Method for preparing active carbon from straw stalk

A technology for preparing activated carbon and rice straw, which is applied in the field of preparing activated carbon from rice straw, can solve the problems of low calorific value, low nutritional value, and unsuitability for returning to the field of rice straw, and achieves the advantages of simple preparation process, good adsorption performance, and good industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

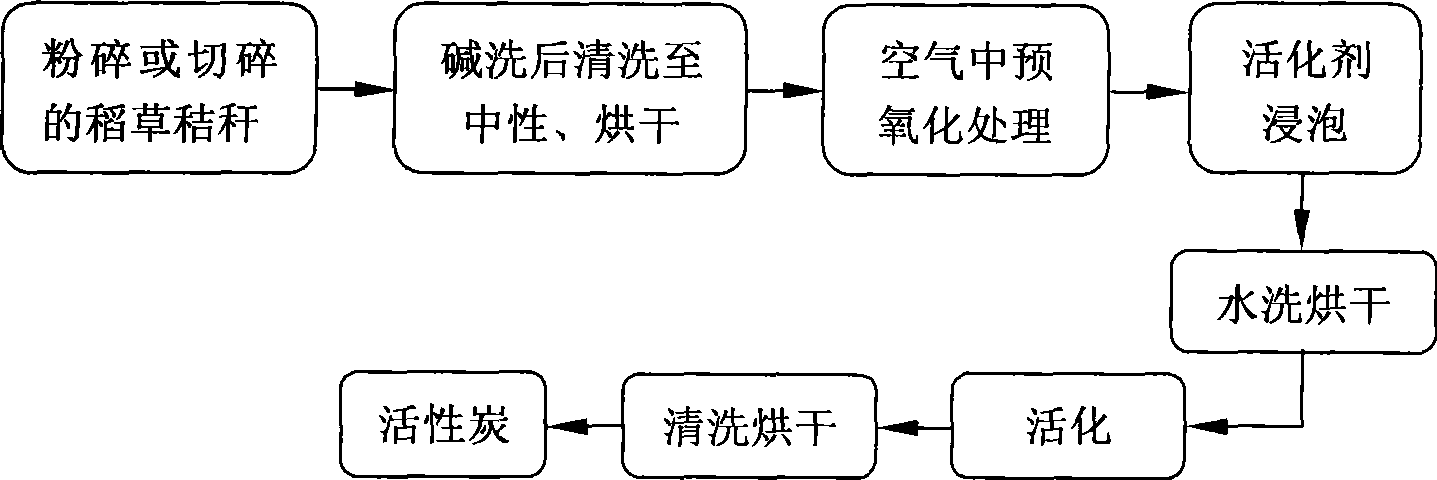

Method used

Image

Examples

Embodiment 1

[0024] Wash the collected rice straw with 2wt% NaOH solution, dry it at 105°C, and grind the rice straw into 100-mesh rice straw powder with a pulverizer, mix the rice straw powder with 30% diammonium hydrogen phosphate solution at a ratio of 1:3 After soaking for 12 hours, put the soaked rice straw powder into a vacuum drying oven for drying and put it into a tube furnace. Under the protection of a nitrogen flow of 50mL / min, the temperature is raised to 600°C at 20°C / min, and the At this temperature, it was activated at a constant temperature for 60 minutes. After activation, cool to room temperature and wash with distilled water to pH=6.5. Finally, put the clean product into a vacuum oven and dry it at 105°C to obtain activated carbon.

[0025] According to the national standard (GB / T 12496.10-1999) test, the adsorption value of methylene blue is 220mL / g, and the adsorption value of the national standard methylene blue is 120mL / g. The value is 1.83 times the first-level st...

Embodiment 2

[0027] Wash the collected rice straw with 2wt% NaOH solution, dry it at 105°C, cut the rice straw into a length of 3-5 cm with a cutting machine, soak the rice straw with 50% phosphoric acid solution at a mass ratio of 1:3 After 24 hours, put the soaked rice straw into a vacuum drying oven for drying and put it into a tube furnace. Under the protection of a nitrogen flow of 50mL / min, the temperature is raised to 700°C at 20°C / min, and at this temperature Constant temperature activation for 60min. After activation, cool to room temperature and wash with distilled water to pH=6.5. Finally, put the clean product into a vacuum oven and dry it at 105°C to obtain activated carbon.

[0028] Test according to national standard (GB / T 12496.10-1999), the adsorption value of methylene blue is 195mL / g, the adsorption value of national standard methylene blue is 120mL / g, the activated carbon product methylene blue adsorption of this example production The value is 1.63 times the first-le...

Embodiment 3

[0030] Wash the collected rice straw with 2wt% NaOH solution, dry it at 105°C, and grind the rice straw into 100-mesh rice straw powder with a pulverizer. The mass ratio was soaked for 12 hours, and the soaked rice straw powder was dried in a vacuum drying oven and then placed in a tube furnace. Under the protection of a nitrogen flow of 50mL / min, the temperature was raised to 700°C at 20°C / min, and the At this temperature, it was activated at a constant temperature for 60 minutes. After activation, cool to room temperature and wash with distilled water to pH=6.5. Finally, put the clean product into a vacuum oven and dry it at 105°C to obtain activated carbon.

[0031] Test according to national standard (GB / T 12496.10-1999), the adsorption value of methylene blue is 260mL / g, the adsorption value of national standard methylene blue is 120mL / g, the activated carbon product methylene blue adsorption of this example production The value is 3.17 times the first-level standard of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com