Method for sewage treatment through co-agglomeration gas flotation method

A technology for copolymerization of air flotation and sewage, applied in flotation water/sewage treatment, multi-stage water treatment, chemical instruments and methods, etc., can solve the problems of long flocculation process, low effective utilization rate of microbubbles, short contact time, etc. Achieve the effect of increasing the probability of collision, strengthening the flocculation process and effect, and speeding up the coagulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

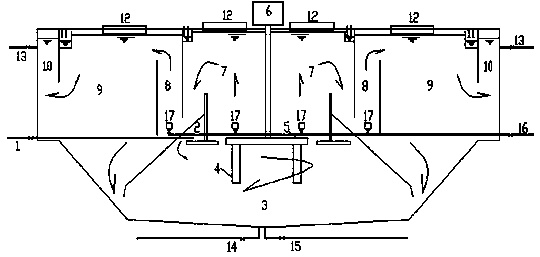

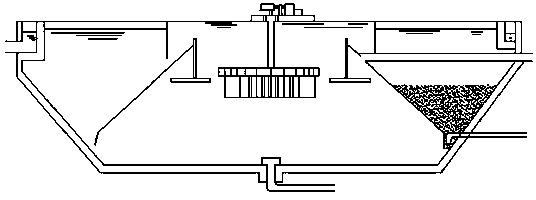

[0032] One: The structure of the air flotation clarifier

[0033] The air flotation clarifier of the present invention is as figure 1 and figure 2 As shown, the air flotation clarifier consists of a primary flocculation zone 3, a secondary flocculation zone 7, an air flotation contact zone 8, a solid-liquid separation zone 9, a clear water drainage zone 10, and a sludge return zone.

[0034] The specific structure is: the upper part of the overall structure of the air flotation clarifier is cylindrical, and the lower part is conical.

[0035] The primary flocculation zone 3 is located in the lower part of the air flotation clarifier, which is conical and equipped with a stirrer 6 and a stirring paddle 4 , as well as a water inlet pipe 1 and a water inlet distribution area 2 .

[0036] Above the primary flocculation zone, a secondary flocculation zone 7, an air flotation contact zone 8, and a solid-liquid separation zone 9 are distributed sequentially from the inside to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com