Method for treating coal gas wastewater by adopting nitrogen floating device

A coal-to-gas and wastewater technology, applied in flotation water/sewage treatment, etc., can solve the problems of decreased biological treatment efficiency, strong microbial toxicity, and deepening of wastewater color, so as to reduce the operating cost of the method, improve the treatment efficiency, and reduce the load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

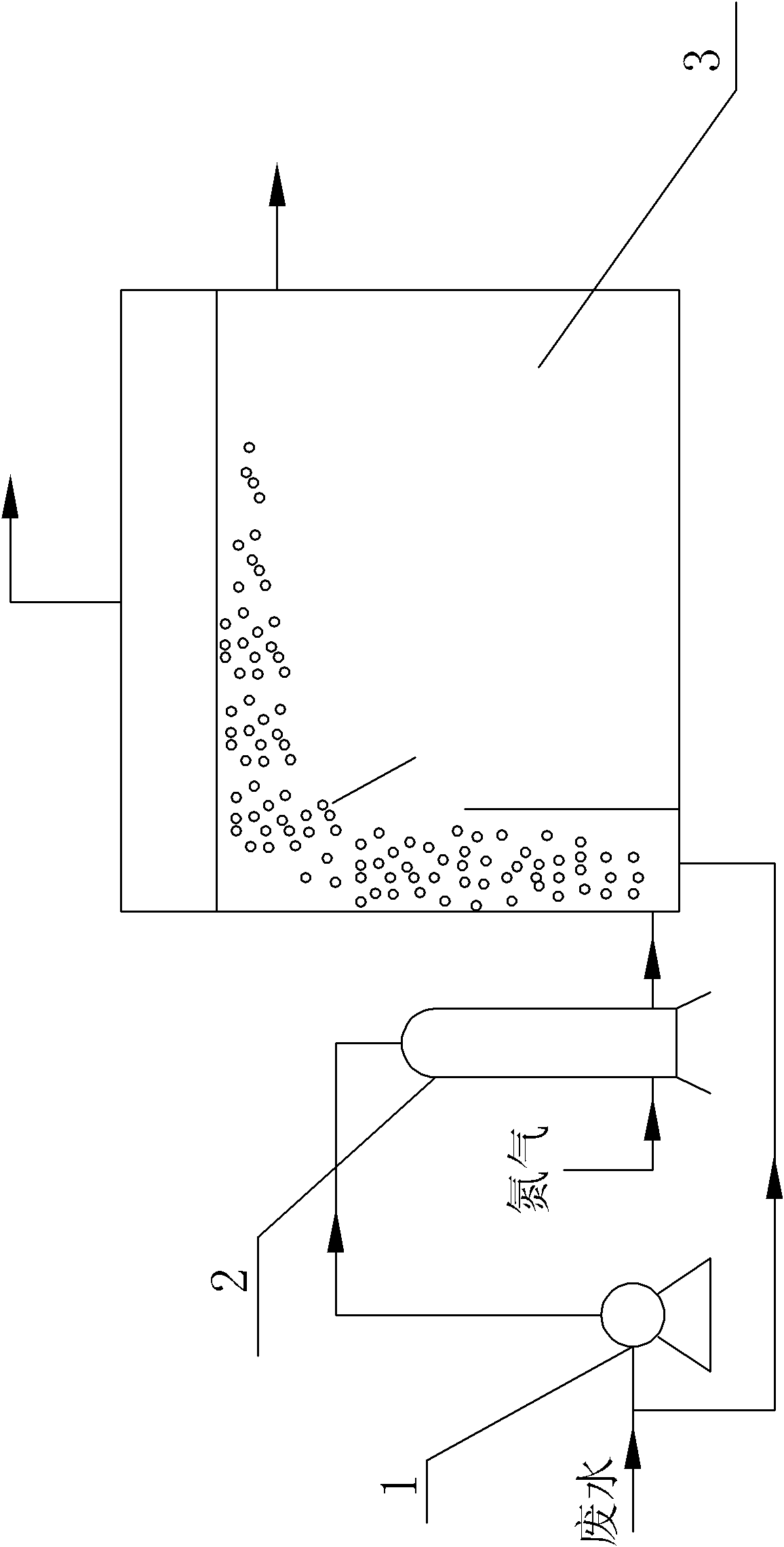

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment, the method of this embodiment comprises the following steps: step 1, waste water is divided into first part and second part, and the volume of first part accounts for 5%-50% of total waste water, and first part waste water is added through booster pump 1 After pressure, it is sent to the pressure dissolving tank 2, the nitrogen gas source enters the pressure dissolving tank 2, and the surface load of nitrogen is 2-6m 3 / m 2 h; step 2, under the action of pressure in the pressure dissolved air tank 2, nitrogen is dissolved in the waste water, and the waste water dissolved with nitrogen enters the air flotation pool 3 after being discharged from the pressure dissolved air tank 2; Step 3, dissolves in the air flotation pool 3 The pressure of the wastewater containing nitrogen is released, and the supersaturated nitrogen dissolved in the wastewater is released in the form of tiny bubbles, forming ...

specific Embodiment approach 2

[0013] Specific implementation mode two: in step two of the present embodiment, aluminum trichloride can be dropped into the air flotation tank 3, and the input amount is 1-100 mg / L, and this step can play the role of filtering waste water. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

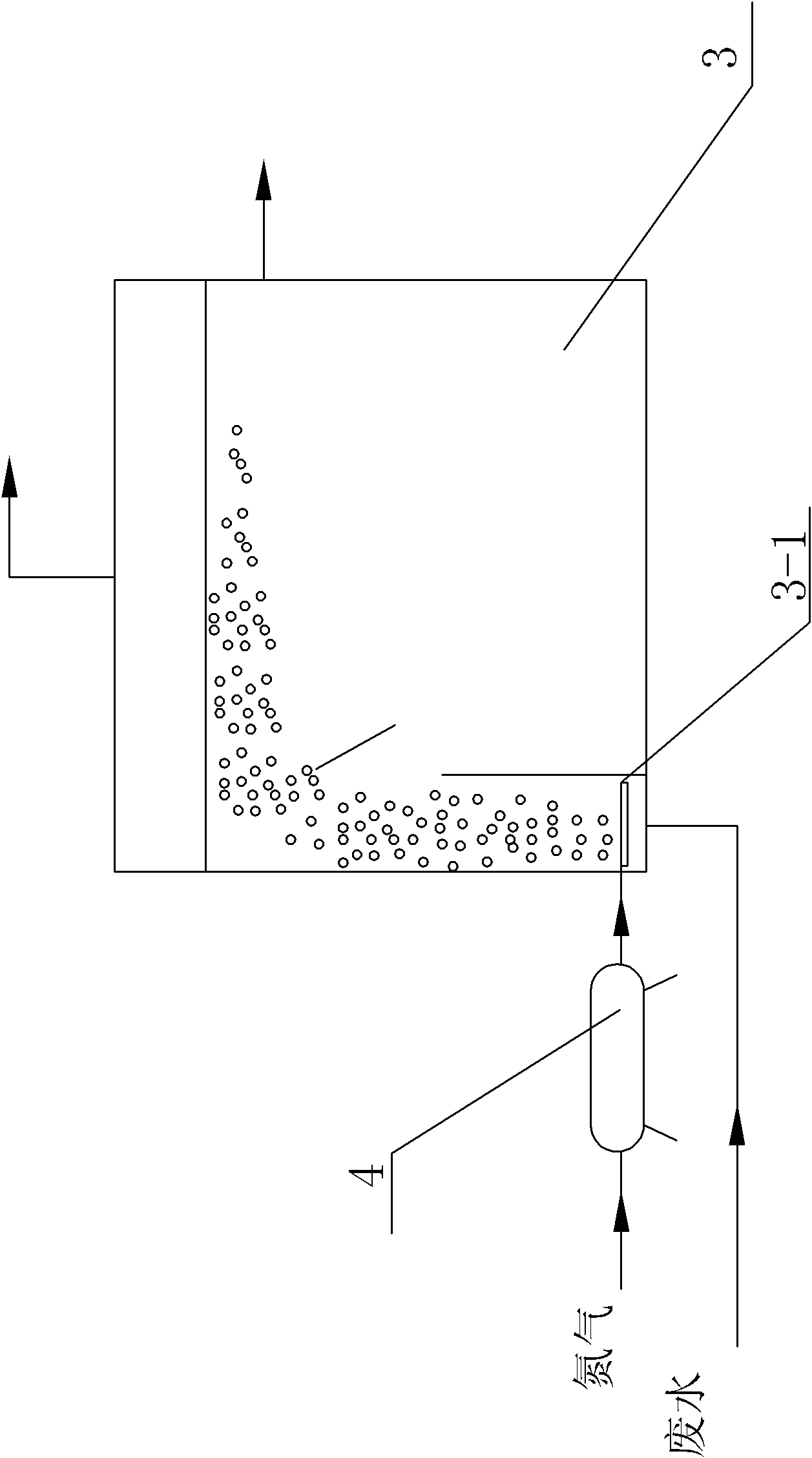

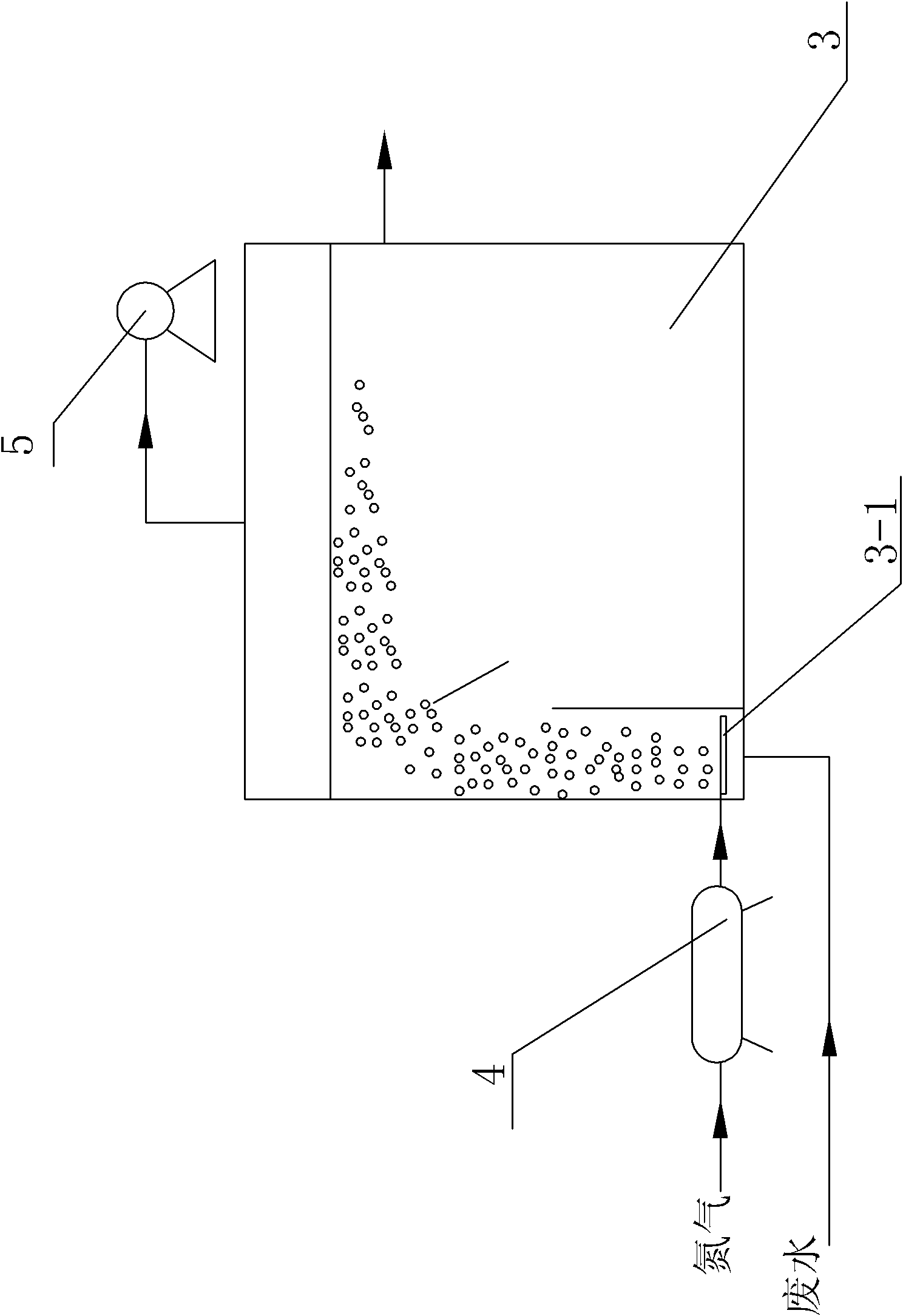

[0014] Specific implementation mode three: combination figure 2 Illustrate this embodiment, the method of this embodiment comprises the following steps: Step 1, waste water enters the bottom of air flotation tank 3, and waste water ascending flow rate is 1-2mm / s, and hydraulic retention time is 10-60min, and nitrogen is added through gas compressor 4 Pressure, compressed nitrogen escapes from the surface of the diffusion plate or diffusion tube 3-1 arranged at the bottom of the air flotation tank 3 in the form of tiny bubbles, and the surface load of nitrogen is 2-6m 3 / m 2 h; step 2, after the waste water in the air flotation tank 3 fully contacts the tiny bubbles formed at the bottom of the air flotation tank 3, the dispersed oil pollutants suspended in the waste water adhere to the surface of the tiny bubbles, forming composite particles with a density smaller than water Step 3: Under the action of buoyancy, the composite particles rise to the liquid surface with the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com