Process for clarifying fish-farming sewage with electro-coagulation air flotation method

A technology of electrocoagulation air flotation and air flotation, which is applied in the direction of flotation water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., which can solve the application promotion of high investment and operation costs and affect the development of aquaculture industry , Destruction of the breeding ecological environment and other problems, to achieve the effect of simplifying the water purification process, simple management, and efficient solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

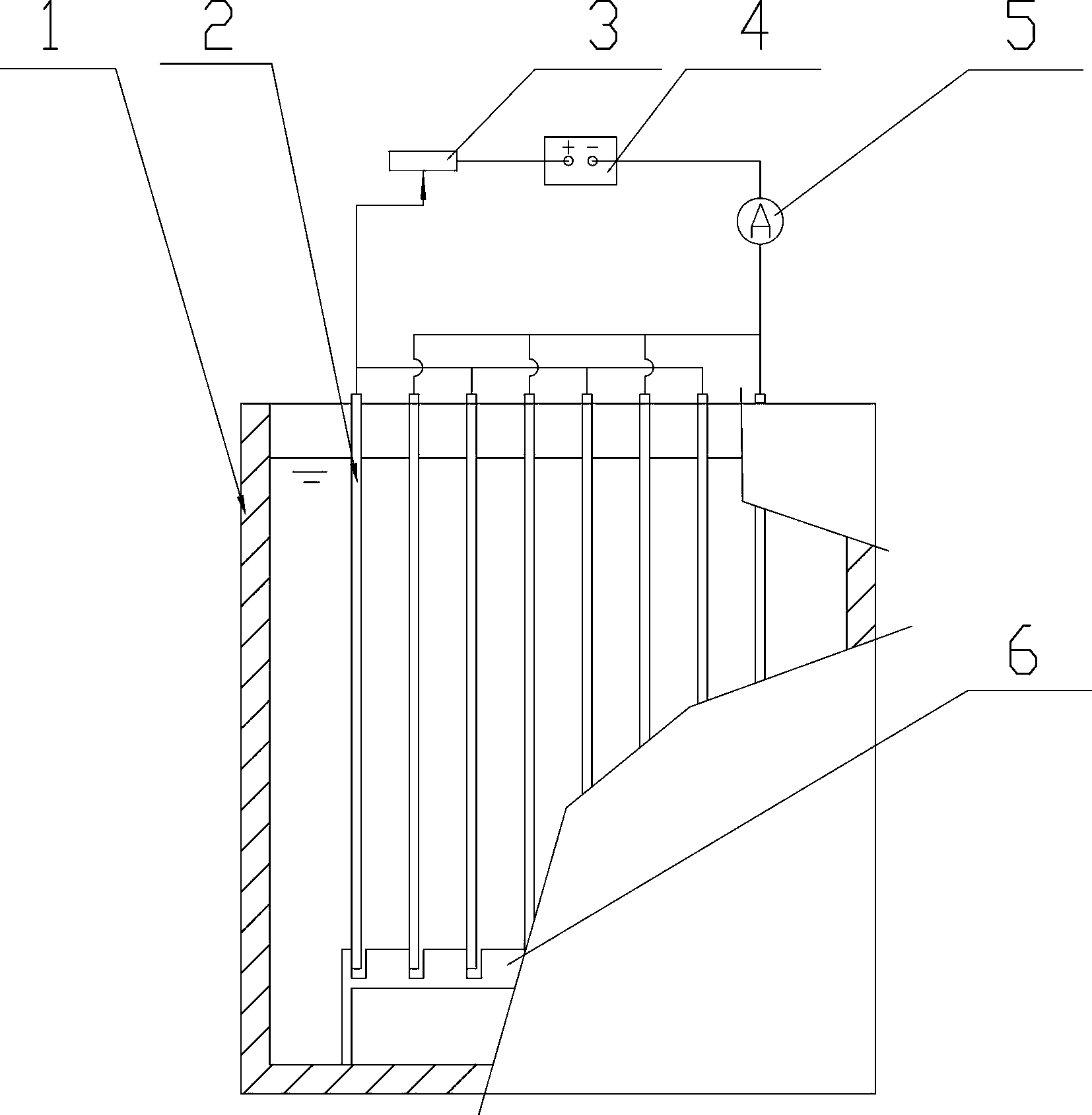

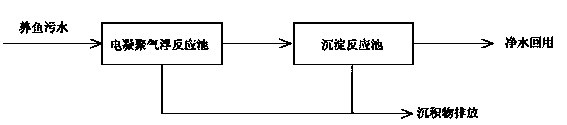

[0021] A process for purifying fish farming sewage by electrocoagulation air flotation, comprising an electrocoagulation air flotation reaction tank and a sedimentation reaction tank;

[0022] Electrocoagulation air flotation reaction tank structure: the bottom of the tank body 1 is provided with an insulating positioning bar 6, and a groove is provided on the positioning bar; several pole plates 2 are suspended and positioned on the tank wall by the upper cantilever, and the lower part of the pole plate 2 is positioned by the concave position of the positioning bar. The slots are separated; the distance between the pole plates 2 is 10 mm.

[0023] The unipolar parallel connection method is adopted between the plates: the first plate is the positive pole, the second plate is the negative pole, and they are arranged in sequence; the positive poles of all the unipolar plates are connected in parallel through the upper wire, and connected to the DC stabilized voltage through the v...

Embodiment 2

[0030] Through the adjustment of the variable resistor 3, the current density of the electrocoagulation air flotation reaction cell is controlled to 0.20 A / dm 2 .

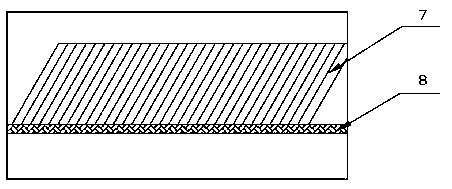

[0031] The bracket 8 is fixed on the pool wall or the bottom of the pool, and the plane area of the whole bracket is equal to the area of the sedimentation reaction tank; a number of inclined tube fillers are evenly arranged on the bracket, and there is a distance of 300-350mm between the inclined tube fillers and the bottom of the pool; The inclination angle of the horizontal plane is 60°; the filling rate of the upper space of the sedimentation reaction tank support is 75% when the inclined tube filler is filled.

[0032] Others are the same as embodiment 1.

[0033] Under the action of electrochemical reaction, the fish farming wastewater introduced into the electrocoagulation air flotation reaction tank will undergo flocculation and co-sedimentation, air flotation separation, redox, and the dirt generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com