Novel process for comprehensively treating oily sludge of oil field

A comprehensive treatment and new process technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of high one-time investment, low pertinence, and narrow scope of application and other issues, to achieve the effect of low operating cost, strong pertinence, and wide processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

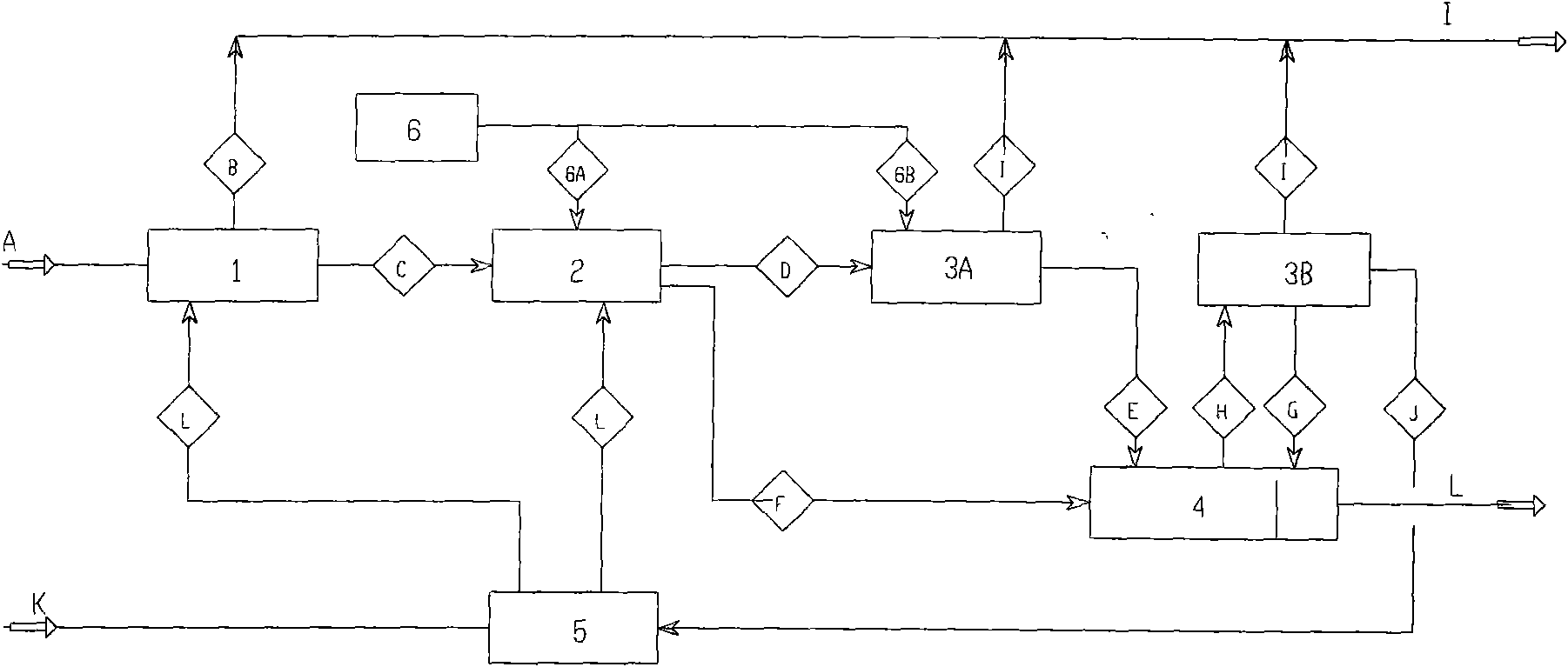

[0031] A new comprehensive treatment process for oily sludge in oil fields, such as figure 1As shown, it includes: the first step: sludge fluidization and pretreatment process; the second step: sludge conditioning process; the third step: mechanical separation process of oily sludge, and the separated water after the above process is used as From the process water L to the circulating water reuse process 5, the separated purified oil G enters the oil chamber of the oil-water separation device, and the solid particles, namely the centrifuged sludge I, are discharged through the screw conveyor.

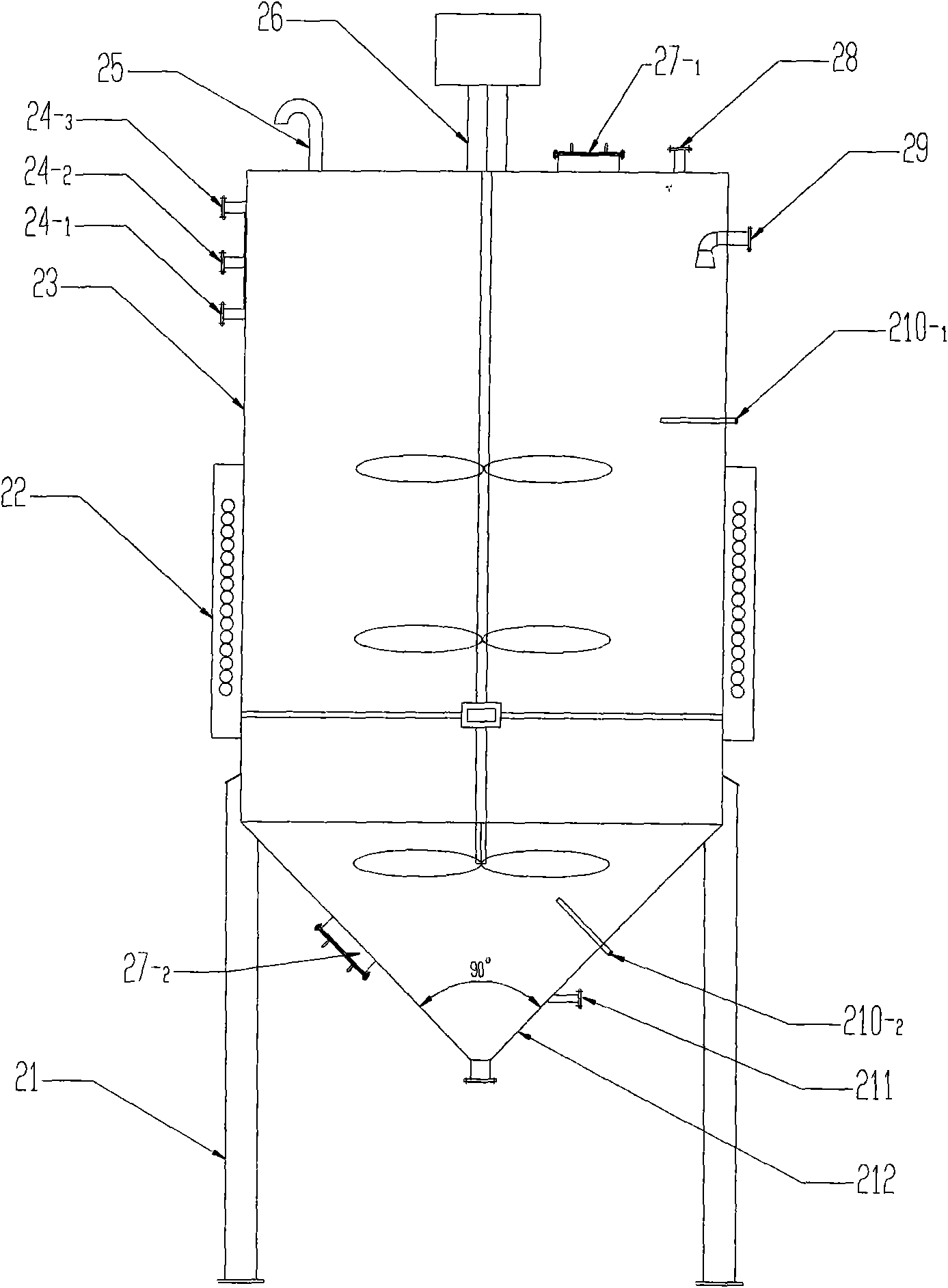

[0032] The first step: sludge fluidization and pretreatment process: includes: first: sorting step; second: self-cleaning drum type sorting step; third: aeration and sand setting heating step; The first one mentioned above: sorting step; the oily sludge first enters the collecting hopper of the feeding station, and is sorted through the stainless steel screen set on the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com