Method for performing microplastic separation on basis of gas floatation method

A separation method, microplastic technology, applied in solid separation, flotation, etc., can solve the problem of death and injury; on the other hand, microplastic ingestion into the body and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

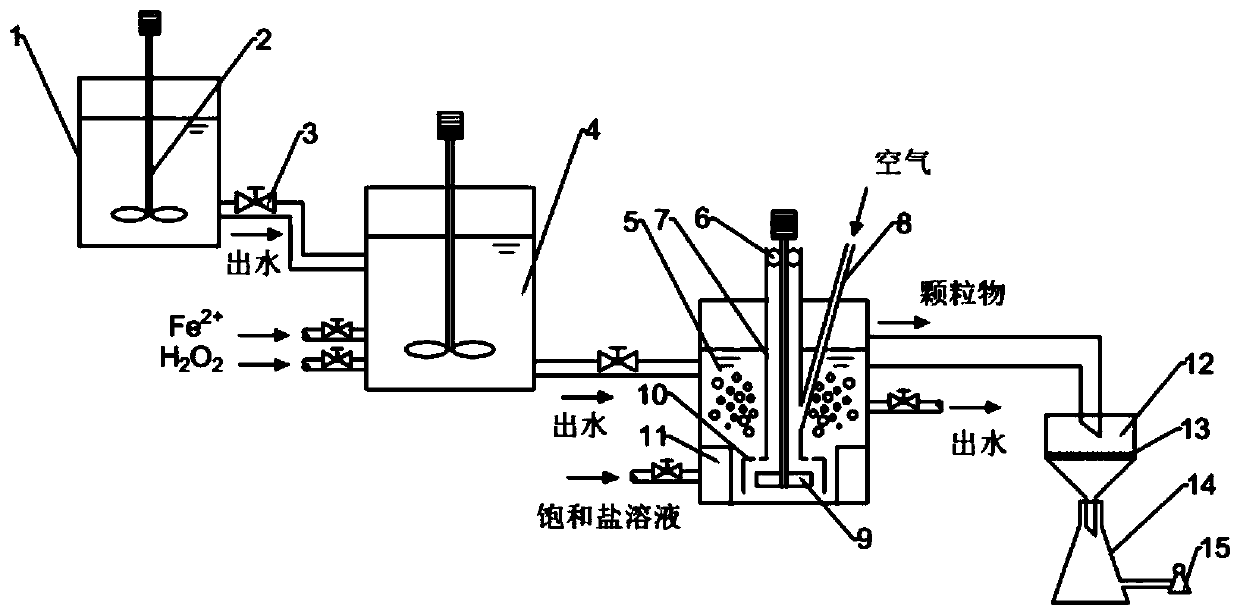

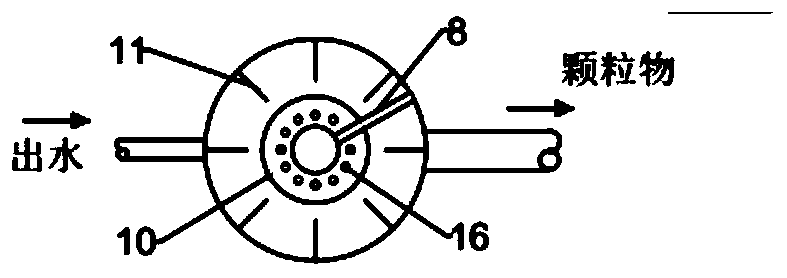

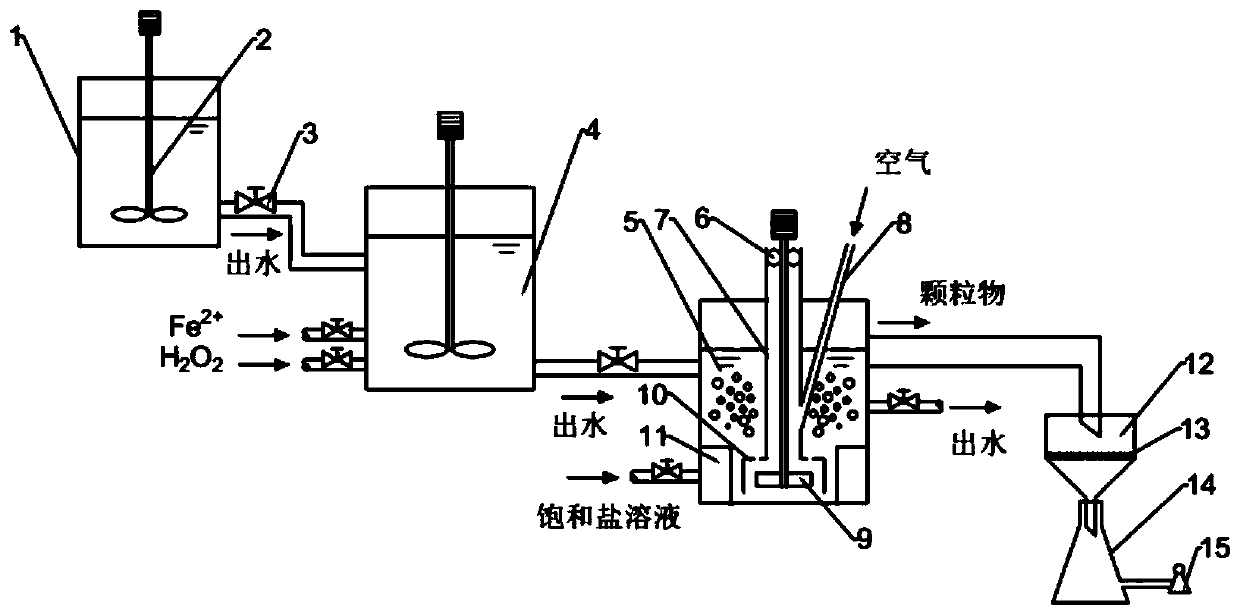

Method used

Image

Examples

Embodiment 1

[0028] A plurality of circular microplastic flakes with a diameter of 2 mm were weighed and fully dispersed in pure water to obtain a simulated dispersion liquid with microplastic pollution in stable suspension. The concentration of microplastic flakes in the simulated dispersion liquid was 1 g / L (176 / L), add the glycerol solution of triheptyl dodecyl ammonium iodide to the simulated dispersion liquid and stir well, the glycerol solution of triheptyl dodecyl ammonium iodide The mass concentration of alkyl ammonium iodide is 4%, and the mass volume ratio of the triheptyl dodecyl ammonium iodide glycerin solution and the simulated dispersion liquid is 30g: 1L,

[0029] Add hydrochloric acid aqueous solution with a solute mass fraction of 17% to the water obtained above and stir well. The mass volume ratio between the hydrochloric acid aqueous solution and the simulated dispersion liquid is 0.5g:1L, and then pass oxygen into the obtained water under stirring Produce aeration (ad...

Embodiment 2

[0041] Based on the device in the accompanying drawings of this plan, take the concentrated surface water body (before concentration, the microplastics in the surface water body are small flakes visible to the naked eye, and the average concentration is 1.3 / L; therefore, in the surface water body after concentration of 100 times The concentration of microplastics is 130 pieces / L. The 100-fold concentrated solution is sampled, filtered and weighed. The mass concentration of microplastics in the concentrated solution is 0.63g / L, which is convenient for calculating the amount of subsequent functional additives. Addition amount) Turn on the agitator 2 in the liquid storage tank 1 and stir fully, then open the valve 3, the water body will flow into the reaction tank 4 by itself, and feed FeCl at the same time 2 aqueous solution and H 2 o 2 Aqueous solution, control FeCl 2 and H 2 o 2 In the water body in the reaction tank 4, the amount concentration of the respective substances...

Embodiment 3

[0048] Take the soil sample polluted by microplastics, put the soil and pure water into the liquid storage tank 1 at a mass ratio of 1:10 for stirring and dispersion (the average concentration of microplastics in the water to be treated after dispersion in the liquid storage tank 1 is 14.4 / L), all the other cleaning operations are the same as in Example 2.

[0049] After sampling and testing, the average concentration of microplastics in the discharged purified water was 2.3 pieces / L.

[0050] For comparison:

[0051] On the basis of Example 3, without adding any triheptyl dodecyl ammonium iodide, by adding sodium chloride crystal powder to the reaction tank 4 for dissolution, the density of the water body in the air flotation tank 5 is the same as that of the subsequent agitation and aeration. Embodiment 3, all the other operations are the same as embodiment 3.

[0052] After sampling and testing, the average concentration of microplastics in the discharged purified water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com