High strength strapping steel with tensile strength over 1,100 MPa and manufacturing method thereof

A technology of tensile strength and manufacturing method is applied in the field of high-strength strapping steel and its manufacturing, which can solve the problems of low strength performance of strapping steel, low production efficiency, and large environmental pollution, and achieve good product performance and production efficiency. High, low environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

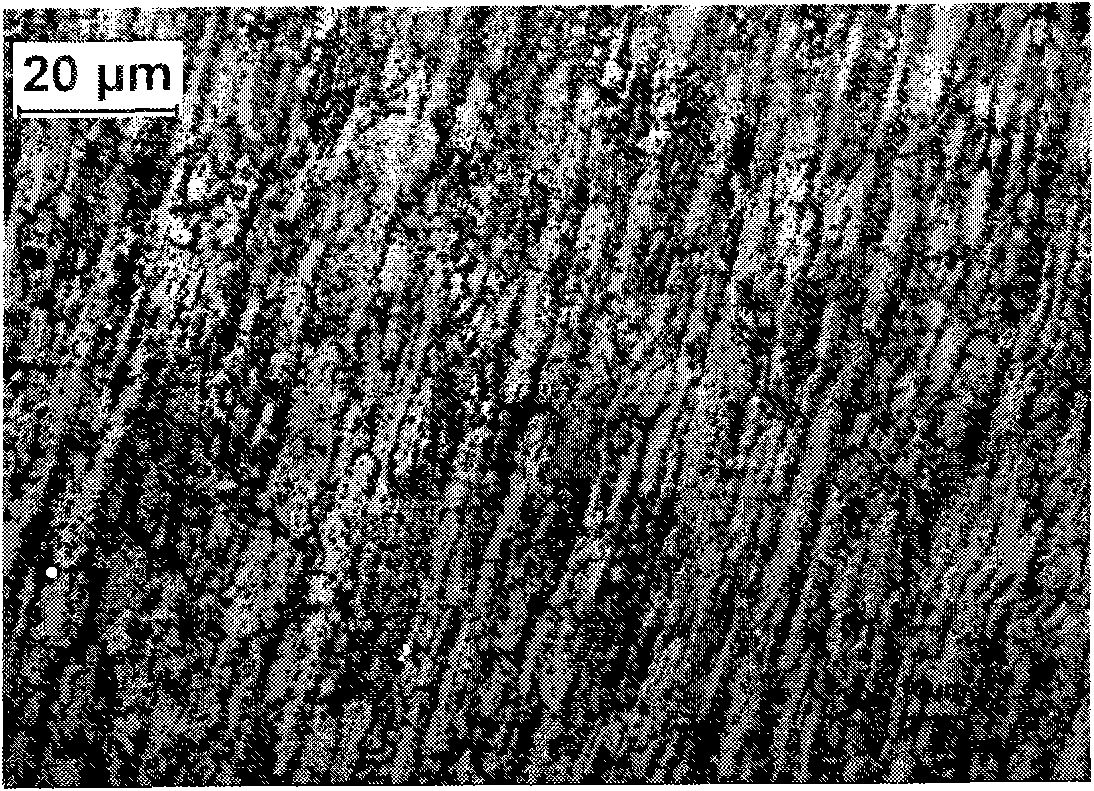

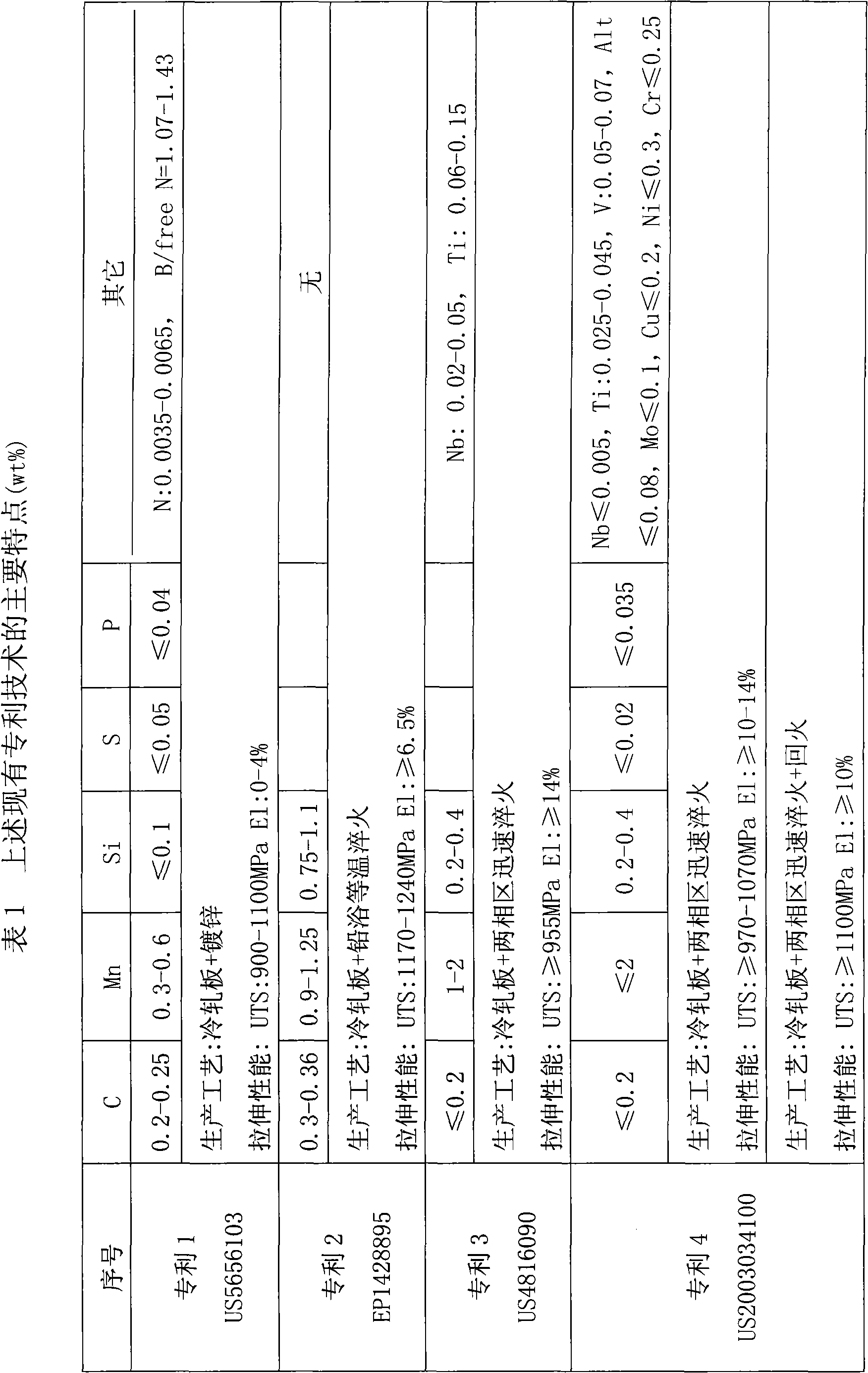

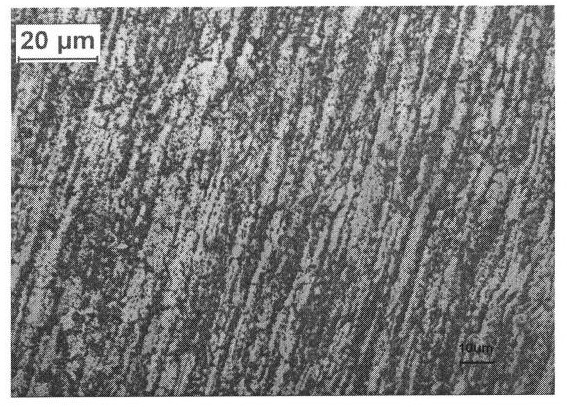

[0052] Following table 2 is the chemical composition of the embodiment of the high-strength strap steel with tensile strength higher than 1100MPa of the present invention, and table 3 is the process parameter that adopts correspondingly, and table 4 is the performance test result that carries out tensile test under room temperature condition . see again figure 1 , From the metallographic structure diagram, it can be clearly seen that the microstructure composed of recovered ferrite + tempered martensite with dispersed carbides is fine and uniform.

[0053] The chemical composition (wt%) of the embodiment of table 2

[0054] Example

C

mn

Si

S

P

1 and 2

0.26

1.05

0.23

0.011

0.037

3 and 4

0.29

1.24

0.22

0.0089

0.017

5 and 6

0.31

1.44

0.35

0.009

0.023

7 and 8

0.34

1.67

0.28

0.037

0.034

9 and 10

0.35

1.92 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com