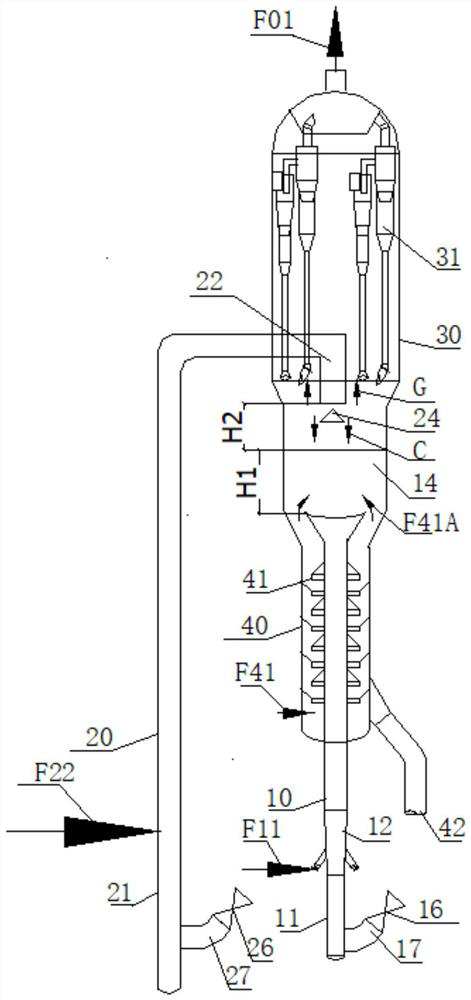

[0043] like figure 2 As shown, the implementation process is as follows:

[0044] The first reactor 10 is in the form of a common riser plus a fluidized bed, the fluidized bed reaction zone 14 is above, and the heavy feedstock oil F11 first enters the first reactor 10 in the riser section, and in the conical reaction section whose diameter gradually expands That is, the reaction is carried out in the gradually expanding reaction zone 12, and the raw material oil is converted into intermediate components mainly composed of gasoline and diesel oil, and then enters the fluidized bed reaction zone 14 upward, and the catalyst density is 200kg / m2. 3 Under the condition of the fluidized bed, the intermediate components are continuously cracked and converted into liquefied gas and dry gas components. The catalyst storage in the fluidized bed reaction zone 14 is based on the reaction catalyst weight hourly space velocity of 4-6 (1 / h) in this zone. It is determined that the fluidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com